Introduction

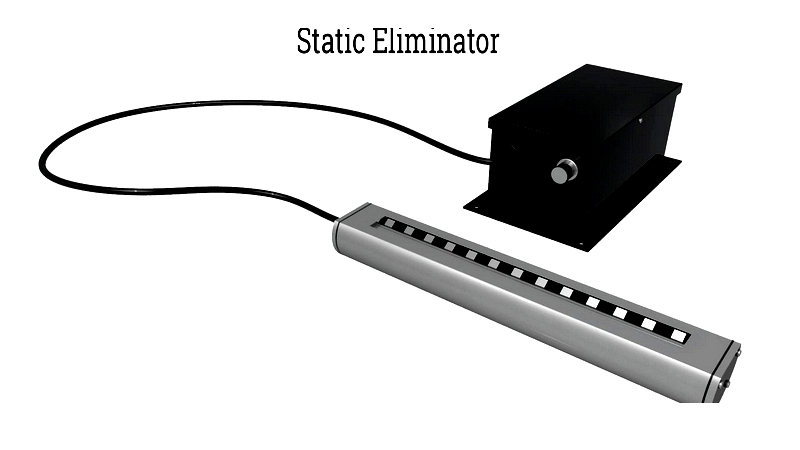

This section covers static eliminators, including their applications, manufacturers, and different types available.

You will learn about:

- The fundamentals of Static Eliminators

- Various Static Eliminator types

- Practical applications of Static Eliminators

- Manufacturing processes of Static Eliminators

- Additional relevant information

Chapter 1: Understanding Static Eliminators

Static eliminators are specialized devices that emit positive or negative ions to neutralize static electricity in equipment and products, preventing operational issues during manufacturing. These devices work by attracting opposite charges to balance electrostatic forces. In industrial environments, charged surfaces often attract dust and contaminants, which can compromise product quality and machinery performance.

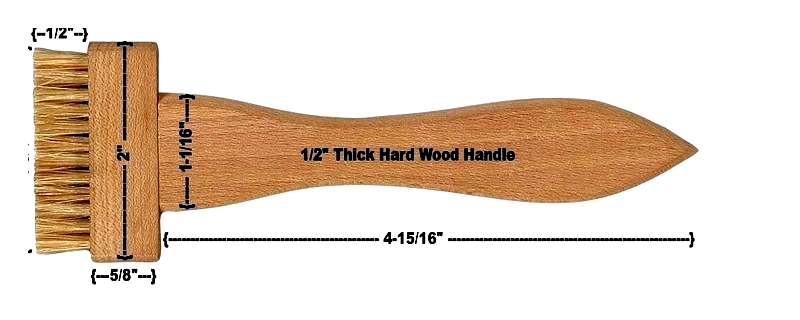

WA24HH ESD Brush By Gordon Brush Mfg. Co., Inc.

WA24HH ESD Brush By Gordon Brush Mfg. Co., Inc.Static electricity typically results from friction, pressure, or material separation, especially with non-conductive materials - a phenomenon known as the triboelectric effect. The intensity of static charge is measured in coulombs, representing the quantity of electric charge transferred by one ampere in one second.

Materials for static control fall into three categories: conductive, dissipative, and insulative. Conductive materials allow free charge movement, dissipative materials slow charge transfer, while insulative materials prevent charge movement. Dissipative materials offer optimal resistance for industrial static management.

The EOS/ESD Association, an ANSI-accredited organization, defines antistatic materials as those that minimize static generation through triboelectric activity. Static issues stem from electrostatic overstress (EOS) and electrostatic discharge (ESD), which can damage electronic components when charges exceed design limits or transfer between objects.

499SDX ESD Brush By Gordon Brush Mfg. Co., Inc.

499SDX ESD Brush By Gordon Brush Mfg. Co., Inc.Static electricity causes multiple problems including material adhesion, sheet repulsion, and reduced production efficiency. These issues degrade product quality and disrupt operations.

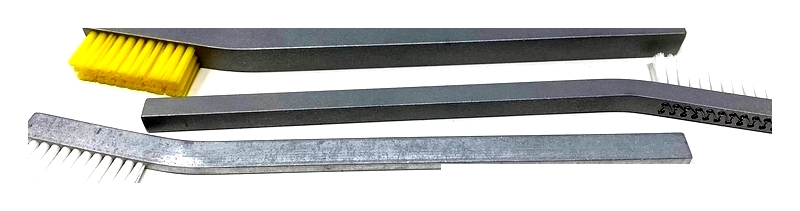

900437T Static Eliminator Brush By Gordon Brush Mfg. Co., Inc.

900437T Static Eliminator Brush By Gordon Brush Mfg. Co., Inc.Static eliminators provide the solution, available as either active (powered) or passive (non-powered) devices. Active models use electrical current to generate neutralizing ions, with various sizes and configurations for different applications.

11S9A, 22S9A & 33SDA Antistatic Brushes By Gordon Brush Mfg. Co., Inc.

11S9A, 22S9A & 33SDA Antistatic Brushes By Gordon Brush Mfg. Co., Inc.Passive devices operate without external power, activated by existing static fields. Cost-effective and easy to install, they effectively reduce static up to 2000 V, with common types including brushes, tinsel, and cords.

Chapter 2: Active Static Eliminator Solutions

Static electricity presents significant challenges in manufacturing, particularly in dry conditions. It can disrupt operations, affect product quality, and create safety hazards. Industries like printing, electronics, and plastics require precise static control to prevent defects and equipment damage.

1HH ESD Brush By Gordon Brush Mfg. Co., Inc.

1HH ESD Brush By Gordon Brush Mfg. Co., Inc.Active static eliminators use high-voltage ionization to produce balanced ion streams that neutralize surface charges. While passive solutions like brushes were historically common, modern active systems offer superior performance and adaptability.

Ionizing Bars

These devices create electrical fields that ionize air molecules, neutralizing static on passing materials. Available in various lengths, they're ideal for production lines and can be enhanced with compressed air for larger coverage areas.

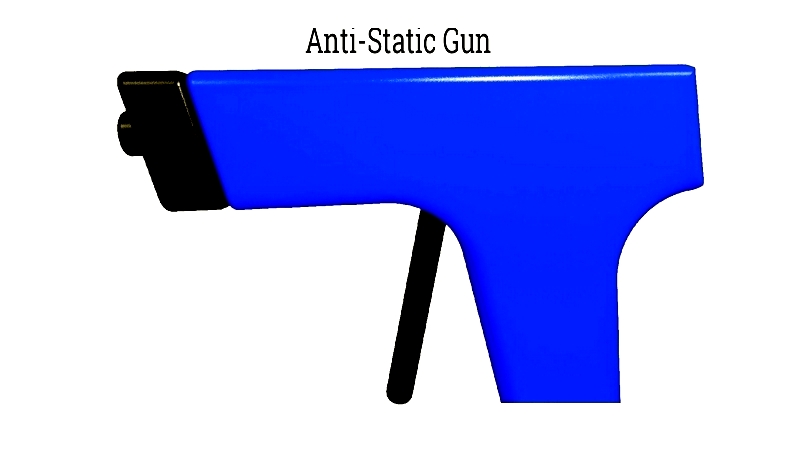

Ionizing Guns

Handheld devices that deliver targeted ion bursts for precise static removal on sensitive components, featuring ergonomic designs for operator comfort.

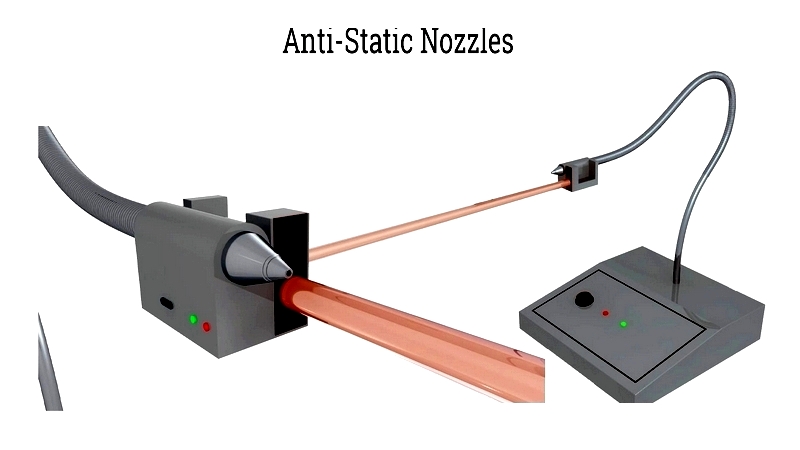

Ionizing Nozzles

Compact devices for hard-to-reach areas, using compressed air to deliver ionized streams that clean and neutralize surfaces.

Ionizing Blowers

Designed for large-area static control, these units produce high volumes of ionized air for workstation protection.

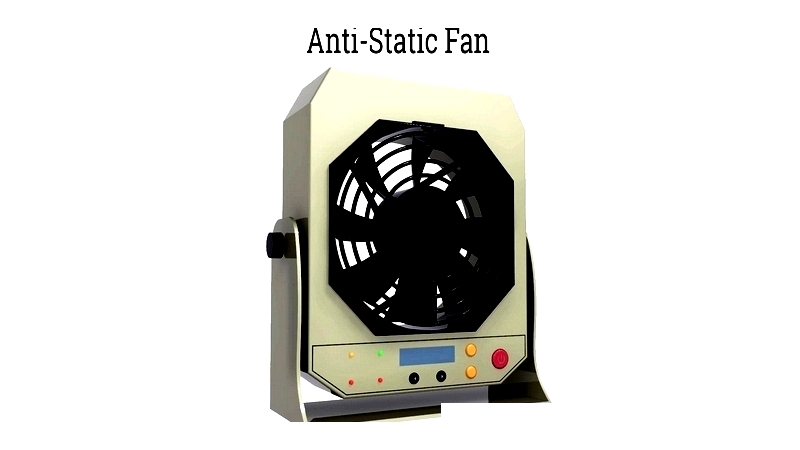

Ionizing Fans

Portable solutions for targeted static control, ideal for electronics workstations and testing facilities.

Air Knife Systems

Combine ionizing bars with high-velocity air streams for effective static and contaminant removal in processing applications.

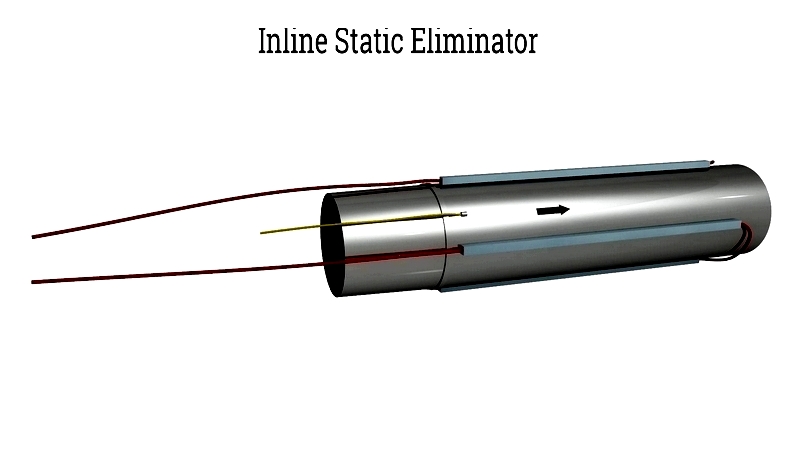

Inline Eliminators

Specialized units for pneumatic systems that prevent static-induced material blockages in conveying pipelines.

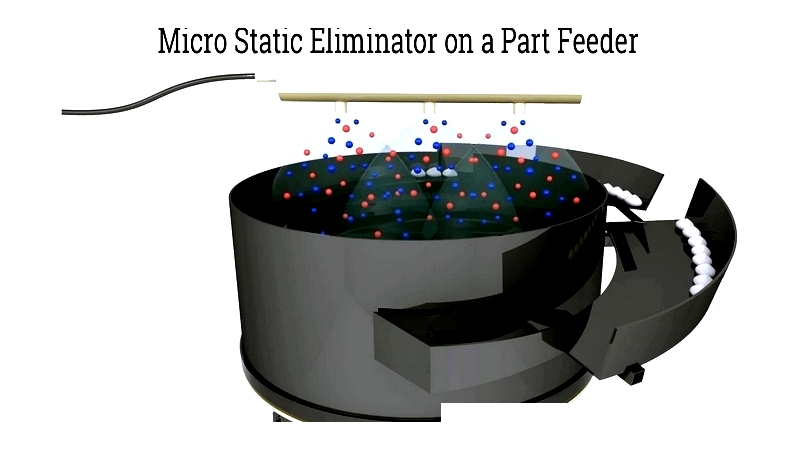

Micro Eliminators

Compact devices for integration into small spaces, featuring monitoring capabilities for precision applications.

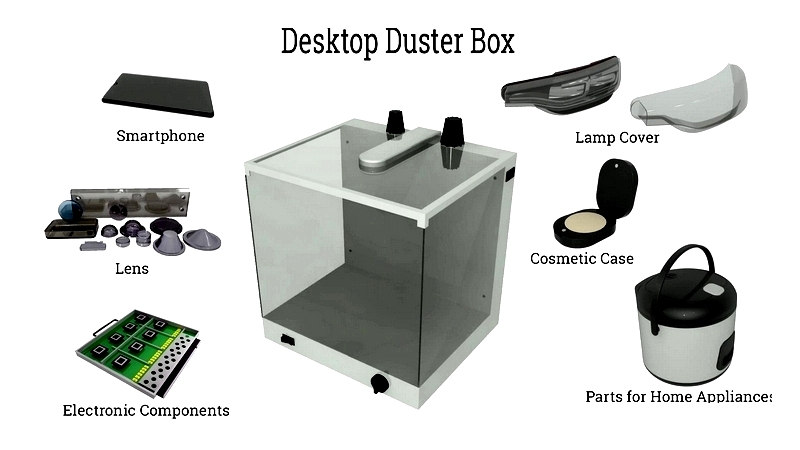

Desktop Cleaning Systems

Enclosed units for automated static removal and cleaning of sensitive components in controlled environments.

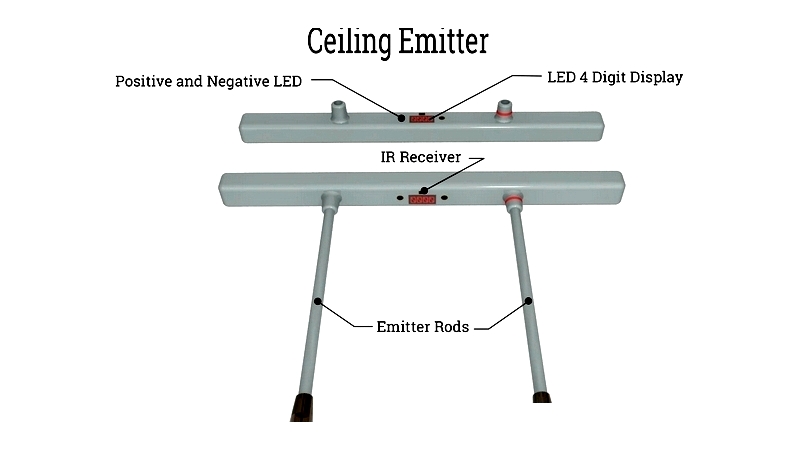

Ceiling-mounted Systems

Large-scale ionization solutions for cleanrooms, providing uniform static control without disrupting airflow.

AC vs DC Technology

AC systems suit close-range applications, while DC models offer greater range and control for