Introduction

Here's everything you need to know about portable workbenches.

You'll learn about:

- What a Portable Workbench is

- Different Types of Portable Workbenches

- How Portable Workbenches are Made

- Common Uses for Portable Workbenches

- And much more…

Chapter One - What is a Portable Workbench?

A portable workbench is a versatile, mobile work platform designed for various environments, perfect for preparation, assembly, or repair tasks across industrial and commercial settings. It typically features a flat, smooth surface with multiple attachments to improve organization and productivity.

Portable workbenches mainly fall into two categories: wheeled models and foldable/collapsible designs. Wheeled workbenches provide excellent mobility for easy relocation, while foldable models combine the sturdiness of fixed workbenches with the convenience of hinges and removable parts for compact storage and transport.

Chapter Two - Types of Portable Workbenches

Unlike stationary workbenches designed for specific functions like setup, repair, or testing, portable workbenches adapt to multiple applications. They offer flexible solutions for professionals and hobbyists who need mobile workspaces that can be quickly set up and transported.

The practicality of portable workbenches—whether collapsible, folding, or wheel-mounted—depends on their durability and stability. Key factors include weight capacity, frame strength, and work surface steadiness, which determine suitability for heavy-duty industrial tasks or lighter DIY projects. Choosing the right model depends on your needs, desired portability, and features like storage, tool organization, and adjustable height.

Types of Portable Workbenches

While many imagine foldable workbenches that fit in trucks, industrial models with advanced features support complex manufacturing, assembly, and electronics tasks. These versatile workbenches suit various applications, from industrial machinery repair to delicate electronics assembly, improving productivity and safety in any environment.

Ergonomic

Ergonomic workbenches adjust to workers' body types, preventing injuries and absenteeism. The featured model includes a crank-operated height adjustment system with wide supports for stability. Common in electronics assembly and labs, these workbenches often feature anti-fatigue mats, tiltable surfaces, and modular accessories.

Folding Workbench

Ideal for space-limited areas, folding workbenches collapse for easy storage with removable braces for extra support. Available in various sizes with reinforced legs, they serve as versatile surfaces for contractors, woodworkers, and DIYers at job sites or home garages.

On Wheels with Shelves

These cart-like workbenches feature shelves and durable wheels (some supporting 1000 lbs). Typically with three adjustable shelves, they're ideal for transporting tools and materials in factories, warehouses, and auto shops.

Shelves and Drawers on Wheels

Combining shelves with drawers, these mobile units keep tools organized and accessible. Heavy-duty drawers support substantial weights, while shelves may be solid or perforated for versatility—perfect for mechanics and technicians needing secure tool storage across multiple locations.

Cabinet

Cabinet-style workbenches offer immediate tool access with various drawer sizes, shelves, and locking options. Made from durable steel with secure multi-point locks, they're essential for repair shops and electronics work, providing organized mobile workspaces.

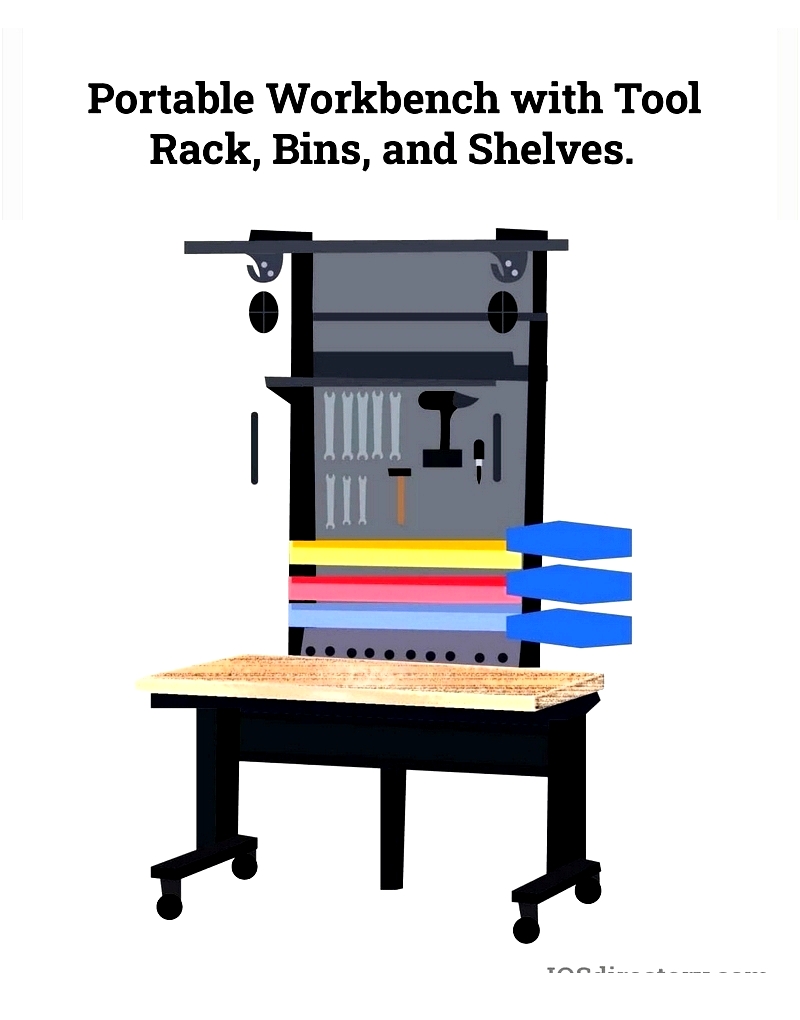

Workbench with Tool Rack

Featuring pegboards or magnetic strips, these workbenches keep tools within reach. Ideal for craftsmen and electricians, they combine mobility with comprehensive tool organization.

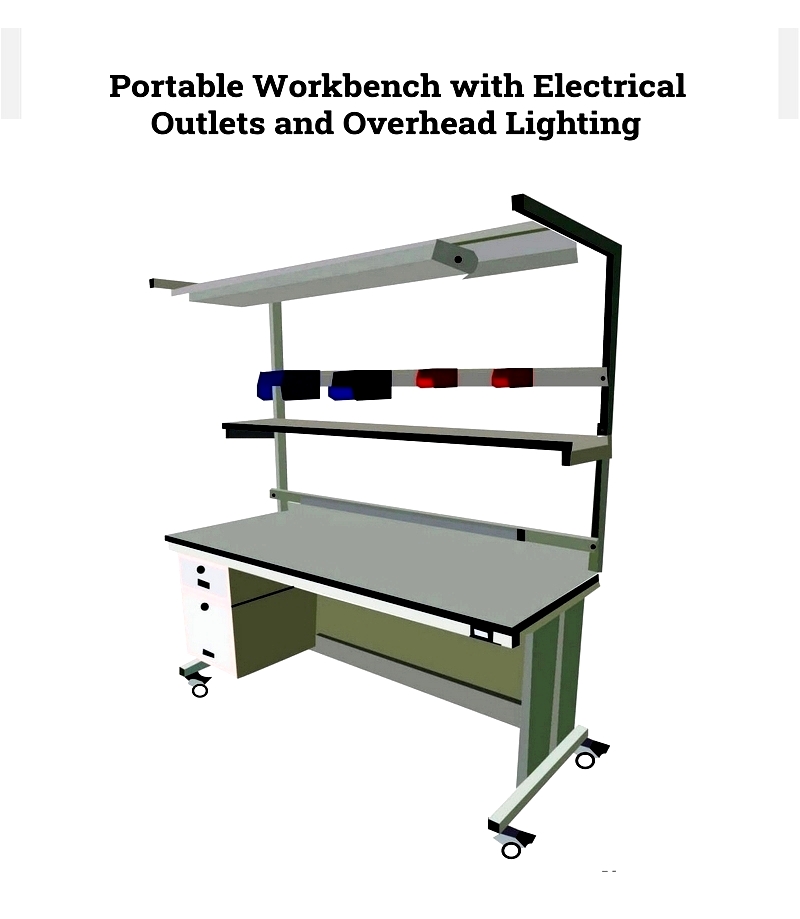

Portable Workbench with Electricity

Designed for powering multiple devices, these workbenches include outlets, USB ports, and cable management. Some feature overhead lighting and grounding systems, making them suitable for labs and high-tech assembly lines.

Static Control

Essential for electronics work, these workbenches prevent electrostatic discharge with anti-static surfaces and grounding points. They're crucial for PCB repair and static-sensitive environments.

Choosing the Right Portable Workbench

Consider your primary application, required features, and work environment when selecting a workbench. evaluate needs for weight capacity, storage, adjustability, and power supply. For job site mobility, prioritize lightweight folding models, while industrial settings may require heavy-duty workstations. Many manufacturers offer customizable options with modular accessories to suit specific workflows.