Introduction

This article provides an in-depth exploration of tungsten metal.

Key topics covered include:

- Fundamentals of Tungsten metal

- Varieties of Tungsten Alloys

- Tungsten versus Tungsten Carbide

- Applications and Benefits of Tungsten metal

- And More...

Chapter 1: Understanding Tungsten metal: Principles and Applications

This section explores tungsten metal's various aspects, including its natural occurrence, manufacturing processes, and notable characteristics.

What is Tungsten?

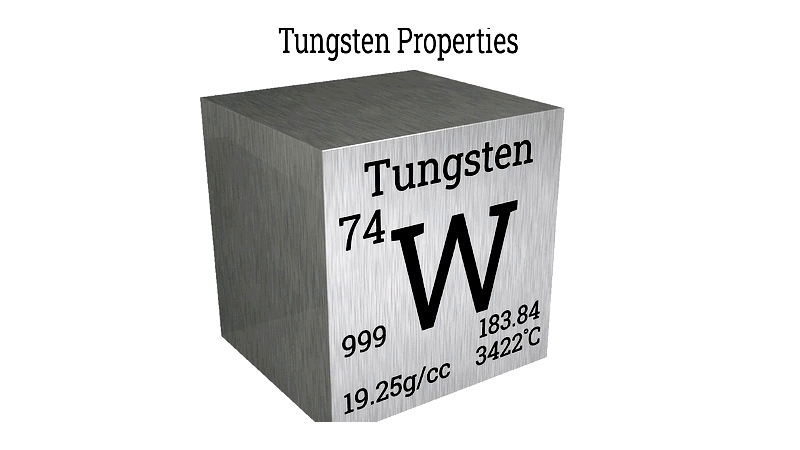

Tungsten is a silvery-gray metal known for its exceptional hardness. It possesses remarkable tensile strength and can endure extreme temperatures, with a melting point of 6,191°F (3,421.7°C) and boiling point of 10,220°F (5,660°C). With atomic number 74, tungsten belongs to the transition metals group in the periodic table.

Occurrence of Tungsten metal

Tungsten occurs naturally in minerals like wolframite and scheelite. Wolframite, an iron-manganese tungstate (FeMn)WO4, forms a solid solution of ferberite (FeWO4) and hubnerite (MnWO4). Scheelite, calcium tungstate (CaWO4), serves as another significant source. Tungsten minerals vary in rarity and economic value, with some being moderately common and others extremely rare.

Tungsten Nomenclature

Below are key terms related to tungsten metal, covering its applications and alloy descriptions.

Alloy Mixture

An alloy combines two or more elements to optimize performance. Notable tungsten alloys include tungsten carbide (tungsten and carbon), Hastelloy (nickel, chrome, molybdenum, and tungsten), and various tungsten-nickel alloys.

Tungsten’s Brittle Nature

Brittleness refers to a material's tendency to fracture under stress. Pure tungsten is prone to cracking, so it's often alloyed with other metals to enhance durability. For example, combining tungsten with carbon significantly improves strength for demanding applications.

Tungsten Filament

A filament is a thin metal wire in bulbs that converts electricity to light while withstanding high temperatures.

Melting Point

The melting point is the temperature at which tungsten becomes liquid, reaching an exceptional 3,422°C (6,192°F).

Superalloy

Superalloys are metals with high tensile strength, corrosion resistance, and elevated melting points.

Tensile Strength

In engineering, tensile strength refers to the maximum stress a metal can endure before deforming or breaking.

Wolfram or Tungsten

The name "wolfram" derives from tungsten's primary ore, wolframite.

Properties of Tungsten

Tungsten exhibits the following properties:

Tungsten Chemical Properties

As a transition metal, tungsten displays multiple oxidation states: +2, +3, +4, +5, and +6. With an atomic number of 74 and relative atomic mass of 183.84, it remains solid at room temperature due to its stable isometric crystal structure. Tungsten resists most acids except nitric and hydrofluoric acids. At high temperatures, it reacts with oxygen to form trioxides. Tungsten consists of five stable isotopes: tungsten-180, -182, -183, -184, and -186.

Tungsten Physical Properties

Pure tungsten is a shiny white metal that's easy to work with, though trace oxygen or carbon can make it brittle under stress. It's the densest engineering material at 19.25 g/cm³, with a melting point of 3,140°C and boiling point of 5,700°C. Tungsten has the lowest vapor pressure among metals and the highest modulus of elasticity (400 GPa). Its thermal expansion coefficient matches borosilicate glass, making it ideal for glass-metal seals.

Tungsten Attributes

Tungsten exhibits conventional metallic properties, efficiently conducting electricity and heat. Its corrosion resistance makes it unique, though pure tungsten's brittleness often necessitates alloying for improved strength and workability.

Producing Tungsten metal

Tungsten undergoes multi-stage extraction and refining. Ore is first converted to tungsten (VI) oxide (WO3), then reduced to powder using hydrogen or carbon. Due to its high melting point, forming ingots is impractical. Powder is mixed with nickel or other metals before sintering. Tungsten hexafluoride (WF6) can also be reduced with hydrogen:

WF6 + 3H2 → W + 6HF

Sintered alloys are processed into billets, then shaped into foils, bars, plates, or sheets. Tungsten products come in black (lubricated), oxide, or cleaned forms, with further refinement using diamond or silicon carbide tools.

Tungsten Products

Tungsten is used in electrodes, drilling equipment, light bulbs, industrial machinery, military armament, coatings, X-ray screens, and construction tools. Alloys are vital for heat sinks, turbine blades, and heavy-duty equipment like weights. Tungsten's corrosion resistance extends tool life, and it's essential for welding equipment, electrical discharge machines, and gas arc welding setups.

Chapter 2: Types of Tungsten Alloys

Tungsten has five main alloy forms: alloyed tungsten, cemented carbide, tungsten carbide, tungsten-based chemicals, and pure tungsten. These are classified by tungsten content and tensile strength, each offering unique mechanical, chemical, and physical properties for industrial applications.

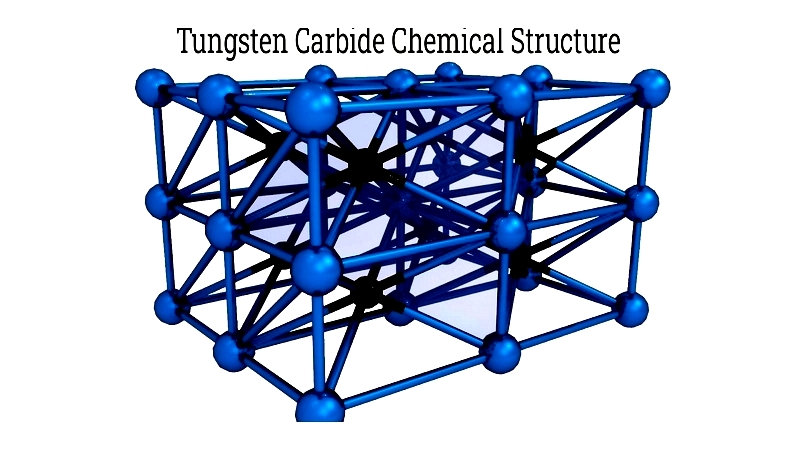

Tungsten Carbide

Tungsten carbide combines tungsten and carbon in near-equal proportions, initially as a fine gray powder. Renowned for hardness, wear resistance, and durability, it withstands harsh chemicals, oxidation, and water. With hardness twice that of high-grade steel and greater density than titanium or steel, tungsten carbide sets industry standards. Over 20 powder grades exist, varying in grain size, tensile strength, hardness, and melting points.

Manufacturing involves sintering and pressing techniques, creating durable products for mining, oil/gas drilling, construction, and metalworking. about 60% of tungsten carbide serves these industries. It's crucial for cutting tools like saw blades, drill bits, and CNC machining implements, offering superior durability and edge retention.

Tungsten carbide resists corrosion from acids, alkalis, oxidation, and water. Its versatility makes it ideal for aerospace, wood processing, and advanced manufacturing. High compressive strength, low thermal expansion, and extreme hardness ensure stability in abrasive environments.

Manufacture of Tungsten Carbide

Tungsten carbide forms by reacting tungsten with carbon at 1,