Introduction

This article provides an in-depth exploration of water jet cutting technology.

You will gain insights into various aspects including:

- The fundamentals of water jet cutting

- The water jet cutting process

- Different types of water jet cuts

- Varieties of water jet cutting methods

- Applications of water jet cutting

- Water jet cutting equipment

- And additional relevant information

Chapter One – What is Water Jet Cutting?

Water jet cutting is an advanced manufacturing technique that employs high-pressure water streams, generated by specialized pumps, to create supersonic jets capable of cutting diverse materials. The water in this process reaches pressures up to 392 MPa and is forced through a precision-engineered nozzle, achieving velocities three times the speed of sound upon exit.

Pure water jet cutting, using water alone, is ideal for softer materials including wood, plastics, foam, paper, and rubber. When abrasives are added to the water stream, the cutting capability expands dramatically, enabling the processing of harder materials like titanium, stainless steel, aluminum, glass, ceramic, and concrete.

Chapter Two – How Water Jet Cutting Works

Water jet cutting represents a sophisticated precision manufacturing technology that employs high-pressure water streams, often enhanced with abrasives, to cut nearly any material with remarkable accuracy. Modern systems typically incorporate abrasive materials like garnet or aluminum oxide, significantly improving their capacity to cut hard substances such as metals, stone, glass, and composites. This versatile process allows manufacturers to create workpieces with exact specifications while avoiding thermal distortion or mechanical stress.

Compared to alternative machining processes like plasma or laser cutting, water jet technology offers superior edge quality and precision. It excels at intricate designs required in aerospace and automotive manufacturing, and is particularly effective for heat-sensitive materials. The high-velocity abrasive stream erodes material while maintaining cool temperatures, preserving material properties and producing clean edges that often require no additional finishing.

The Process of Water Jet Cutting

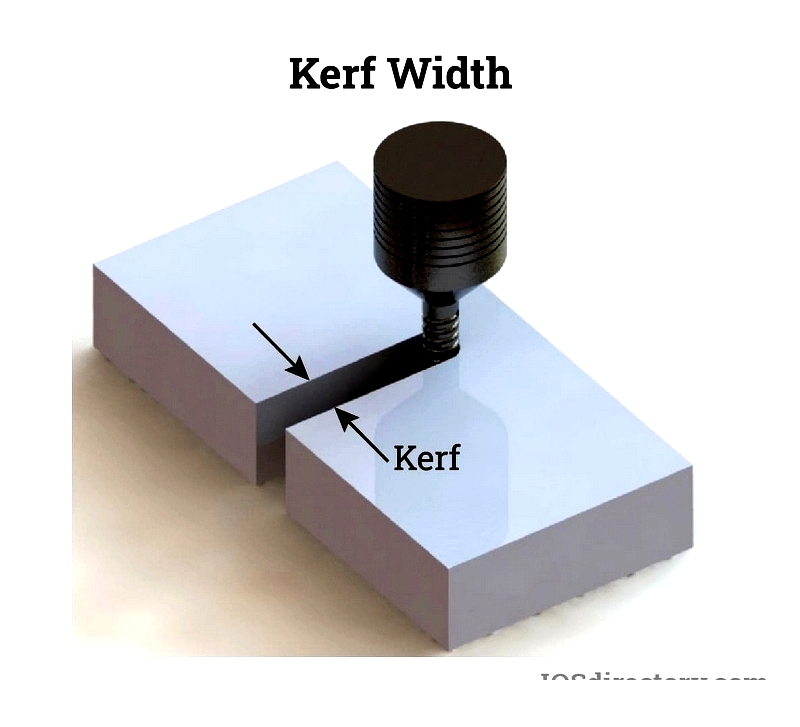

Measuring Kerf Width

Kerf width refers to the material removed during cutting. In water jet systems, this typically measures 0.04 inches or less. Precise kerf measurement is crucial for CNC programming, as it affects corner radii and final dimensions. Multiple factors influence kerf width, including material properties, cutting speed, and nozzle characteristics.

Accurate kerf compensation in CAD/CAM software is essential to meet dimensional tolerances. Neglecting this factor can result in unusable components, particularly in precision assemblies.

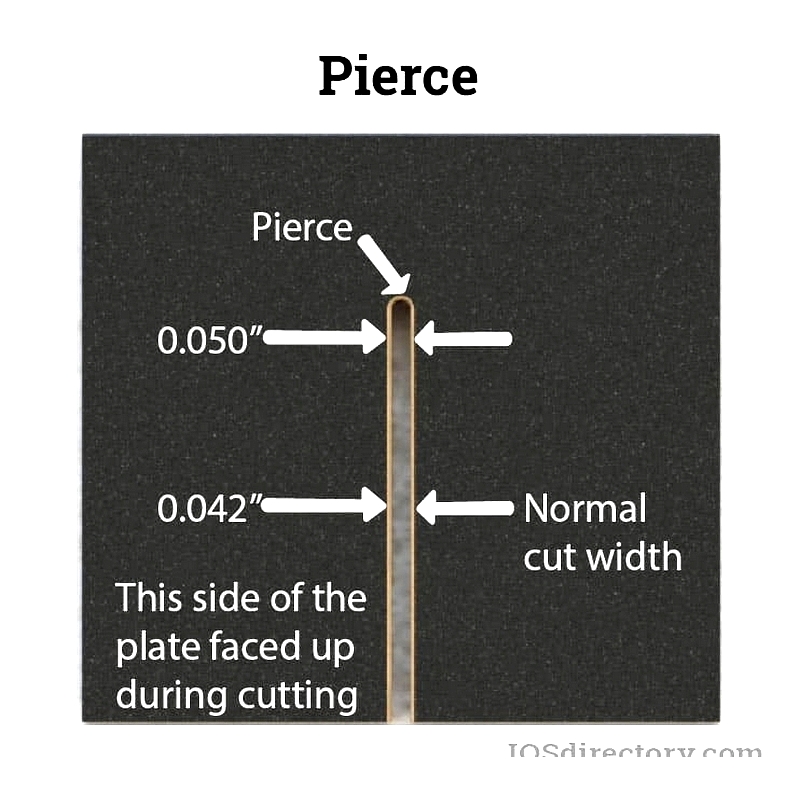

Initial Water Jet Piercing

The initial pierce cut tends to be wider and less precise than subsequent cuts. Various piercing techniques—stationary, linear, circular, or low-pressure—are selected based on material properties to minimize defects and waste in materials like composites or brittle substances.

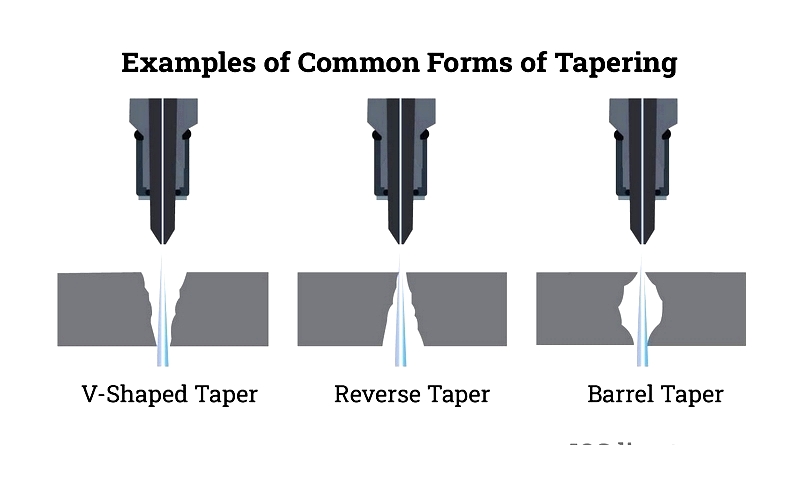

Tapering in Kerf Width

Tapering describes the variation in kerf width from top to bottom of a cut, typically forming a V-shape as jet energy decreases with depth. Managing taper is critical for precision components in aerospace, medical, and electronics applications.

Cutting speed affects taper characteristics—slow speeds may create reverse taper in soft materials, while thick materials might produce barrel taper. Advanced systems use dynamic head compensation to minimize taper effects.

While generally acceptable in industrial applications, taper compensation is essential for parts requiring exact tolerances and precision fits.

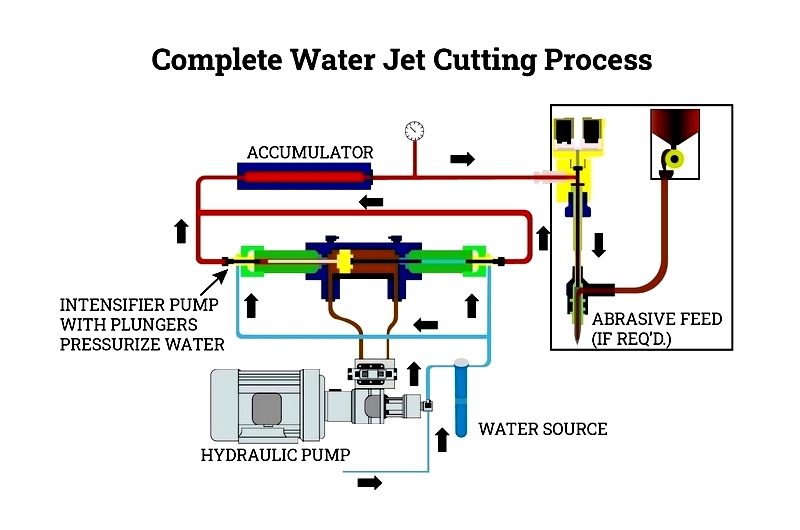

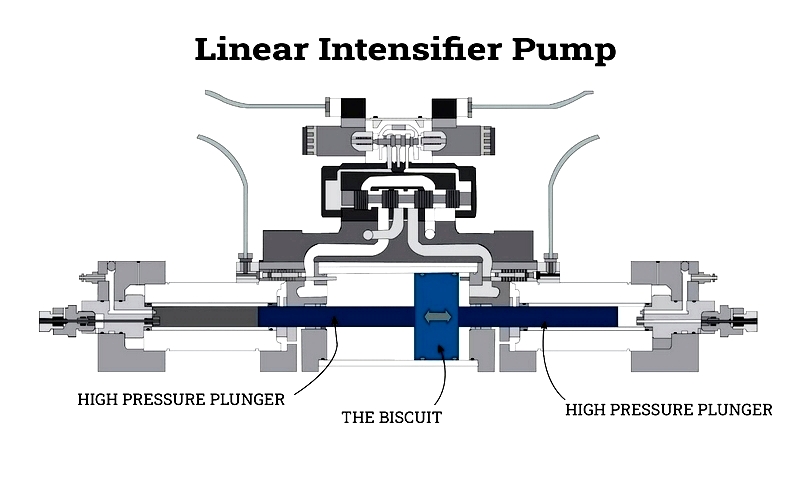

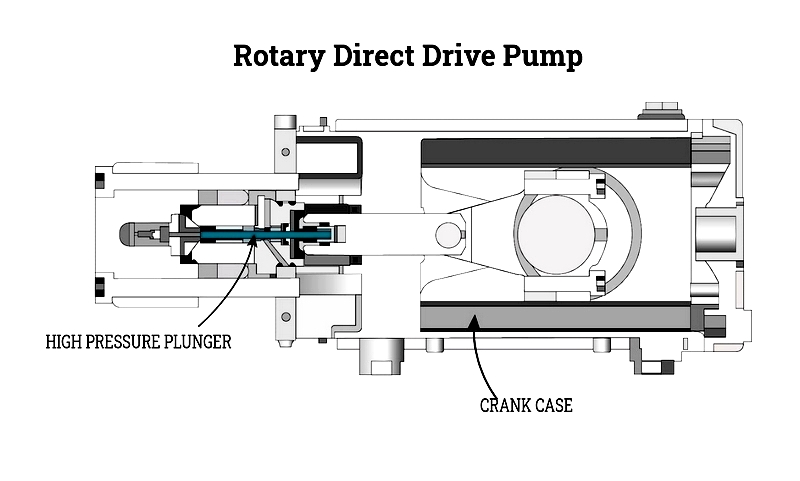

Pressurizing the Water

Industrial pumps, including linear intensifiers and rotary direct drive systems, generate the required water pressure. These incorporate electric motors, filtration systems, and advanced controls for safe operation.

Linear intensifiers use hydraulic oil to amplify pressure, achieving up to 90,000 psi in advanced systems. Rotary direct drive pumps offer lower maintenance alternatives for less demanding applications.

The choice between pump types depends on required pressure, duty cycle, and operational costs.

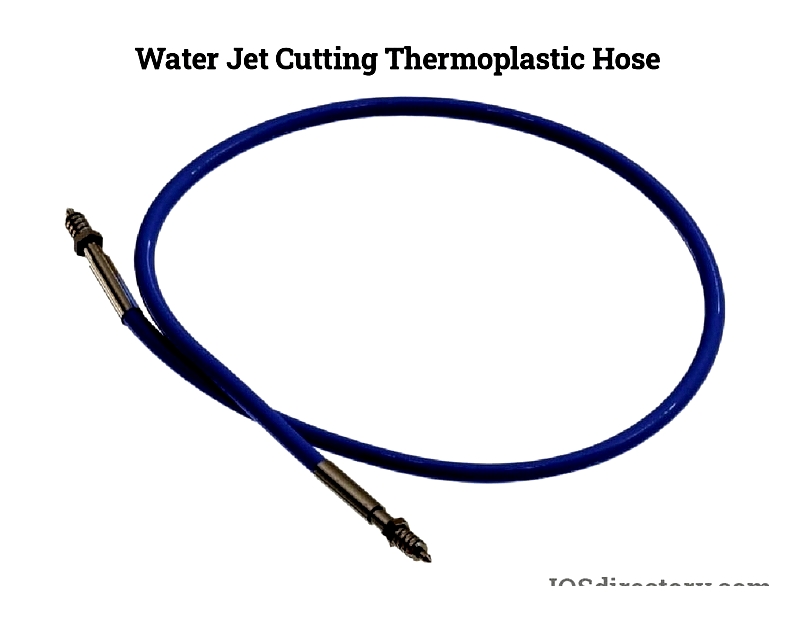

High Pressure Tubing

Specially engineered tubing transports pressurized water from pump to cutting head. Constructed from durable materials with smooth interiors to minimize turbulence, these components require regular inspection in high-production environments.

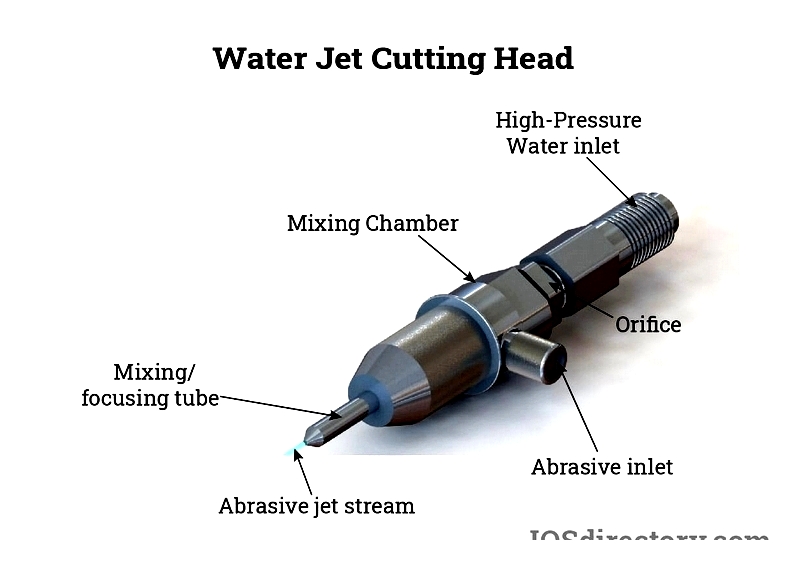

Water Jet Cutting Head

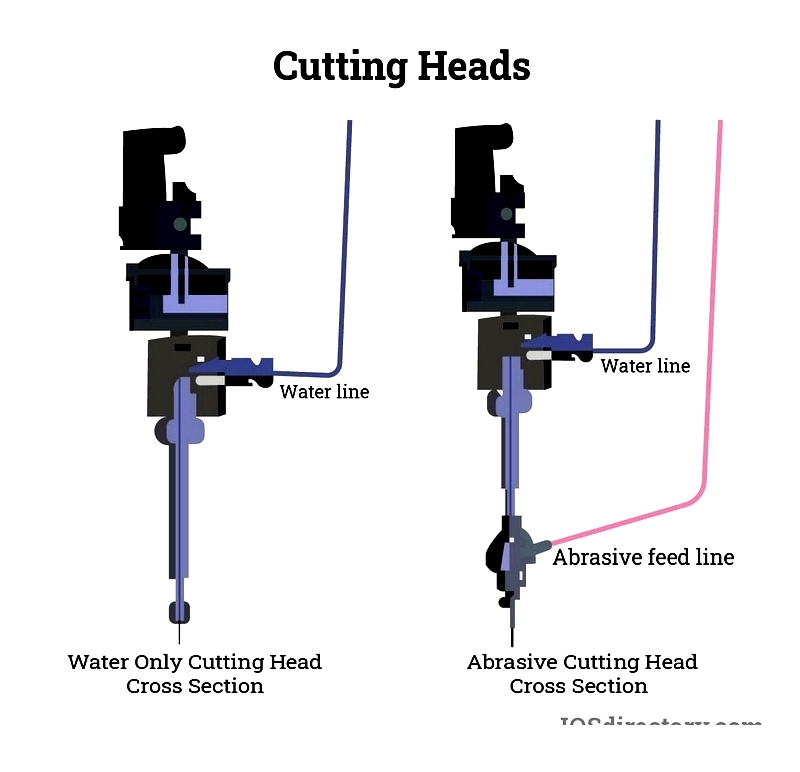

The cutting head features a precision orifice, typically made of diamond or sapphire, where water accelerates to extreme velocities. Head design significantly impacts cutting performance and longevity, with optimized systems lasting 500-1,000 hours.

Different head designs accommodate pure water or abrasive cutting applications, with abrasive systems incorporating a grit delivery tube for enhanced cutting capability.

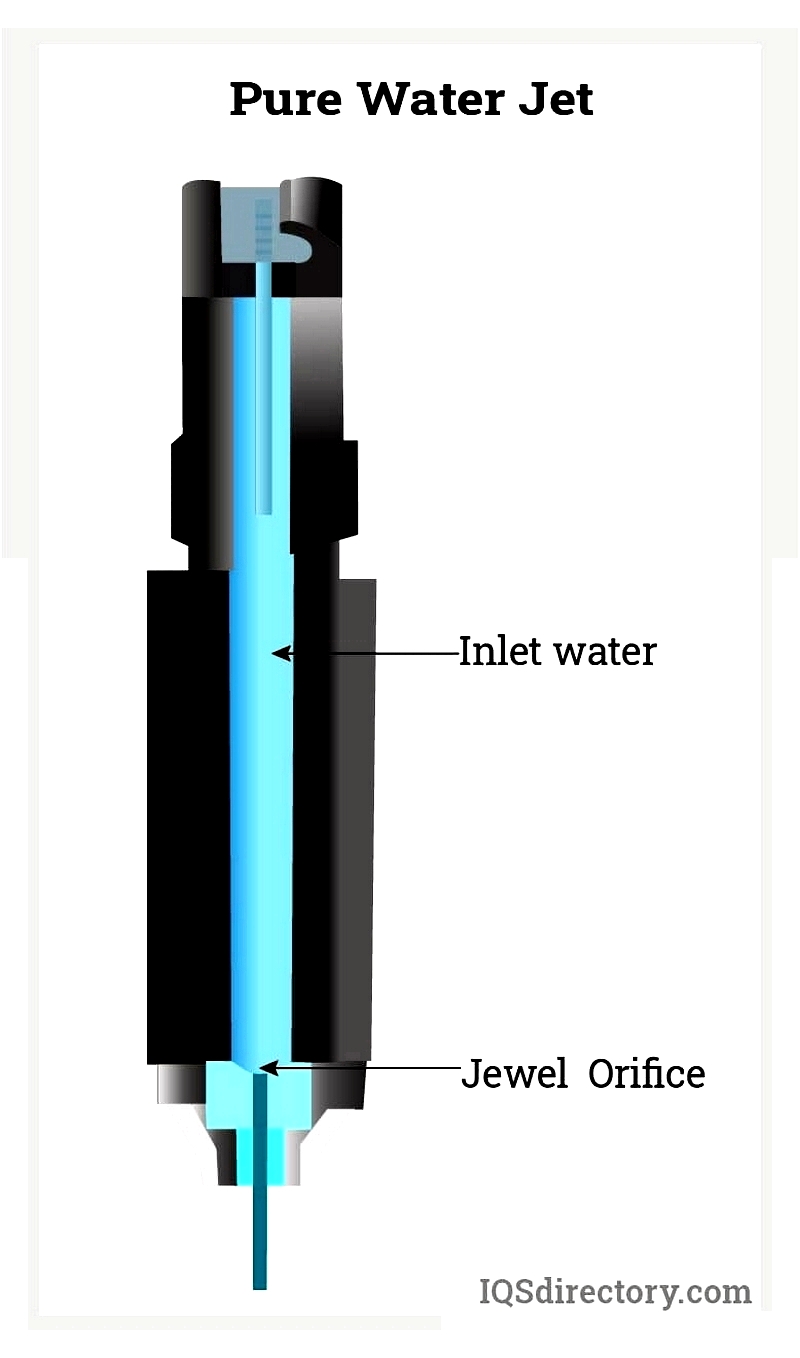

Pure Water Jet Cutters

These original systems remain vital for processing soft materials, offering precise cuts with minimal moisture residue. They employ jewel orifices to create supersonic streams capable of burr-free cutting without thermal effects.

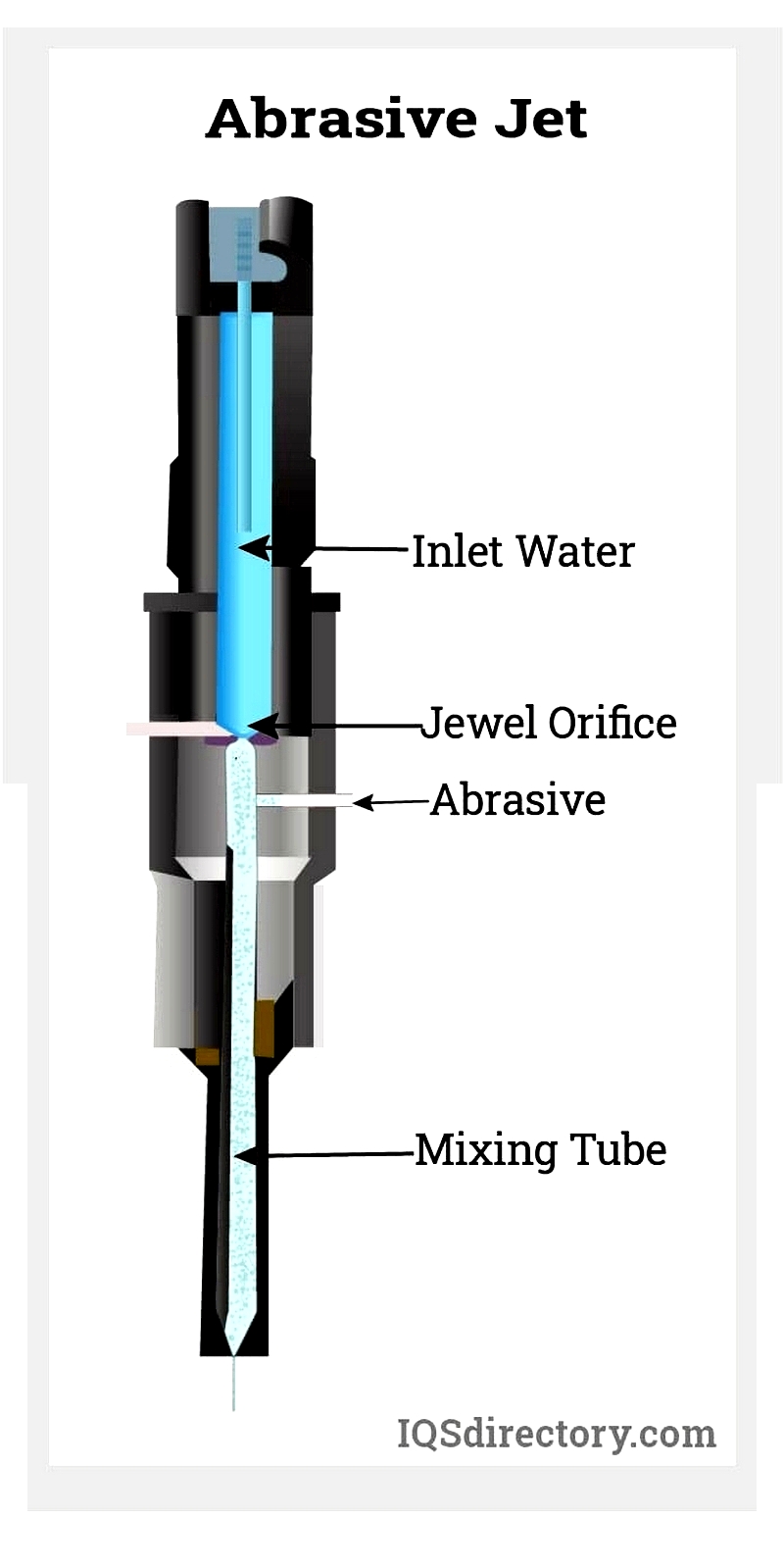

Abrasive Water Jet Cutting System

Abrasive-enhanced systems dramatically expand cutting capabilities, handling materials up to ten inches thick without heat-affected zones. These systems are particularly valuable for metal, stone, and composite processing.

Modern abrasive systems offer significantly greater effectiveness than pure water systems, making them indispensable for precision fabrication across multiple industries.

Advantages of Water Jet Cutting Compared to Other Cutting Methods

Water jet technology offers distinct benefits over alternative processes:

- No Heat-Affected Zone: Preserves material properties during cutting

- Material Versatility: Processes metals, stone, composites, and more

- Precision Capabilities: Achieves tight tolerances for critical components

- Environmental Benefits: Minimizes waste and hazardous byproducts

- Reduced Post-Processing: Produces finished-quality edges

When selecting water jet solutions, consider material requirements, tolerances, production volume, and system capabilities. Partnering with experienced providers ensures access to appropriate technology and expertise.