Introduction

This article provides information and explanations about the cut and sew process.

You'll explore topics including:

- What Cut and Sew Means

- Advantages of Cut and Sew

- Selecting a Cut and Sew Manufacturer

- The Cut and Sew Process

- And More...

Chapter One – Understanding Cut and Sew

The cut and sew method is a manufacturing technique for creating diverse fabric products, from dust covers and tents to guitar cases and foam cushions. This versatility highlights the cut and sew industry's crucial role in fabric goods production and innovation.

The process starts with printing patterns on fabric, which serve as templates for final assembly. Precise cutting according to design and color specifications is essential. Cut and sew involves meticulous steps to ensure fabric items meet exacting quality standards. Each piece receives careful attention and undergoes thorough inspection to satisfy clients, designers, and manufacturers.

This production approach fosters creativity by enabling direct printing on raw fabric, eliminating seam and size limitations. It also offers extensive color options without requiring pre-colored materials.

Cut and sew's adaptability makes it valuable across industries, as most require fabric components in their production. Despite its widespread use, the industry's contribution to product quality and success often goes unrecognized.

Delivering premium products at competitive prices, the cut and sew industry helps clients achieve profitability. It remains fundamental to fabric-based product creation.

Chapter Two – The Cut and Sew Manufacturing Process

Cut and sew manufacturing transforms clothing designs into finished products, offering designers flexibility, quality, and small-batch capabilities. Experienced suppliers assist with fabric sourcing, garment construction, pattern creation, and sample development. These professionals are invaluable for bringing fashion concepts to market.

While accessible to anyone producing apparel, reputable manufacturers implement screening processes to ensure project viability. Though commonly used for fashion items like streetwear and dresses, the method applies to various textile products including home furnishings and accessories.

Typical cut and sew products include hoodies, t-shirts, jackets, dresses, and sportswear. The technique also creates textile art, curtains, toys, bags, and upholstery—essentially any fabric-based item.

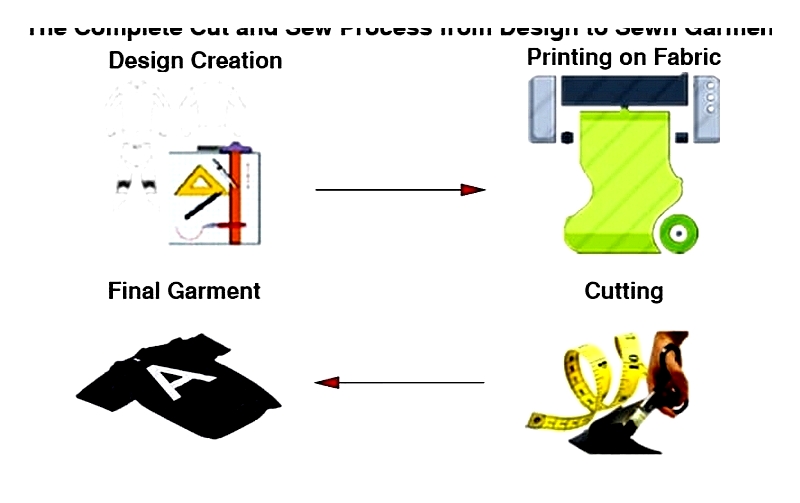

Cut and Sew Process

Pattern Design

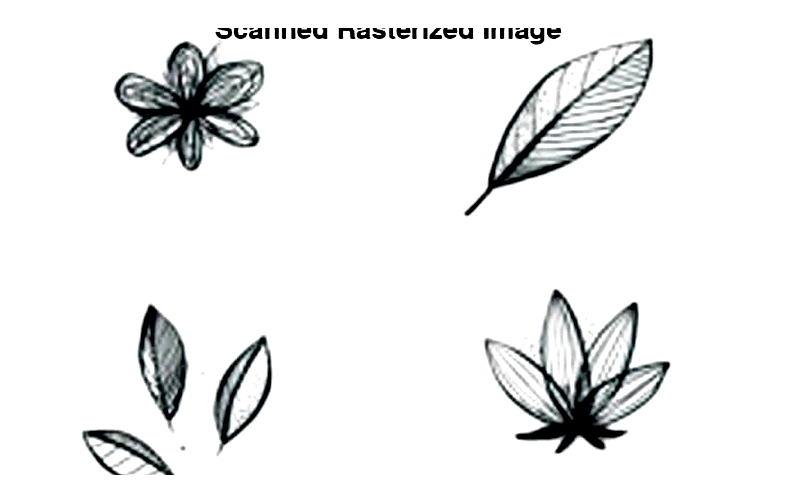

Digital pattern design initiates the manufacturing process, serving as the production blueprint. Designers use software like Photoshop and CAD to create patterns, often starting with hand-drawn sketches scanned at high resolution. Clear, dark lines enhance design clarity.

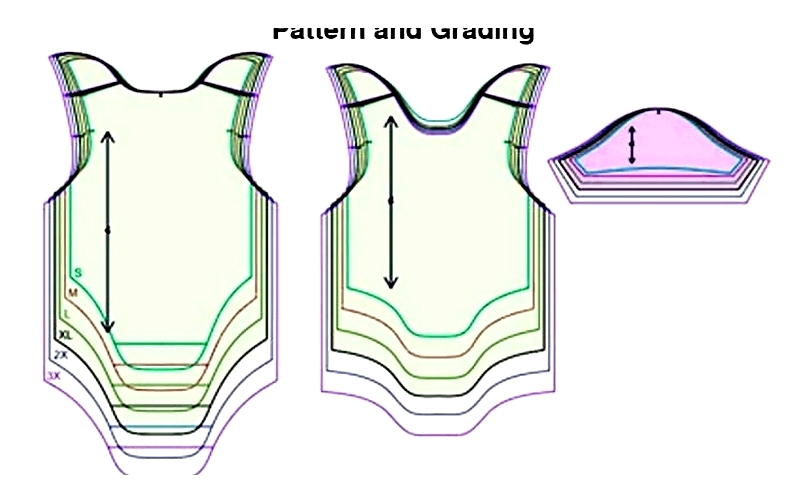

After scanning, images are saved in compatible formats for editing and vector tracing. This ensures patterns match desired fit and style while optimizing fabric use.

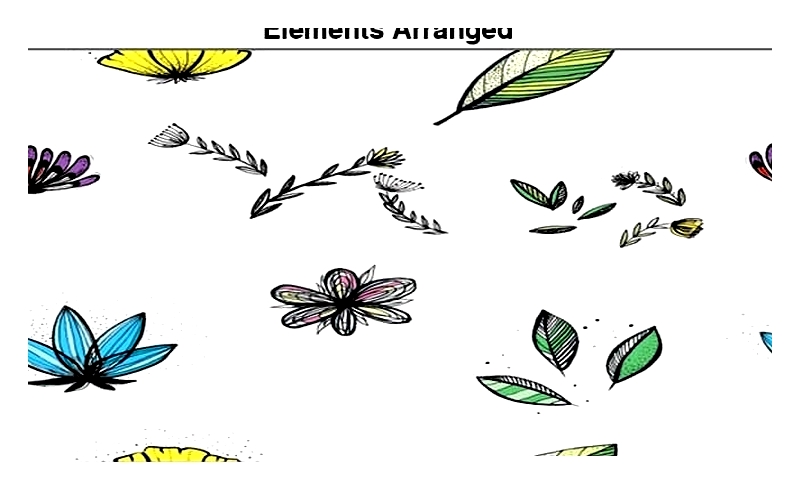

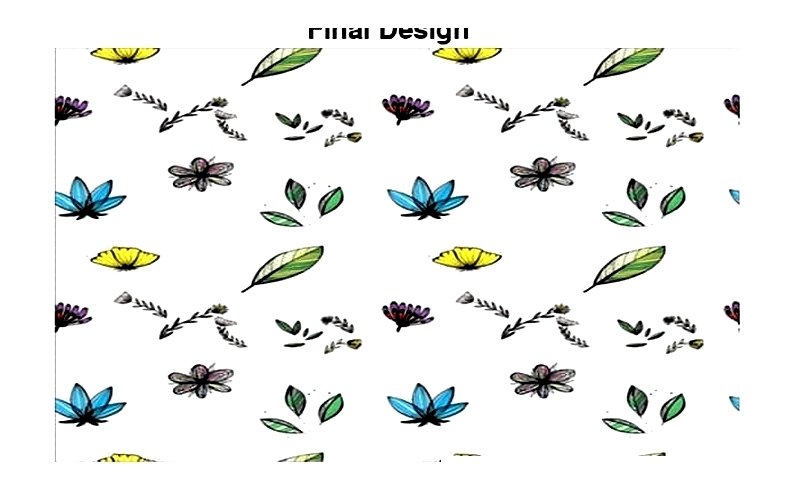

Design elements are separated and layered for color editing and placement. Key graphics are positioned for seamless repeats, crucial for printed garments. Patterns are refined for scale and placement before prototyping.

Final patterns are checked for repeatability and sizing. Files are reviewed against specifications before sampling, ensuring alignment with production requirements.

These steps yield production-ready files for textile printing, forming the foundation for quality apparel manufacturing.

Finding a Sewing Manufacturer

With approved designs, selecting a manufacturer becomes critical for quality, cost, and timing. Reputable facilities offer skilled labor and scalable production capabilities.

Manufacturers place patterns on fabric, cut textiles, and assemble garments per specifications. Many specialize in clothing while others produce accessories and soft goods. The model accommodates low minimum orders, benefiting startups and small brands.

Key production stages include:

- Fabric Inspection – Materials are checked for defects before cutting

- Cutting – Precise cutting using digital patterns

- Sewing – Skilled assembly with attention to construction

- Quality Check – Multiple inspections ensure compliance

Research manufacturers through industry directories and reviews. Consider communication, portfolios, and labor standards. Domestic production offers advantages like responsiveness and quality control.

Manufacturers provide additional services like design consulting and prototyping. Building relationships through samples and factory visits helps ensure successful production.

Offshore

Offshore production attracts brands seeking lower costs for bulk orders. Factories in Asia and elsewhere offer reduced labor expenses but may present communication and quality challenges.

Many brands now prefer domestic manufacturing for consistent quality, faster turnaround, and ethical considerations. The choice depends on brand values, volumes, and target markets.

Digital Printing

Printing methods significantly impact garment quality. Modern digital printing enables vibrant, detailed designs through various techniques:

- Screen Printing – Ideal for simple graphics and high volumes

- Direct to Garment – Suitable for intricate one-off designs

- Digital Printing – Delivers photo-quality patterns on fabric

- Sublimation – Best for synthetic fabrics with vibrant prints

- Direct Digital – Works with natural fabrics for versatile applications

Post-printing treatments enhance color fastness and fabric feel. Proper printing technology ensures standout custom products.

Cutting Process

Precision cutting determines garment fit and material efficiency. The process involves rough and precision cutting stages using manual, semi-automated, or computerized methods.

Computer-aided cutting ensures consistency, reduces waste, and optimizes fabric layout. Strict procedures maintain safety and quality throughout production.

Expert cutting technology delivers the accuracy and repeatability required for quality garment manufacturing and long-term success.