Introduction

This website provides the most comprehensive information about central vacuum systems available online.

You will discover:

- What a Central Vacuum System is

- The benefits of Central Vacuum Systems

- How Central Vacuum Systems operate

- Installation methods for Central Vacuum Systems

- And much more...

Chapter One – Understanding Central Vacuum Systems

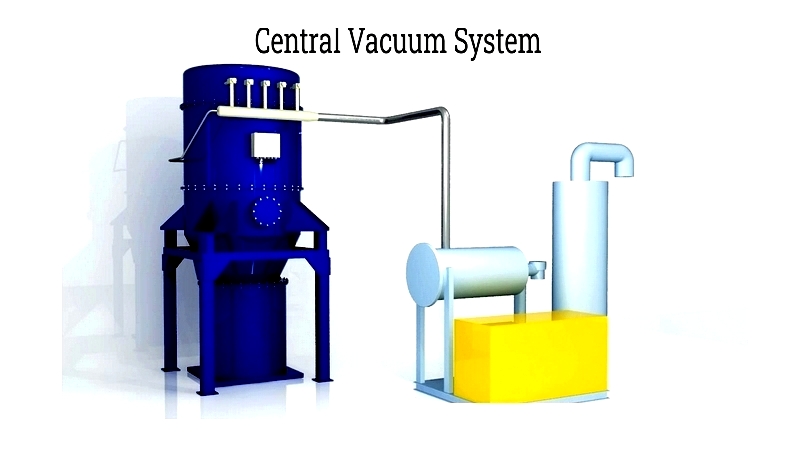

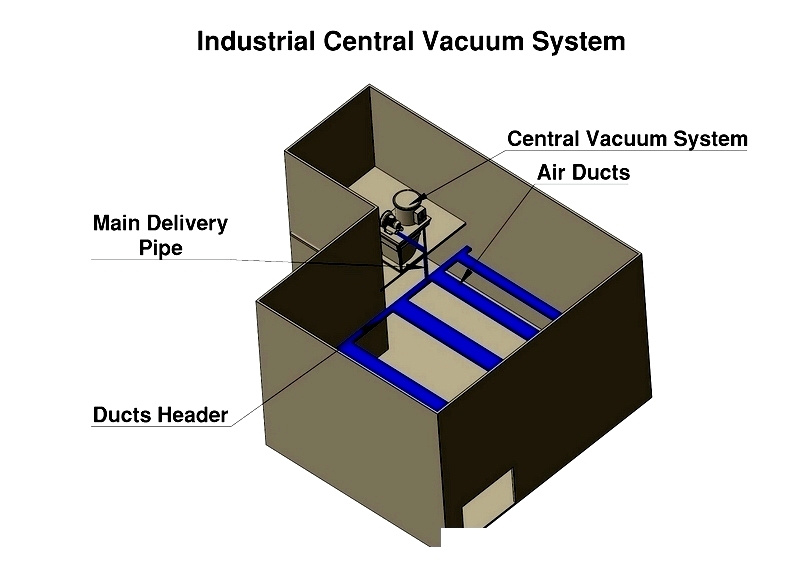

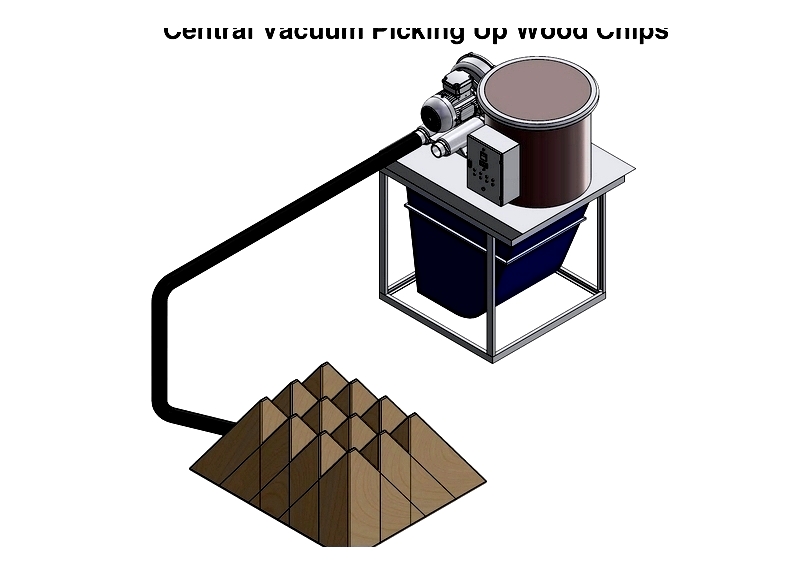

Central vacuum systems are built into a building's infrastructure, featuring connection points in various rooms and hallways. Architects and designers prefer these systems for their convenience, user-friendliness, and minimal maintenance requirements. A central motor generates powerful suction that can remove diverse debris types, from dust and dirt to metal shavings and plastic particles. Depending on design and material handling needs, these systems may include filtration or operate without it.

The system's inlets connect through wall-installed ductwork, piping, or tubing. Maintenance crews use hoses (typically 25-30 feet long) with wands for cleaning. A switch at the vacuum port activates the hose's electrical circuit when the cover lifts.

These systems provide practical, cost-efficient cleaning solutions for large, multi-level buildings. Unlike compact vacuums, they allow multiple users across different floors to access a unified cleaning network. Debris travels through pipes to a collection unit, which may be a removable container or large vacuum bag. Filter-equipped systems position filters to capture airborne particles. Standardized hoses and attachments minimize equipment management for cleaning staff.

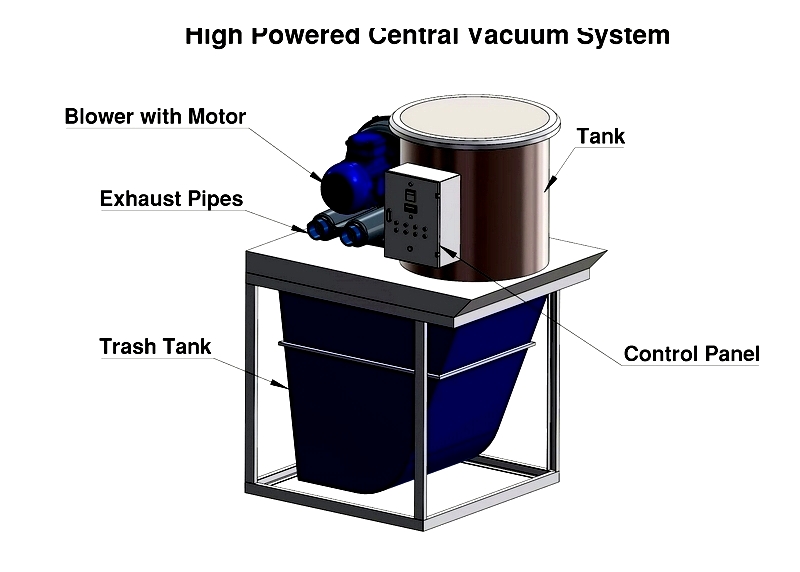

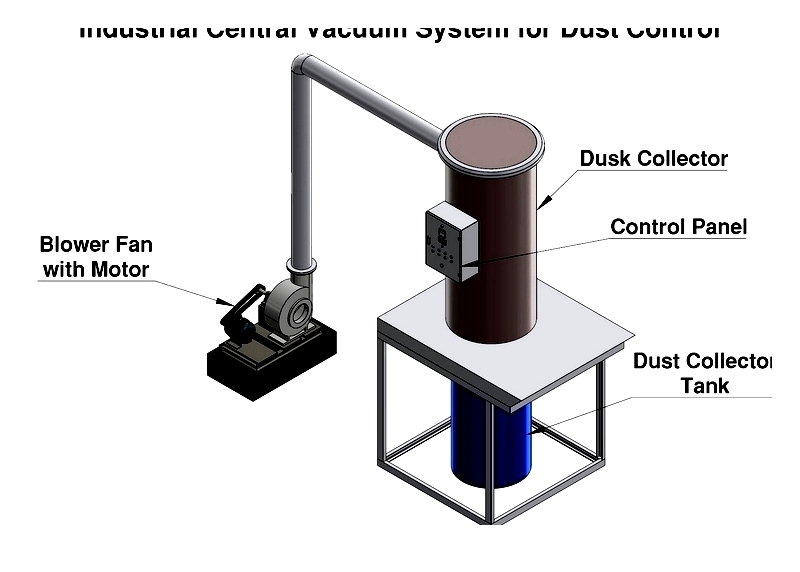

Central vacuum motors operate similarly to standard vacuums but feature larger size, greater power, and enhanced durability. Three primary motor types exist: flow-through, peripheral bypass, and tangential.

Chapter Two – Benefits of Central Vacuum Systems

Central vacuum systems (also called built-in or whole-house vacuums) offer effective, long-term cleaning solutions for residential, commercial, and industrial needs. Unlike portable vacuums requiring frequent handling and emptying, these systems channel collected debris to a central unit, preventing redistribution of dust and allergens while improving indoor air quality.

Key components include a powerful motor, durable canister, efficient filtration (like HEPA filters), and exhaust system. Performance depends on motor specifications (measured in air watts, CFM, or suction power), filtration quality, and proper pipe/inlet installation. Professional installation ensures optimal suction distribution throughout the property.

Central vacuum systems outperform portable and upright vacuums with numerous advantages, making them ideal for homeowners, facility managers, and cleaning professionals seeking efficient dust control and better hygiene.

Central Vacuum System Benefits

Improved Air Quality

Remote operation prevents recirculation of forced air containing dust and allergens. EPA studies show these systems can significantly reduce allergy symptoms by venting exhaust air outside or to utility areas. This creates healthier environments, especially beneficial for those with asthma or respiratory sensitivities.

Enhanced Suction Power

Larger motors deliver superior cleaning performance, removing embedded dust mites, pet dander, and debris from various surfaces. Some models feature dual-motor designs for exceptional suction, ideal for high-traffic areas or pet households, significantly reducing cleaning time.

Advanced Filtration

Multi-stage filters and cyclonic separation effectively capture microscopic particles, reducing dust recirculation. HEPA options provide superior air purification, particularly valuable in medical facilities, labs, or homes with children and pets.

Effective Debris Handling

These systems handle challenging materials like plaster dust, metal shavings, sawdust, and pet hair. Wet-dry models can manage liquid spills, though hazardous substances require specialized industrial vacuums.

Quiet Operation

Remote motor placement (in basements or garages) minimizes noise in living/working areas, ideal for homes with sleeping children or multi-unit buildings.

User Convenience

Lightweight hoses and versatile attachments simplify cleaning various surfaces. Retractable hose systems and strategic inlet placement enhance efficiency for residential and commercial users.

Reduced Maintenance

Large-capacity collection units need emptying only 2-3 times annually, unlike frequent emptying required for portable vacuums.

Long-Term Value

While initial costs are higher, these systems offer low ongoing expenses and 30-40 year lifespans, proving cost-effective versus frequent portable vacuum replacements.

Accessory Compatibility

Standard 1 1/4-inch hoses work with most cleaning tools, from turbo brushes to pet grooming attachments. Some delicate surfaces may require suction regulators.

Property Protection

Eliminating bulky portable vacuums reduces wall/floor damage risks. Operators maneuver only lightweight wands in cleaning areas.

Exceptional Durability

Robust construction ensures decades of reliable service with simple maintenance like filter changes and motor lubrication.

Frequently Asked Questions

Can existing homes accommodate central vacuum systems?

Yes, professionals can retrofit most homes with minimal disruption through proper planning and installation.

Do these systems increase home value?

Yes, they're considered premium features that appeal to health-conscious buyers.

What surfaces can they clean?

All common surfaces including carpets, hard floors, upholstery, and vehicles with appropriate attachments.