Introduction

This article provides an in-depth exploration of stainless steel tubing.

It covers detailed information on various topics including:

- Principles of Stainless Steel Tubing

- Types of Stainless Steel Tubing

- Applications and Benefits of Stainless Steel Tubing

- And More...

Chapter 1: Understanding the Guiding Principles of Stainless Steel Tubing

This section examines the characteristics of stainless steel tubing, including its manufacturing process and functional applications.

Defining Stainless Steel Tubing

Stainless steel tubing is a durable material known for its corrosion resistance and low maintenance requirements. The sizing and types of stainless steel tubes are designed to meet specific application needs.

Many people confuse piping with tubing due to their similar round cross-sections. However, unlike pipes, which are typically circular, tubes can also be square or rectangular.

The primary difference between pipes and tubes lies in their applications. Pipes are mainly used for transporting gases and liquids and are measured by their internal diameter (ID), while tubes are generally structural components, measured by their external diameter and wall thickness.

Due to its strength, corrosion resistance, and minimal maintenance, stainless steel is a preferred material for architects and manufacturers. For structural purposes, stainless steel tubing must be accurately sized according to its outer diameter and wall thickness. The type of tubing selected depends on specific applications, which may include fractional, hypodermic, square, or metric tubing.

Production of Stainless Steel Tubing

Various methods are used in the manufacturing of stainless steel tubing, including:

Tube Mill Process

This method involves the following steps:

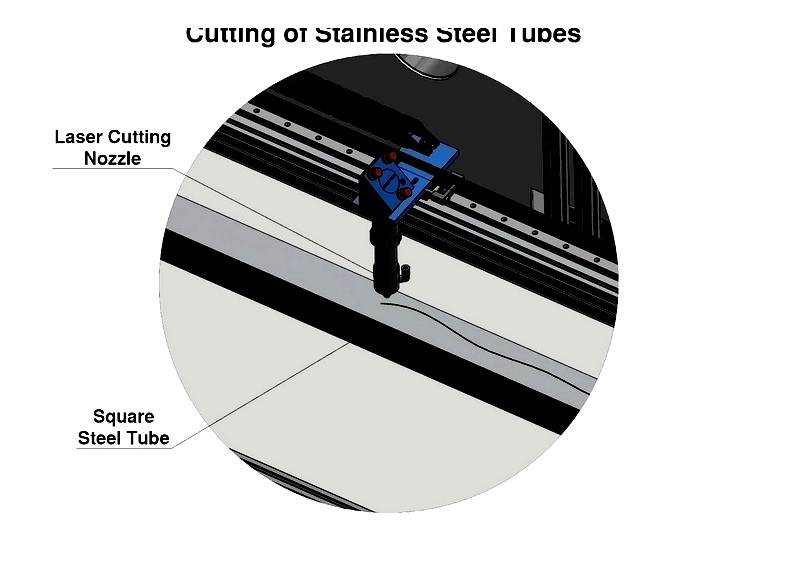

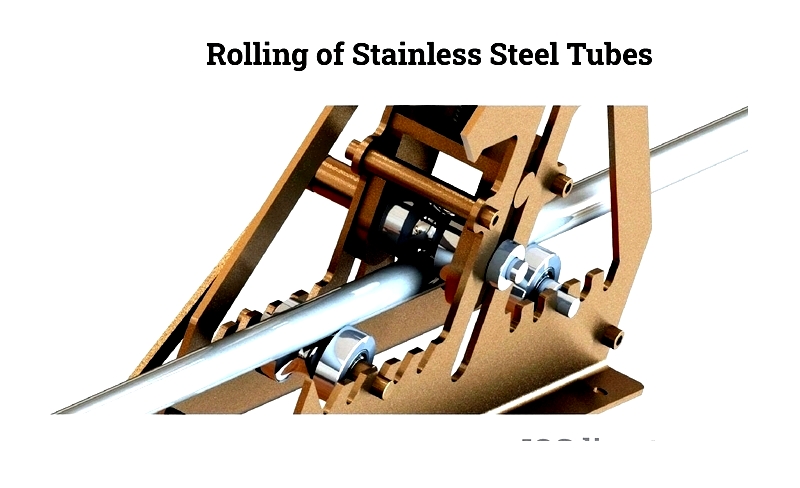

Rolling and Welding

In the rolling and welding process, stainless steel coils are continuously deformed into tubes on a tube mill. Techniques such as TIG, high-frequency, and laser welding are used to join the strip edges. Edge preparation may be necessary to ensure a high-quality weld. The weld bead on both the inner and outer diameters is then removed through scarfing, sanding, or bead rolling, depending on the final application and specifications.

Cleaning and Heating

The newly formed stainless steel tubes are cut to industry-specific lengths and cleaned to remove impurities. They are then heat-treated to relieve stresses caused during welding and forming. This process occurs in a continuously rolling hearth furnace with precise temperature controls. After heat treatment, the tubes are straightened and pickled to remove surface scales.

Cold Drawing

When desired sizes are not achievable from the mill, a cold drawing process may be used. During cold drawing, the tubes or pipes are coated with a lubricant solution to reduce friction and drawn over a bench using die plugs.

Finishing Process

The extended tube or stainless steel pipe undergoes cleaning, heat treatment, pickling, and straightening. Final products are marked with computerized inkjet technology and labeled with material grade, heat number, size, and third-party inspection stamps. Rigorous testing and quality control are conducted before packaging and shipping.

Seamless Extrusion

Extrusion, gun drilling, and piercing are common methods for creating seamless stainless steel tubing. Extrusion offers the most consistent exterior diameters, resulting in concentric internal diameters. It is particularly effective for producing long-length seamless steel coil tubing. The process begins with a hot-extruded seamless pipe, which undergoes cold processing.

During cold pilgering, the raw material is shaped into a long, straight form using tube reducers or pilger mills. This method reduces both wall thickness and diameter in one step, maintaining consistent dimensions. It can achieve cross-section reductions of over 90% in a single cycle for certain materials.

Lubricants are applied to the tube's external and internal diameters during reduction and later degreased before annealing. This process typically produces stainless steel tubes ranging from 40 to 160 feet in length.

Coiling Tube

Specialized machinery cold-draws a straight tube into a coiled form, reducing its outside diameter, inside diameter, and wall thickness while elongating the tube.

Main Drawing

Floating plug drawing involves pulling tubing through a conical die with a floating plug inside. The final dimensions are determined by the die and plug sizes, resulting in a smooth finish ideal for light-wall items.

Sink drawing pulls tubing through a conical die to set the inside diameter and wall thickness, suitable for high-pressure applications requiring greater wall thickness.

Lubricants are applied to both the outer and inner diameters of the tubes and later degreased, typically in a solvent tank.

Vacuum Annealing

After cold reduction, stainless steel tubing and coils undergo annealing to reduce internal stresses and restore the crystalline structure. Rapid cooling transforms the material from a hardened state to a softer, more pliable form.

This annealing process is repeated until the tube meets specified dimensions.

Hydrotest Tubing

This type of tubing must meet strict ASTM standards and undergo detailed inspections before reaching customers. Hydrostatic testing validates structural integrity and provides data on mechanical properties, material defects, and potential failure points.

Final Touches on Stainless Steel Tubing

Stainless steel coil tubing can be rolled onto spools for shipment or straightened and cut to customer-specified lengths. Products may be polished and marked for traceability.

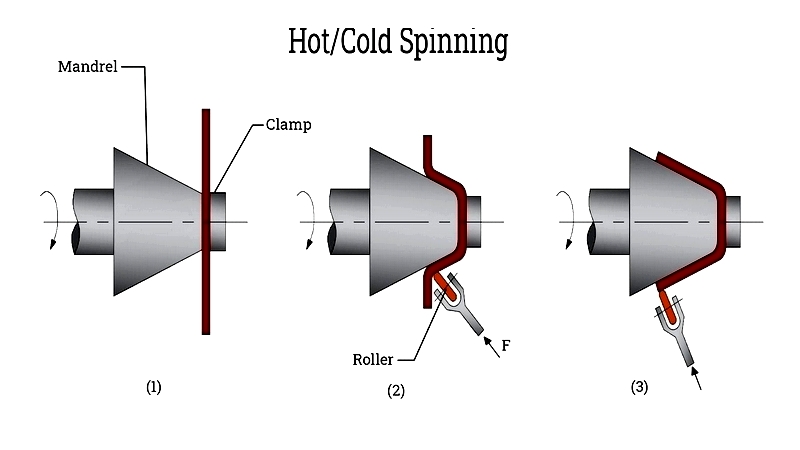

Drawn Over Mandrel (metal Spinning)

A small mandrel is placed inside a tube to maintain its shape during drawing, preventing wrinkling. The tube passes through a die with a smaller opening, contracting to the desired diameter. This method allows for precise tolerances.

DOM Tubing starts with a CREW tube or hollow form. The larger ERW tube is "tipped" to allow the trolley to grip it, pulling the tube through the die. A carbide mandrel is inserted into the raw tube's bore, and the tube is lubricated and drawn through the die.

The die and mandrel determine the final tube dimensions. High-angle dies reduce thick-walled tubes, while low-angle dies are used for thin-walled tubes.

Multiple Passes

The DOM process may require several passes depending on polishing requirements, dimensional needs, and mechanical or metallurgical specifications.

Mandrel and Rod Removal

After drawing, the mandrel is removed by applying pressure to rotate the tube through rollers. Additional drawing may be needed for the desired finish.

Computer Aided Design (CAD)

CAD technology replaces traditional trial-and-error in die design