Introduction

This article provides an in-depth exploration of 3-Way solenoid valves.

Through this article, you'll gain understanding on various aspects including:

- What 3-Way Solenoid Valves are

- How 3-Way Solenoid Valves operate

- Key considerations when selecting 3-Way Solenoid Valves

- Components of a 3-Way Valve

- Manufacturing processes for 3-Way Solenoid Valves

- Different types of 3-Way Solenoid Valves

- Applications of 3-Way Solenoid Valves

- Advantages and limitations of 3-Way Solenoid Valves

- And more...

Chapter 1: Introduction to 3-Way Solenoid Valves and Their Operation

Solenoid valves are electromechanical devices designed to regulate liquid or gas flow. The most common types include direct-acting and pilot-driven valves. Pilot-driven valves control the main orifice through pressure differentials, making them popular for many applications. Direct-acting valves, suitable for low flow rates, directly operate the primary orifice. This discussion focuses specifically on 3-way solenoid valves.

Featuring three ports - orifice, cavity, and stop port - 3-way solenoid valves enable directional flow control. Their "3-way" designation reflects their ability to switch flow paths. These valves come in three operational types: normally-closed (NC), normally-open (NO), and universal configurations. NC valves block flow until energized, while NO valves permit flow when de-energized. Universal valves offer flexibility for either configuration.

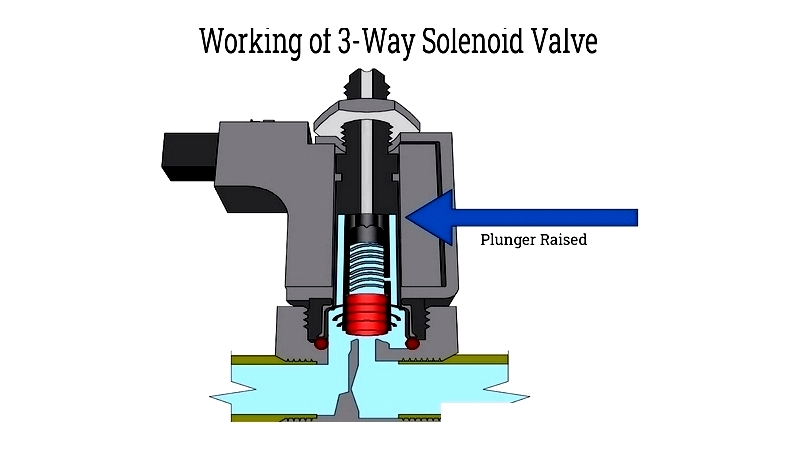

The valve contains two orifices: stop and body. The body orifice remains constantly open, creating two flow paths. When activated, the plunger moves vertically - upward movement seals the stop orifice while opening the body orifice, and downward movement does the opposite.

How 3-Way Solenoid Valves Operate

These valves effectively control fluid flow for opening, closing, dosing, distribution, or mixing operations. While all solenoid valves share basic operational principles, their mechanisms vary by application. Electrically operated valves contain a solenoid coil with a ferromagnetic plunger that moves when energized, opening or closing the orifice.

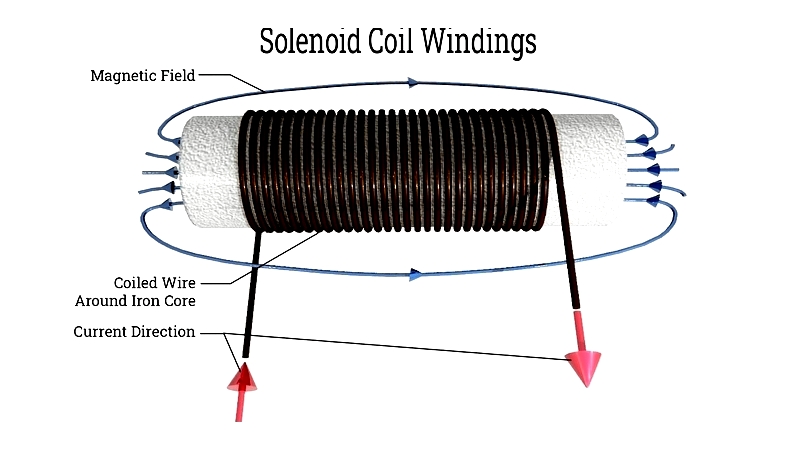

The magnetic field generated by the coil moves the plunger against spring force. The valve body and solenoid form the main components, with the coil assembly often encased in iron or steel for magnetic efficiency. NO and NC configurations determine the default state, with the plunger position controlling flow when de-energized.

Copper wire coils create strong magnetic fields when energized, overcoming spring resistance to move the plunger. This converts electrical energy to mechanical action, opening or closing the valve. Shading rings in AC coils reduce noise and vibration by creating phase-shifted magnetic fields.

Selection Criteria for 3-Way Solenoid Valves

Medium Compatibility

Valve materials (bronze, aluminum, steel, plastic) must resist chemical corrosion from the medium. Plastic suits many applications but may fail at high temperatures, where metal valves perform better. Stainless steel is preferred for food-grade applications.

Operation Principle

Choose between direct, semi-direct, or pilot-operated valves based on application needs. Direct valves work for simple on/off functions, while pilot-operated valves handle higher flows requiring greater closure forces.

Electrical Requirements

Select appropriate voltage (DC or AC) based on safety and power needs. DC valves offer greater safety for low-voltage applications, while AC provides more power when needed.

Environmental Factors

Consider operating conditions - agricultural valves need weather resistance, while explosive environments require explosion-proof designs. Dusty conditions demand dust-proof valves.

Response Characteristics

Response time varies by design, coil type, pressure, and medium viscosity. DC valves respond slower than AC. Fast-acting valves may cause water hammer in some systems.

Pressure Specifications

Ensure the valve can handle maximum system pressure to prevent damage. Different fluids have specific pressure requirements.

Temperature Range

Valve materials must withstand operating temperatures. Excessive heat can damage coils and components.

Protection Rating

IP ratings indicate protection against solids and liquids. Higher numbers mean better protection.

Size and Connection

Proper sizing ensures system compatibility. Oversized valves waste capacity while undersized valves restrict flow.

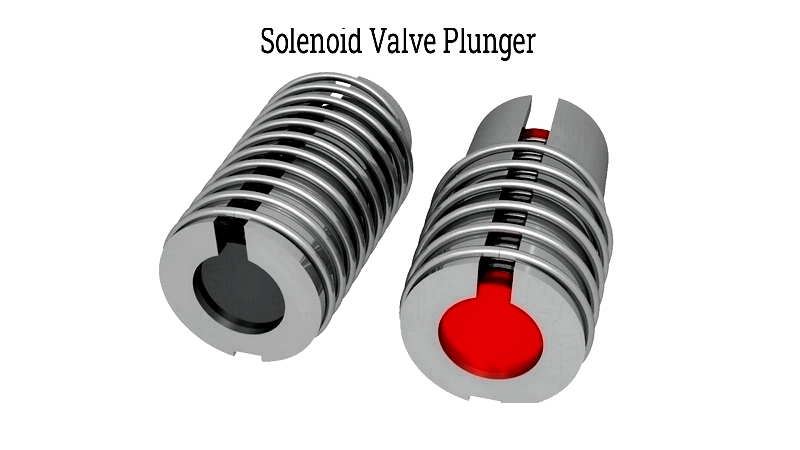

Plunger Stroke

Longer strokes reduce initial solenoid force. Consider stroke-force relationship for optimal performance.

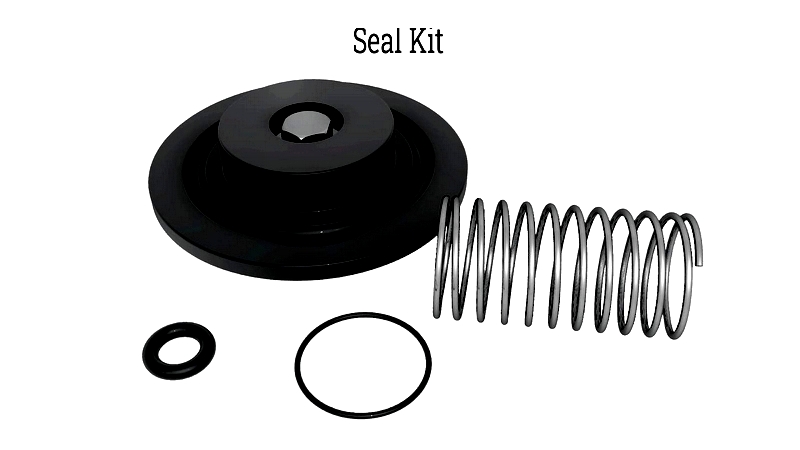

Seal Materials

Choose seals (EPDM, NBR, fluoroelastomer) based on chemical compatibility and temperature requirements.

Duty Cycle

Select NO or NC configuration based on operational needs - NC for quick opening, NO for rapid closing.

Chapter 2: Components and Manufacturing of 3-Way Solenoid Valves

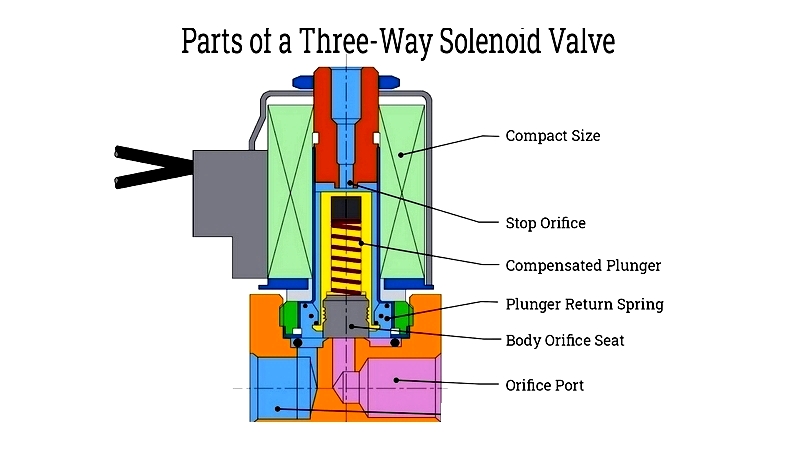

Key Components

Valve Body

The main housing connects to the solenoid assembly and features three ports for flow control. Durable materials like stainless steel or brass ensure resistance to corrosion, pressure, and temperature extremes.

Coil Assembly

Precision-wound conductive wire creates electromagnetic fields for actuation. Coil design affects response speed, strength, and energy efficiency.

Plunger Mechanism

This ferromagnetic component moves to open/close flow paths when energized. Seal materials (rubber, PTFE, metal) ensure leak-proof operation.

Flow Ports

Inlet, outlet, and stop ports enable three-way flow control. Precise port sizing minimizes pressure drop and turbulence.

Electrical Components

The solenoid coil acts as a magnetic switch, while lead wires connect to power sources. Quality insulation ensures safe operation.

Sealing System

Gaskets and diaphragms (EPDM, FKM, PTFE) prevent leaks and withstand chemical exposure.

Manufacturing Process

High-quality valves undergo strict production standards using compatible materials for body and seals. The process combines precision engineering with advanced assembly techniques.

Forging Process

Components are shaped under high pressure after heating for ductility. Secondary processes like sandblasting achieve required finishes.

Precision Assembly

Technicians assemble cleaned components in controlled environments, following strict torque specifications.

Quality Testing

Pressure and leak tests verify integrity at operating conditions. Valves undergo dimensional checks and functionality tests before approval.