Introduction

This article provides an in-depth examination of rotary vane vacuum pumps.

Key topics covered include:

- Operating Principles of Rotary Vane Vacuum Pumps

- Varieties of Rotary Vane Vacuum Pumps

- Applications and Advantages of Rotary Vane Vacuum Pumps

- Additional Relevant Information

Chapter 1: Understanding Rotary Vane Vacuum Pumps

This chapter explores the fundamental aspects of rotary vane vacuum pumps, including their structural design and operational principles.

Definition of Rotary Vane Vacuum Pump

Rotary vane vacuum pumps create low-pressure areas by rotating internal components against their housing. The rotor and casing feature minimal clearances and often incorporate low-friction or self-lubricating materials like graphite, PEEK, or PTFE.

The precise gap between rotor and housing minimizes fluid leakage into the low-pressure zone. These pumps deliver steadier flow with less pulsation than reciprocating models. However, abrasive particles in fluids can damage the clearances. Pump classification depends on rotor design.

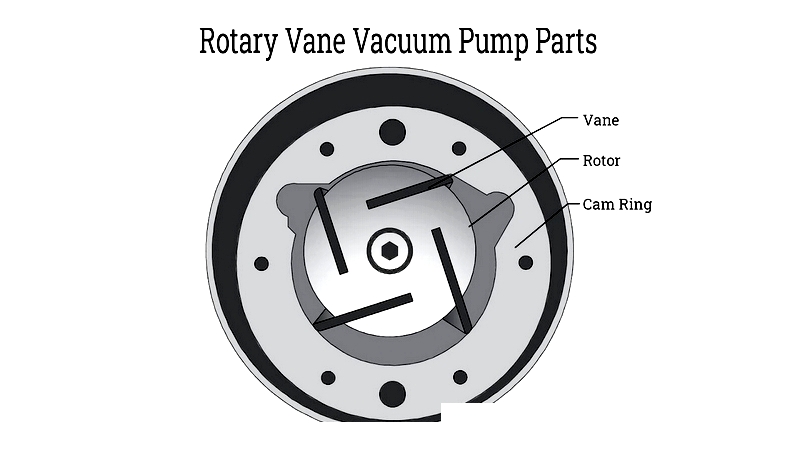

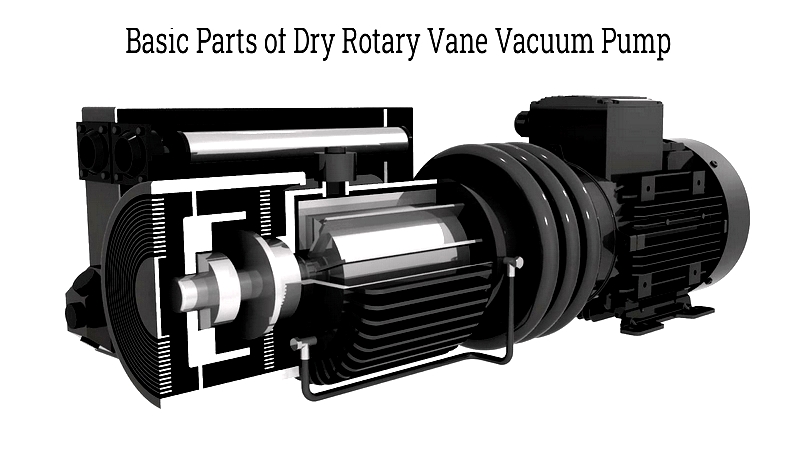

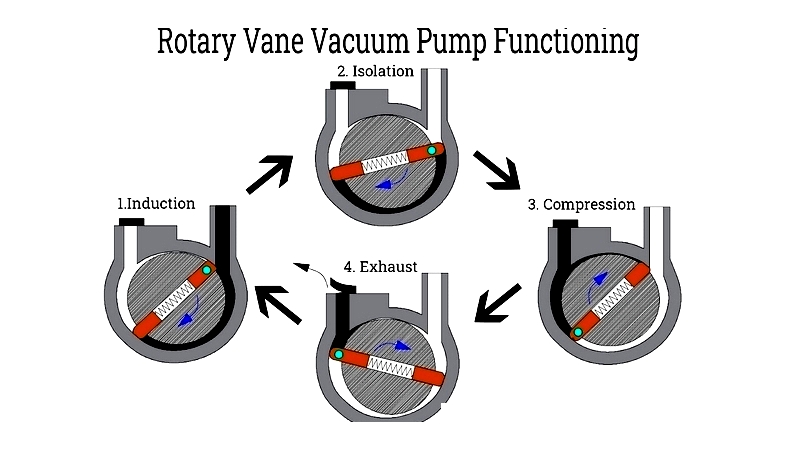

Rotary vane vacuum pumps are among the most common positive displacement vacuum pumps. Their design features radially mounted vanes in an eccentrically positioned rotor within a stator housing. As the rotor turns, vane-separated chambers decrease in size toward the discharge end. Centrifugal force maintains vane contact with the housing, with springs positioning them when stationary.

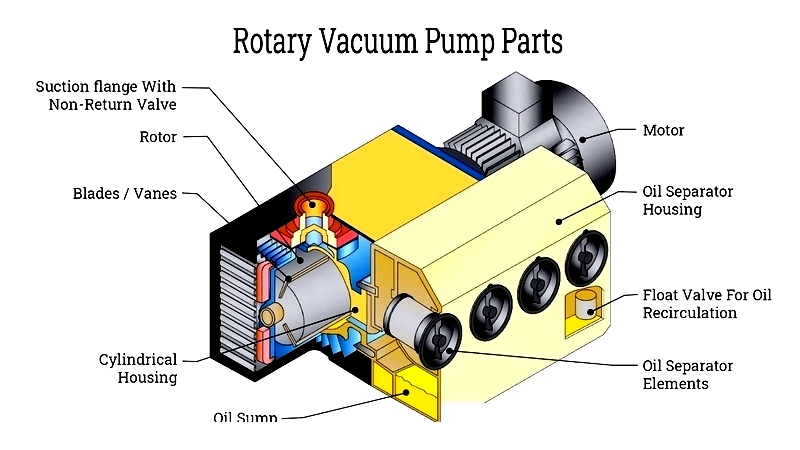

Structural Design Features

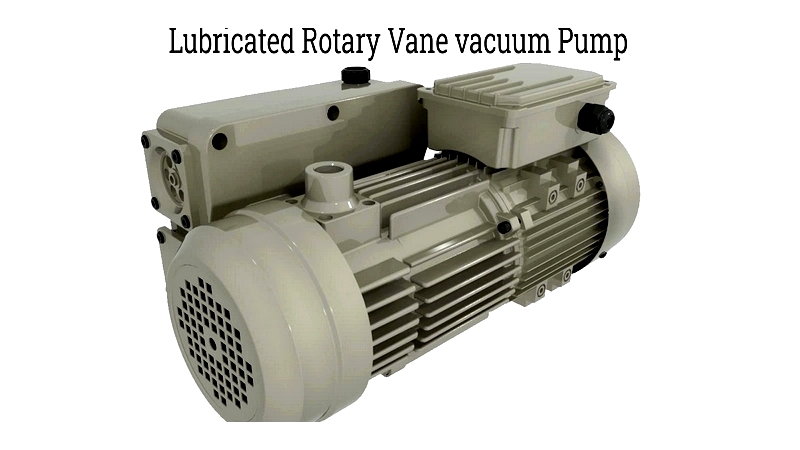

As positive displacement pumps, rotary vane models continuously purge chambers without infinite expansion. This process involves isolating, expelling, and re-expanding pump sections. Available in dry or oil-sealed versions, both ensure effective operation. Dry models rely solely on tight tolerances for vacuum generation.

Wet versions use fluid for lubrication and sealing, while oil-sealed pumps specifically employ oil. Most utilize direct drive mechanisms. While size and configuration vary, core components remain consistent across models.

Lubricated Vane Pump Characteristics

Rotor – Typically copper-wrapped, these rotating components require energy to operate while stators remain fixed to manage electrical currents. Though seemingly simple, their technical aspects can be complex.

Blades and Vanes – Mounted on rotating shafts, these create effective seals against chamber walls, preventing fluid backflow.

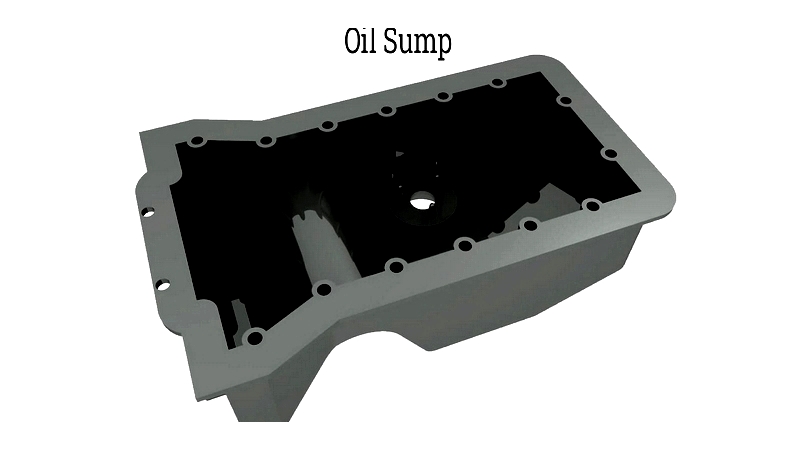

Oil Sump – Stores engine oil crucial for sealing, with pumps circulating filtered oil through the system.

Cylindrical Housing – Typically die-cast aluminum, this enclosure protects internal components.

Suction Flange – Connects suction tubes to hydraulic tanks while preventing leaks and contamination.

Motor – Converts electrical energy to mechanical power through magnetic field interactions.

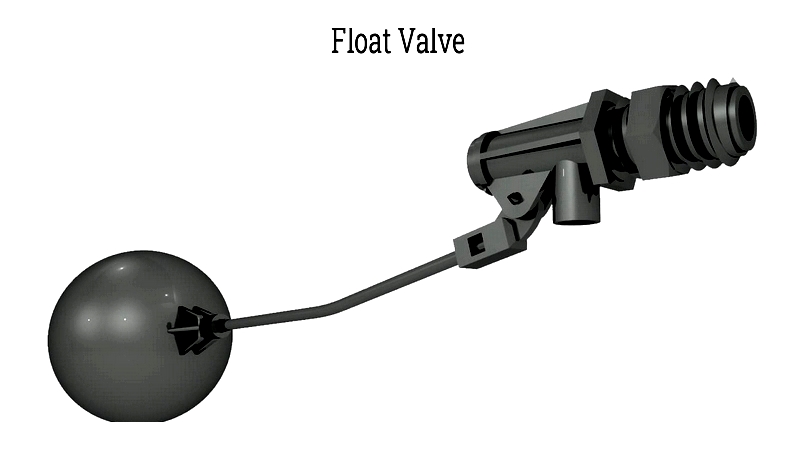

Float Valve – Automatically regulates fluid levels based on oil level changes.

Oil Separation Components – Located in the exhaust area, these capture and separate oil mist from expelled gases.

Oil Separator Housing – Contains separation elements and oil sump.

Oil – Essential for both lubrication and sealing during operation.

Dry-Running Pump Structure

Pressure Regulating Valve – Maintains predetermined output pressure levels for sensitive equipment.

Motor Fan – Blade-equipped disk creating suction through rapid rotation.

Exhaust Silencer – Heat-resistant component reducing operational noise.

Vacuum Pump Fundamentals

These pumps create partial vacuums by removing gas molecules from sealed chambers. Vacuum levels range from low (1-0.03 bar) to extremely high (down to 10^-12 bar), with applications spanning industrial processes to scientific research.

Two main categories exist: gas transfer pumps (mechanical expulsion) and entrapment pumps (molecular capture). Positive displacement models expand/contract chambers using check valves, while momentum transfer pumps accelerate gases to create low-pressure zones.

Material Composition

Standard materials include:

- Exterior Components – Typically cast iron, stainless steel, or ductile iron

- Cast Iron – Economical with excellent machinability and wear resistance

- Ductile Iron – Superior impact resistance compared to standard cast iron

- Steel – Durable, corrosion-resistant, and flexible for various designs

- Vaned Pushrods – Usually carbon graphite or PEEK for self-lubrication

- Carbon Graphite – Withstands high temperatures and corrosive environments

- PEEK – High-performance thermoplastic with exceptional mechanical properties

Operational Principles

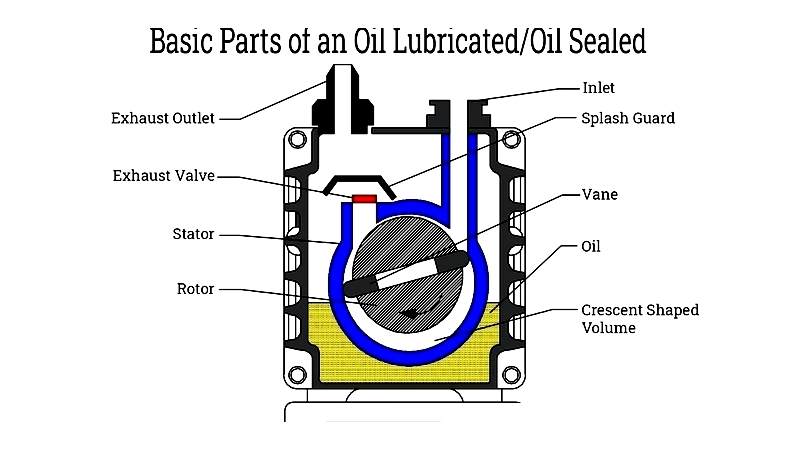

Lubricated Pump Operation

Pressure increases through volume reduction, with oil layers reducing wear. Eccentric rotor positioning creates three chambers that draw in, compress, and expel air through the separation system.

Dry Pump Operation

Functions similarly without lubrication