Introduction

This article provides comprehensive insights into various aspects of metal shelving, including:

- Construction and Materials of metal Shelving

- Different Types of metal Shelving

- Functional Uses of metal Shelving

- Advantages of metal Shelving

- And More...

Chapter 1: Materials and Construction Techniques for metal Shelving

This chapter explores the fundamental aspects of metal shelving, focusing on its definition, design, and the materials commonly used in production.

Understanding metal Shelving

metal shelving provides organized storage solutions with compartments designed to hold various items, from tools and equipment to books and laboratory chemicals. Its versatility makes it suitable for diverse industrial applications.

metal Shelving Construction Process

The construction of metal shelves typically involves designing and measuring the shelf, acquiring materials, cutting them to size, welding components together, finishing surfaces, and applying protective paint. This process balances cost-effectiveness with adherence to industry standards.

Common Materials in metal Shelving Production

Various materials are used in manufacturing metal shelves, each offering unique properties:

Stainless Steel

Stainless steel is a preferred material for shelving due to its exceptional durability and strength. It's particularly suitable for businesses requiring robust storage solutions.

Its ability to withstand heavy loads and high temperatures makes it ideal for food industry applications. Stainless steel is also easy to clean and resistant to damage, with higher-grade variants offering superior longevity.

As an alloy of iron with elements like carbon and chromium, steel's strength varies with composition. Higher carbon content increases strength, making it valuable across multiple industries.

Key properties of steel include:

High Tensile Strength

Steel can endure significant stress before fracturing, making it highly resistant to breakage.

Ductility

Despite its strength, steel can be reshaped into various forms without breaking, allowing for versatile applications.

Durability

Its hardness makes steel resistant to wear, suitable for demanding environments.

Lustrous Finish

Steel's shiny appearance enhances its aesthetic appeal.

Corrosion Resistance

Stainless steel, with added elements like chromium, offers excellent rust resistance for long-term use.

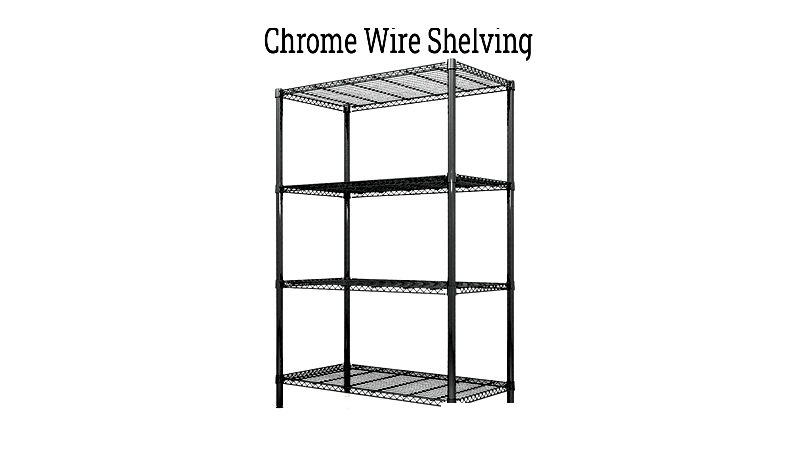

Chrome Wire

Chrome wire shelving features a sleek finish that improves aesthetics while maintaining strength. Its design allows water drainage, aiding fire safety compliance.

The steel gauge determines weight capacity, with lower numbers indicating stronger shelving. Chrome wire shelving is commonly used in offices, retail spaces, and dormitories.

Offering a cost-effective alternative to stainless steel, chrome shelving provides durability and a clean appearance.

Wrought Iron

Wrought iron is valued for its adaptability, durability, and decorative potential. While more expensive, it's an excellent choice for custom storage solutions.

Aluminum

Aluminum combines durability with lightweight properties, offering good conductivity and corrosion resistance.

Epoxy Coated Wire Shelving

Epoxy coating provides additional protection, making these shelves ideal for food-handling areas due to their resistance to bacteria and tarnishing.

Aluminum's notable characteristics include:

Lightweight Nature

Easy to handle while maintaining strength through alloy adjustments.

Corrosion Resistance

Its natural oxide layer protects against environmental damage.

Hygienic Properties

Impermeable and odorless, suitable for laboratory use.

Recyclability

Environmentally friendly with minimal energy required for recycling.

Copper

Copper offers strength, corrosion resistance, and conductivity, making it suitable for specialized applications.

Additional benefits include:

Non-Magnetic Quality

Ideal for storing metal items.

Antibacterial Properties

Helps maintain sanitary conditions.

Chapter 2: Varieties of metal Shelving Systems

Different metal shelving types cater to specific commercial, industrial, and warehouse needs. Selection depends on inventory requirements, application, and available space.

Clip-Style Steel Shelving

This adjustable, durable option features tool-free assembly, making it popular for manufacturing and retail storage.

Ideal for heavy loads with adjustable heights to accommodate various items.

- Best for: Files, hardware, retail goods

- Advantages: Customizable, high capacity, flexible organization

Bulk Rack Shelving

Designed for large items, these systems feature boltless assembly for easy setup in warehouses.

Accommodates oversized inventory with various decking options.

- Best for: Industrial supplies, packaging materials

- Advantages: Easy assembly, wide-span capacity

Rivet Shelving

Combining durability with easy assembly, rivet shelving supports heavy loads in warehouse settings.

Available with particle board or metal wire decking for different environmental needs.

- Best for: High-density storage, automotive parts

- Advantages: Tool-free assembly, customizable heights

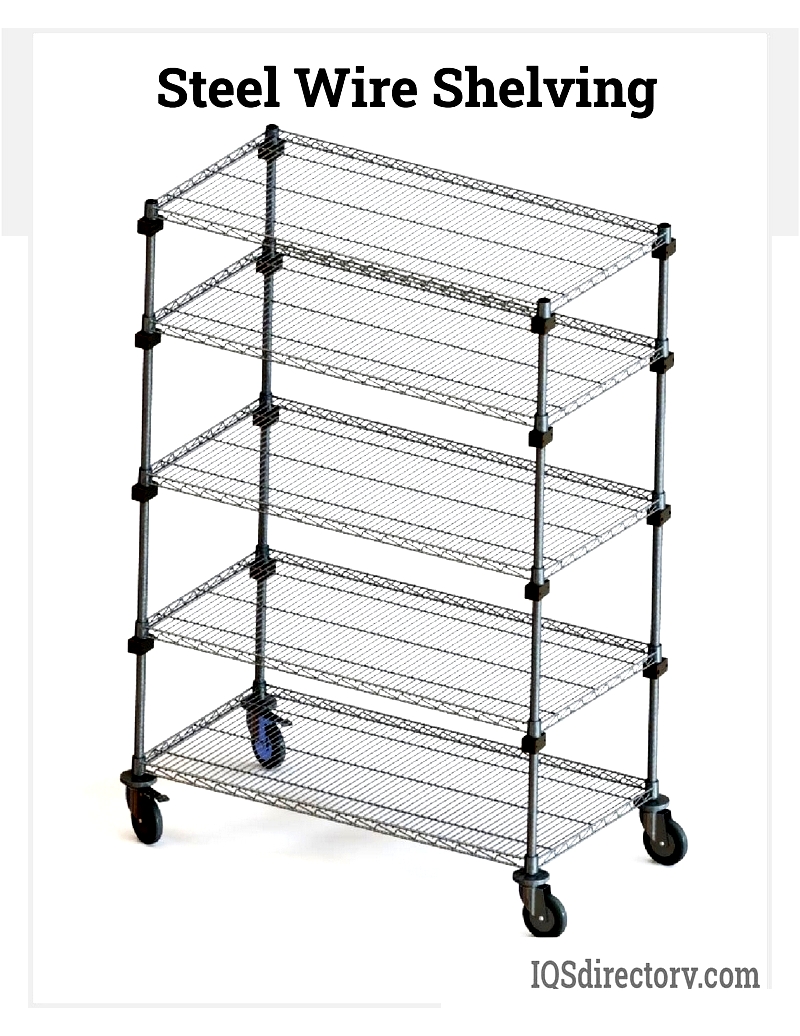

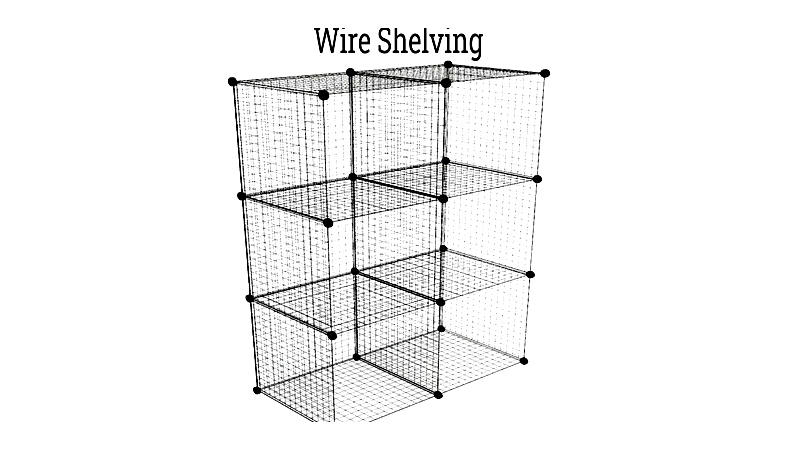

Wire Shelving

Ideal for environments requiring visibility and ventilation, such as food service and healthcare.

Promotes airflow and cleanliness while supporting substantial loads.

- Best for: Food storage, medical supplies

- Advantages: Easy cleaning, modular configurations