Introduction

This article covers everything you need to know about RTD sensors.

You'll learn about various topics including:

- What is an RTD sensor?

- Different types of RTD sensor elements

- How RTD sensors work

- Varieties of RTD sensors

- And more...

Chapter One: What is an RTD Sensor?

A Resistance Temperature Detector (RTD) is a passive temperature measurement device that works on the principle of metal resistance changing with temperature. Electrical current passing through the sensor's element generates a resistance value, which is measured by connected equipment. This equipment converts the resistance reading into a temperature value based on the RTD sensor's specific resistance characteristics.

When metal temperature rises, its electrical resistance increases proportionally. RTD sensors measure temperature by detecting this predictable resistance change. These sensors are valued for their accuracy, reliability, and long-term stability in temperature measurement applications.

Chapter Two: Types of RTD Sensor Elements

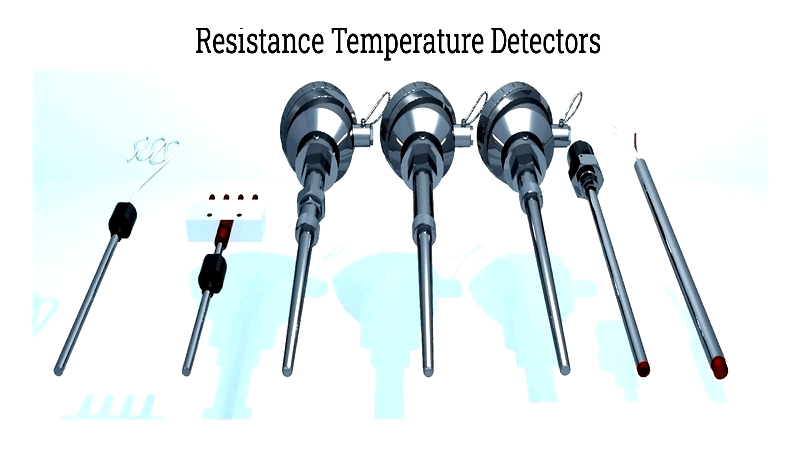

RTD sensors are precision temperature measurement devices widely used in industrial manufacturing, process control, and scientific research. They come in various element types, each designed to meet specific international standards like IEC 60751 and ASTM E1137, and operate effectively across different temperature ranges. Available configurations include thin-film, wire-wound, and coil elements, varying in size, tolerance, and accuracy grade. All RTD elements work by measuring temperature through predictable resistance changes in their metal components.

The resistance element is the core component of an RTD sensor, but requires protection for accuracy and durability in harsh conditions. RTD probes are typically encased in stainless steel or ceramic sheaths. Resistance is measured in Ohms (Ω), with the resistance-temperature relationship being crucial for sensor design and calibration.

Various metals serve as RTD elements. Platinum is the most common and standardized material, especially for high-accuracy applications. Alternatives like copper, nickel, tungsten, and Balco alloy are chosen for specific uses, each offering different sensitivity, range, and cost benefits.

The sensing element's stable resistance change with temperature is fundamental to RTD operation. metal selection significantly impacts measurement precision, response time, and operating range. Below we examine the main RTD element types and their applications.

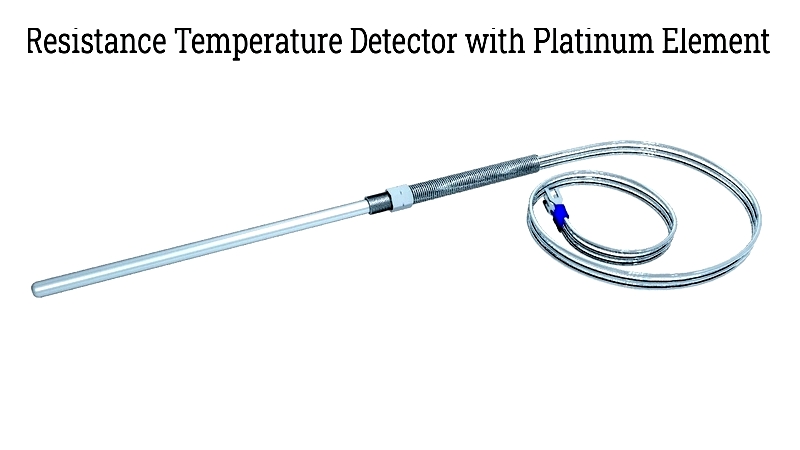

Platinum

Platinum RTD elements use high-purity platinum wire or thin-film technology with a linear, positive temperature coefficient. Known for stability and accuracy, they're the industry standard for industrial temperature measurement. Common variants include 100 Ω at 0°C (Pt100) and Pt1000. Platinum's corrosion resistance and compliance with standards make it ideal for demanding environments like chemical processing and power generation. These sensors work from −200°C to 850°C and can use 2-wire, 3-wire, or 4-wire configurations.

Nickel

Nickel RTD elements balance cost and performance for general-purpose applications. They offer higher sensitivity than platinum but become non-linear above 300°C. Their effective range is −80°C to 260°C, suitable for medium-temperature industrial uses and HVAC controls. However, they show more drift than platinum over time.

Copper

Copper RTDs provide excellent linearity, making them ideal for temperature compensation in electrical equipment. Limited to temperatures below 150°C due to oxidation, they're commonly used in laboratory calibration and equipment monitoring. While cost-effective, they're more prone to drift than platinum.

Copper RTDs offer affordability and good mechanical properties, performing best in protected environments to prevent oxidation.

The following table compares copper, nickel, and platinum elements in terms of range, linearity, stability, and resistance ratios, helping engineers select the right type for their needs.

Balco

Balco RTD elements use a 70% nickel/30% iron alloy with linear resistance response in moderate ranges. The 500 ohm version is popular in HVAC and medical applications, working from −40°C to 116°C. Balco offers cost-effective performance with good stability and linearity.