Introduction

This article covers everything you should know about Platform Industrial Scales.

Continue reading to learn more about:

- What are Platform Scales?

- How Platform Scales Function

- Different Types of Platform Scales

- Key Considerations for Platform Scales

- And much more...

Chapter 1: Understanding Platform Scales

A platform scale is a weighing device featuring one or two metal plates that support items during weighing. These plates may have either diamond-patterned or smooth surfaces. Designed for heavy-duty use, platform scales come in various sizes, capacities, and models to suit diverse industrial requirements.

With their low-profile design, platform scales can accommodate large items like pallets, animals, heavy loads, or individual crates and boxes. Objects are weighed by placing them directly on the scale's surface.

The platform's primary function is to transfer an item's weight to an internal measurement system while providing stable support during weighing. Additional devices can be incorporated to enhance measurement capabilities. Available in multiple designs and load capacities, platform scales are built to meet various user needs.

Platform scales find applications across numerous environments. They're widely used in trading, manufacturing, logistics, and service industries for weight measurement and verification. In sectors requiring precise weighing, these scales play a vital role in revenue generation, safety assurance, and quality maintenance. Beyond commercial uses, they're also suitable for personal, medical, and laboratory applications.

Chapter 2: Platform Scale Mechanics

Understanding platform scale operation is crucial for accurate industrial weighing. The principle is simple: place an object on the platform, and the scale measures its weight. The object's mass creates downward force, which the scale's internal mechanism converts into a readable measurement displayed digitally or analogically. These scales provide precise measurements for industrial, shipping, laboratory, and medical applications.

There are two primary platform scale types: electronic and mechanical. Mechanical scales use levers and springs, while electronic models employ load cells and digital sensors for instant readings. Electronic scales often include features like data logging and system integration, making them ideal for industries requiring fast, traceable weighing processes.

Load Cells

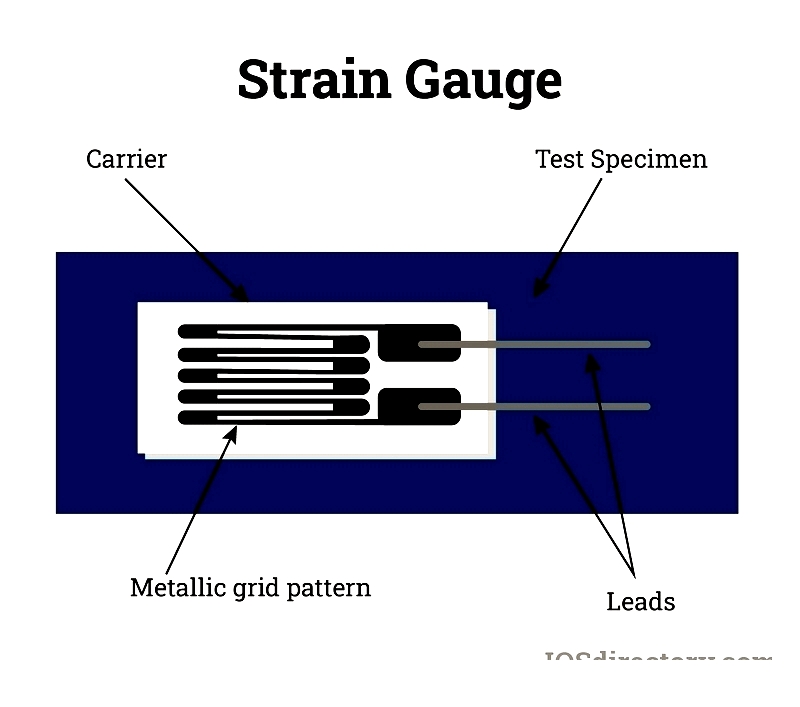

Load cells are essential components in modern weighing systems, acting as the core of electronic platform scales. These transducers convert mechanical force into electrical signals. Most platform scales use strain gauge load cells, which detect deformation from applied loads to measure weight accurately.

Load cell selection depends on capacity needs, environmental conditions, platform size, and specific applications. For instance, shear beam load cells work well in industrial settings, while single point load cells suit bench scales.

Common load cell applications include inventory management, quality control, and product inspection. Advanced load cell technology ensures quick, repeatable measurements that improve operational efficiency.

Strain gauge load cells are the most prevalent in industrial scales. They measure deformation caused by loading, converting mechanical forces into electrical signals for digital display and system integration.

Strain Gauge Load Cells

These load cells contain strain gauge assemblies that detect minute deformations. As current passes through, resistance changes create voltage fluctuations interpreted as weight measurements.

Different strain gauge load cell types serve various weighing needs:

- Single point load cells - Perfect for bench and retail scales requiring balanced loading

- Planar beam load cells - Suitable for compact scales and laboratory use

- Shear beam load cells - Designed for floor scales and heavy-capacity platforms

- S-type load cells - Used in tension testing and specialty processes

Shear Beam Load Cell

A shear beam load cell uses a solid metal element that deforms under force. Strain gauges measure this deformation, converting it into precise electrical signals. These cells handle medium loads up to five tons and are ideal for industrial weighing solutions requiring durability.

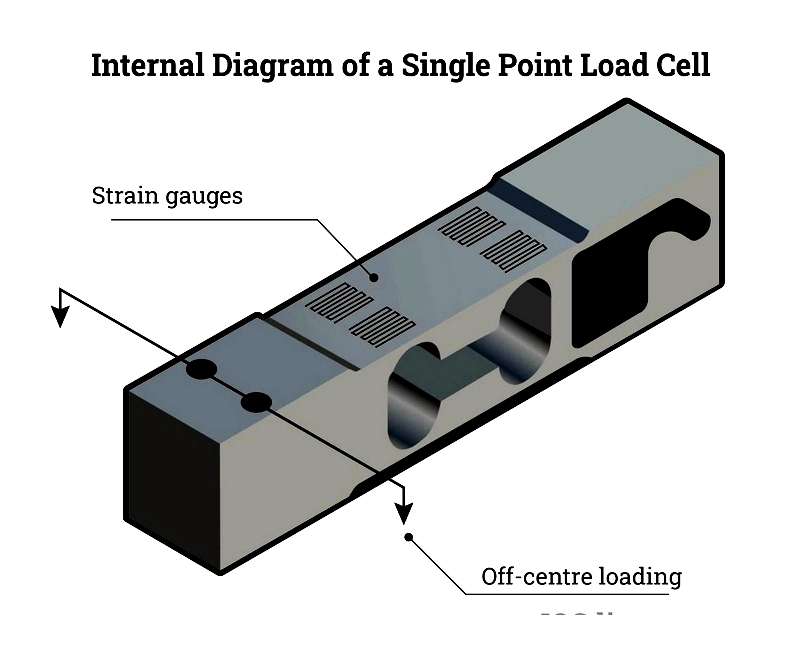

Single Point Load Cell

Single point load cells feature a machined aperture that controls metal thickness for predictable deformation. They maintain accuracy even with off-center loads, making them ideal for bench scales and retail applications.

Magnetic Force Restoration (MFR)

MFR scales offer the highest precision in electronic weighing. Using electrodynamic force compensation, they create counterbalancing electromagnetic forces for ultra-precise measurements. While expensive, they're essential for laboratories and pharmaceutical research.

MFR scales differ from strain gauge systems by maintaining equilibrium through electromagnetic forces. This allows for extremely accurate measurement of small mass changes.

The system processes voltage through high-resolution converters and microprocessors, delivering precise digital readouts. Features like automatic calibration and temperature compensation ensure accuracy in demanding environments.

MFR technology is preferred for critical weighing tasks where minute deviations matter, such as pharmaceutical preparation and chemical analysis.