Introduction

This article provides a comprehensive overview of stainless steel grades.

You'll discover key information about:

- The definition of stainless steel grades

- Major stainless steel categories

- Common stainless steel grades

- Applications for various stainless steel grades

- And more...

Chapter 1: What Are Stainless Steel Grades?

Stainless steel grades are alloys composed of carbon, iron, chromium (10.5%-30%), nickel, molybdenum, and other elements. This versatile material finds widespread use in manufacturing products, tools, equipment, and infrastructure across industrial, commercial, and residential applications.

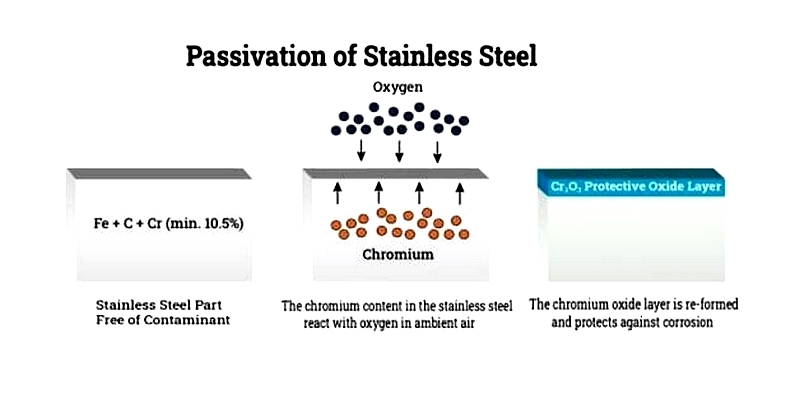

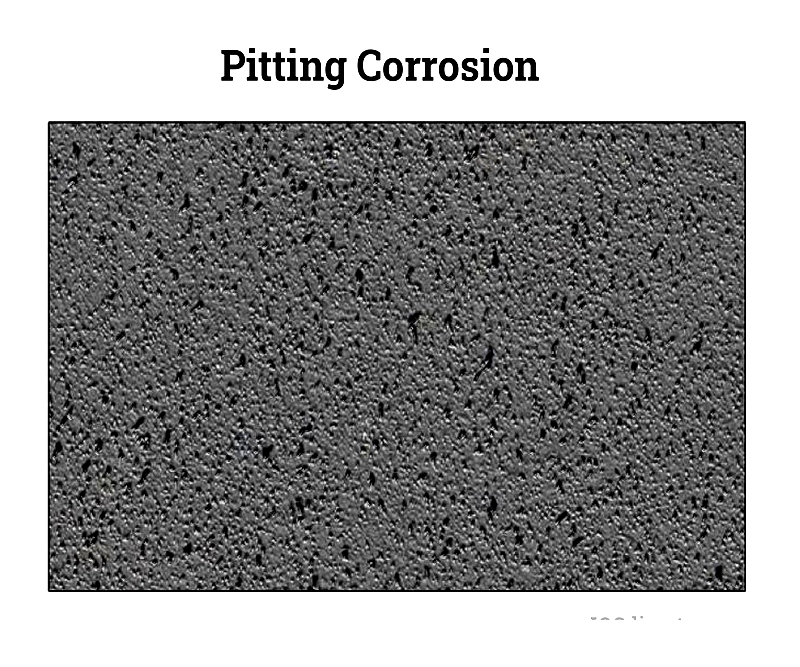

Chromium gives stainless steel its remarkable corrosion resistance by forming a protective chromium oxide layer when exposed to oxygen. Molybdenum further enhances this resistance by preventing pitting. While this layer can self-repair minor damage, prolonged exposure to chlorides, harsh cleaners, salt, humidity, or abrasion may cause rust.

Beyond corrosion resistance, stainless steels offer excellent mechanical properties including strength, toughness, ductility, and fatigue resistance. They withstand extreme temperatures and pressures while maintaining chemical inertness, making them ideal for chemical processing. Their attractive finish also makes them aesthetically appealing.

Chapter 2: Categories of Stainless Steel Grades

Stainless steels are divided into five main categories, each with distinct crystal structures, compositions, and properties. Understanding these categories is essential for selecting the right material for manufacturing, construction, and specialized engineering projects. This chapter details each category's characteristics and applications.

Austenitic Stainless Steels

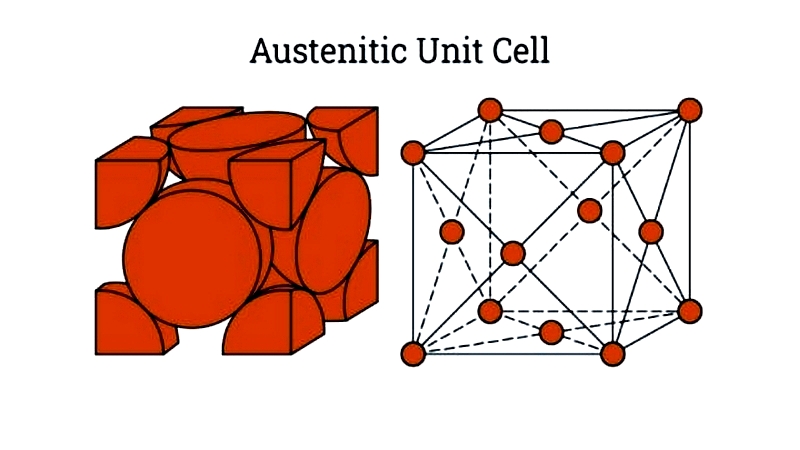

As the most common type, austenitic stainless steels form the industry backbone, including the 200 and 300 series (notably 304 and 316 grades). Their face-centered cubic structure, stabilized by nickel and manganese, remains stable at all temperatures.

These steels contain 8-12% nickel and 16-30% chromium, offering excellent corrosion resistance but at higher cost. While not heat-treatable, they can be cold-worked to improve strength. Their non-magnetic nature, formability, and weldability make them ideal for food processing, medical equipment, and marine applications.

Ferritic Stainless Steels

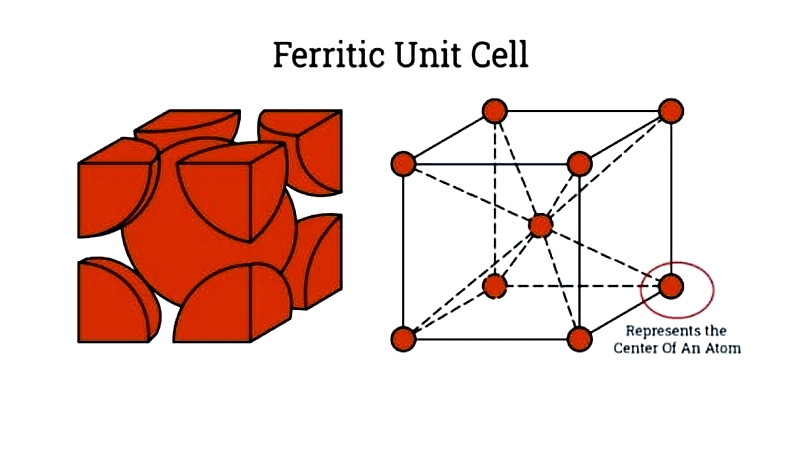

Featuring a body-centered cubic structure, ferritic steels contain 11-27% chromium with minimal nickel. Their low carbon content (0.03%) ensures good ductility but prevents heat treatment hardening.

These magnetic steels offer high thermal conductivity and stress corrosion resistance, making them suitable for automotive exhausts and heat exchangers. Grades like 409 and 430 provide cost-effective solutions for appliances and architectural applications.

Martensitic Stainless Steels

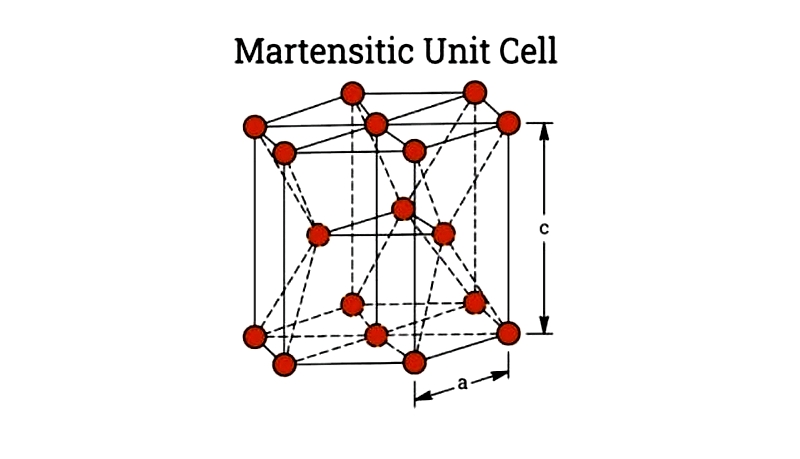

With a body-centered tetragonal structure, these steels contain 11.5-18% chromium and 0.1-1.2% carbon. Their hardness can be increased through heat treatment, but their brittleness complicates welding and forming.

Grades like 410 and 420 are used for surgical tools and cutlery where strength and moderate corrosion resistance are needed. They're classified in the 400 series alongside ferritic steels.

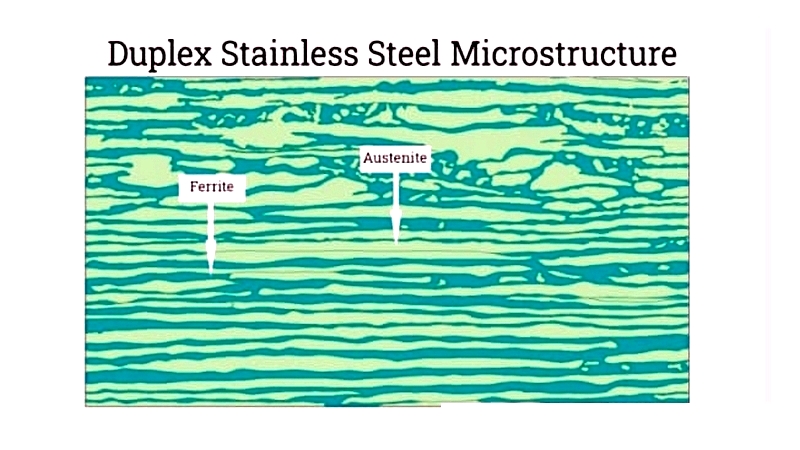

Duplex Stainless Steels

Combining austenitic and ferritic phases, duplex steels offer double the strength of conventional grades. While less ductile than austenitic steels, they provide better stress corrosion resistance and cost efficiency.

Grades like 2205 excel in harsh environments, making them ideal for oil/gas and chemical processing. Their strength-to-weight ratio and durability suit marine and desalination applications.

Precipitation-Hardened Stainless Steels

PH steels gain strength through age hardening, forming intermetallic precipitates. They offer austenitic-level corrosion resistance with enhanced mechanical properties.

The 17-4 PH grade is widely used in aerospace and precision components. When selecting grades, consider corrosion needs, strength requirements, formability, and cost. Consult manufacturers for specific application guidance.