Introduction

This article provides an in-depth exploration of steel service centers.

Continue reading to discover key topics including:

- What a Steel Service Center is

- Benefits of Using a Steel Service Center

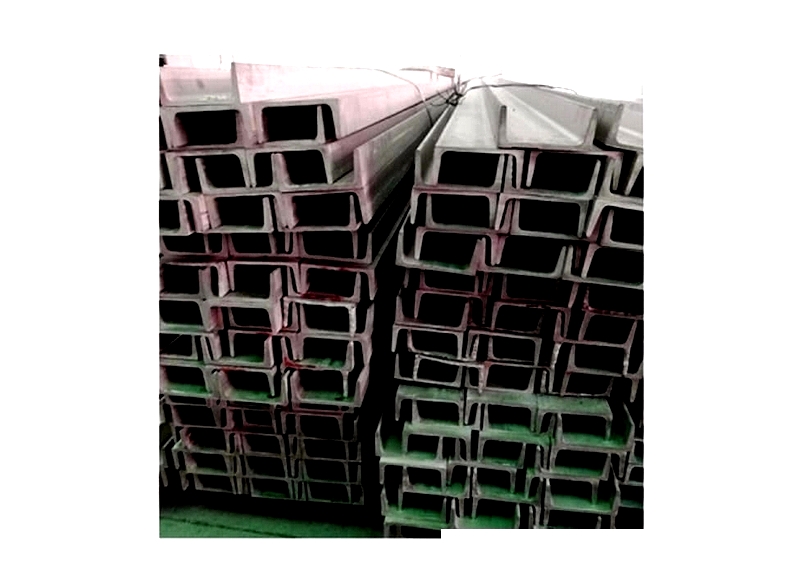

- Products Available at Steel Service Centers

- And More...

Chapter 1: What is a Steel Service Center?

Steel service centers purchase steel directly from mills and manufacturers, then distribute these materials to various clients. They play a crucial role in the steel supply chain by bridging the gap between producers and end-users. This partnership allows clients to focus on their primary business activities. Their customer base spans diverse industries, including automotive, electronics, HVAC, transportation, construction, and home appliances, serving both large corporations and small businesses.

These centers specialize in bulk steel procurement, inventory management, and custom steel product fabrication to meet specific customer requirements. They can also modify steel into desired forms, dimensions, and shapes. Delivery terms, including volume and schedule, are outlined in contracts between service centers and clients, who then utilize these products according to their unique needs.

Chapter 2: Advantages of Using a Steel Service Center

Partnering with a steel service center provides significant benefits for businesses requiring dependable steel supply, value-added processing, and efficient supply chain solutions. By utilizing these specialized services, manufacturers, fabricators, and construction companies can enhance quality control, accelerate production timelines, and scale operations while reducing waste and risk.

Cost Savings and Reduced Procurement Expenses

Steel service center clients enjoy substantial cost advantages through strategic sourcing and distribution:

- Lower minimum order quantities compared to steel mills, making them ideal for small businesses and startups

- Comprehensive warehousing and inventory management for various steel products, allowing precise ordering to minimize storage costs

- Economies of scale from bulk purchasing enable lower per-unit pricing for customers

- Access to value-added services like cutting, bending, and finishing eliminates need for in-house equipment and specialized labor

- Custom-sized products reduce material waste and optimize usage

Quality Assurance and Certification

Service centers maintain direct relationships with top-tier mills and implement rigorous quality control measures, including inspections, testing, and third-party certifications. Many hold ISO 9001 and IATF 16949 certifications, ensuring compliance with industry standards. Complete traceability and mill test reports provide additional assurance.

One-Stop Steel Product Source

Consolidating procurement through a single service center simplifies vendor management. Their extensive inventories of flat-rolled, structural, and tubular steel products support JIT manufacturing and lean supply chain strategies.

Faster Delivery Times

Maintaining ready stock enables service centers to fulfill orders quickly, avoiding the extended lead times associated with direct mill orders. This responsiveness helps manufacturers meet tight deadlines and adapt to project changes.

Enhanced Business Focus

Outsourcing steel procurement and processing allows companies to concentrate on core competencies like product development and customer service, driving innovation and growth. Many centers offer additional supply chain solutions for further optimization.

Selecting the Right Service Center

Key selection criteria include inventory availability, service offerings, certifications, reputation, location, and customization capabilities. Comparing multiple providers ensures access to competitive pricing and advanced fabrication technologies.