Introduction

This article provides an in-depth guide to bowl feeders.

You will learn about:

- What bowl feeders are

- How bowl feeders are used

- How bowl feeders work

- Different types of bowl feeders

- And much more...

Chapter One – What is a Bowl Feeder?

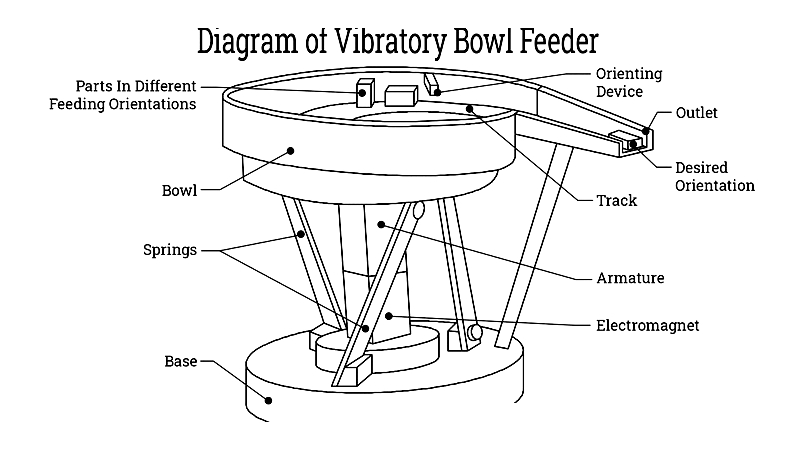

A bowl feeder is a vibrating device designed to supply small components to production lines for automation or to quickly sort bulk items. These feeders offer a reliable method for handling bulk materials while ensuring proper orientation for assembly processes.

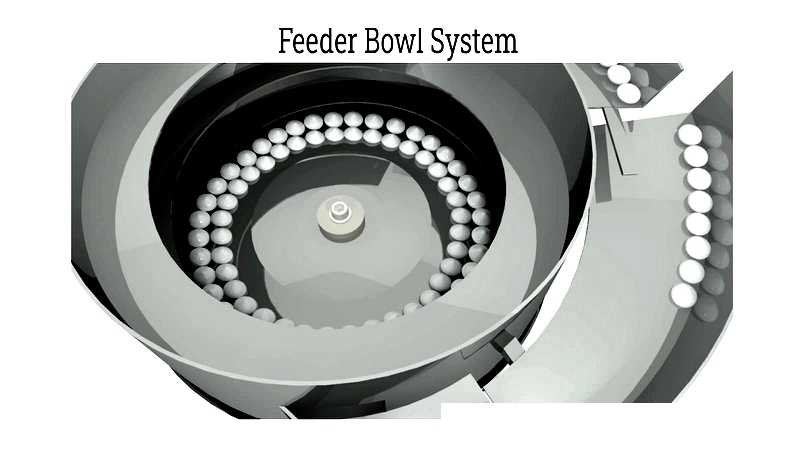

A complete bowl feeder system consists of a bowl mounted on a spring-loaded base with vertical motion. Vibration moves small parts upward through the bowl's tooling. Bowl feeders are versatile, capable of handling items as small as pills or as large as six cubic inches (15 cm³).

Despite their compact size, bowl feeders effectively organize, select, feed, and sort parts in a cost-efficient manner. Their performance is measured by factors like output rate, part orientation accuracy, and production floor space requirements. Some models can achieve output rates of up to 1600 parts per minute.

Chapter Two – How Bowl Feeders Are Used

Vibratory bowl feeders play a crucial role in industrial automation by efficiently organizing and orienting bulk parts for assembly processes. As essential automation components, they enhance manufacturing efficiency and production throughput across various industries including automotive, electronics, pharmaceuticals, and food production.

During manufacturing, bowl tooling is carefully designed to guide parts along the feeder bowl's circumference. The feeder track is customized based on part geometry and specific requirements like orientation and feed rate. Special coatings are often applied to reduce wear, minimize noise, and ensure smooth part movement.

Uses for Bowl Feeders

Feeding and Positioning Parts

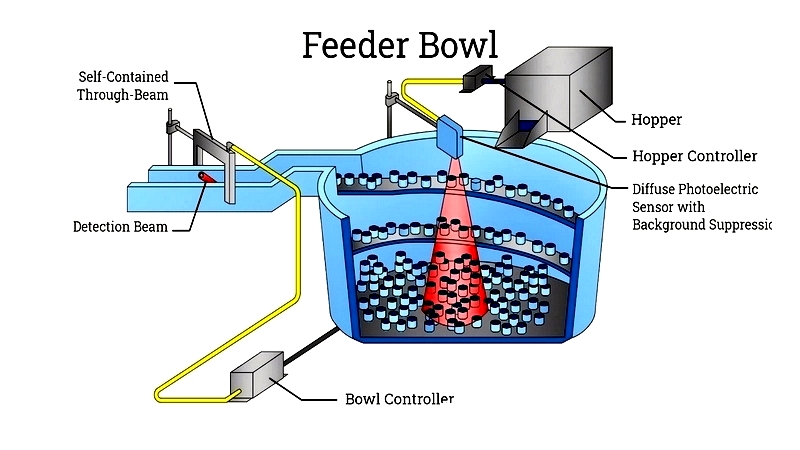

Bowl feeders can be configured with basic or advanced tooling to achieve precise part orientation and sorting. Their operation can be controlled via variable frequency controllers or PLCs to match automated process requirements, supporting quick changeovers for different component types.

Automating Manual Labor

Bowl feeders provide a reliable alternative to manual part feeding, enabling continuous operation while improving productivity. They are commonly used beneath hoppers to feed components like screws, caps, and electronic parts in automated production lines.

Counting Out Precise Parts

Counting bowl feeders deliver accurate batch feeding for packaging or assembly operations. These systems use PLCs and sensors to count components, with selector mechanisms to reject nonconforming items, improving production accuracy and inventory management.

Operators can easily set target quantities through programmable counting electronics, while diverter mechanisms ensure only correct batches proceed downstream.

Moving Parts With Pick and Place

In pick and place automation, bowl feeders deliver pre-oriented parts to workstations via linear inline feeders. This precision is critical for robotic assembly and electronics placement systems, where accurate positioning affects product quality.

Inline feeders maintain orientation before parts enter assembly cells, with sensors to identify and recirculate misaligned components, improving process reliability.

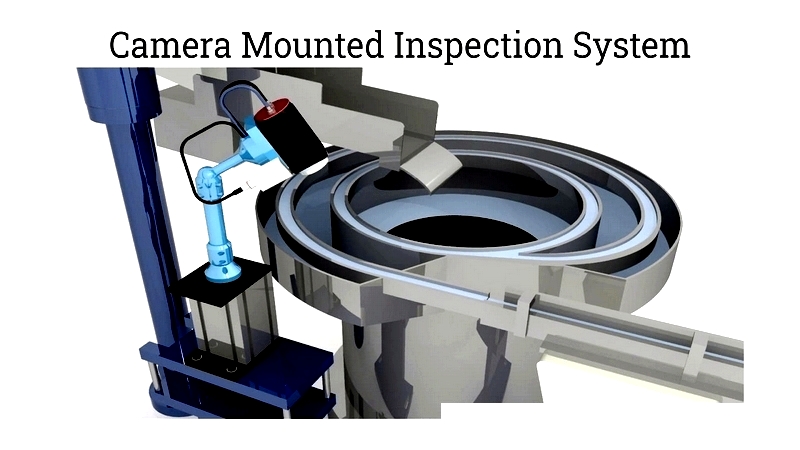

Inspecting and Detecting Parts

Vision inspection systems integrated with bowl feeders verify part orientation and quality. As parts exit the feeder, cameras and sensors analyze them against programmed parameters, rejecting any defective items.

This combination of automated feeding and inspection enhances process control, product quality, and traceability throughout production.

When selecting a bowl feeder system, consider feed rate requirements, part geometry, and integration with other automation equipment. Partnering with an experienced manufacturer ensures optimal design and long-term reliability, maximizing ROI for manufacturing operations.