Introduction

This article provides an in-depth exploration of metal mesh.

It covers detailed information on the following topics:

- Principle of metal Mesh

- Types of metal Mesh

- Materials and Patterns in metal Mesh

- Benefits and Applications of metal Mesh

- And more...

Chapter 1: Understanding the Principle of metal Mesh

This section examines the concept of metal mesh, including its manufacturing process and key design considerations.

Defining metal Mesh

"Wire mesh" typically refers to structures made from interconnected metallic wires using various techniques, forming flat or three-dimensional frameworks. This versatile material finds widespread use in transportation, fencing, displays, and protective barriers, serving important roles in both industrial and everyday applications.

metal mesh sheets are produced from materials like stainless steel, galvanized steel, carbon steel, aluminum, copper, bronze, and brass. These materials are processed into wires of different gauges, then woven or linked to create uniform parallel rows and intersecting columns.

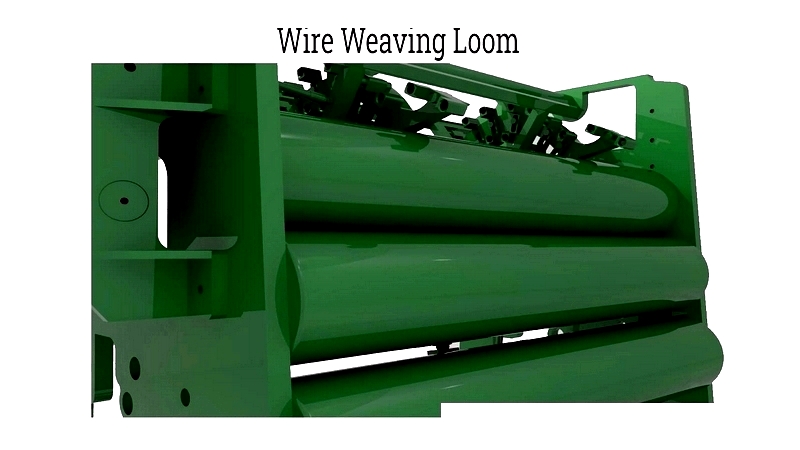

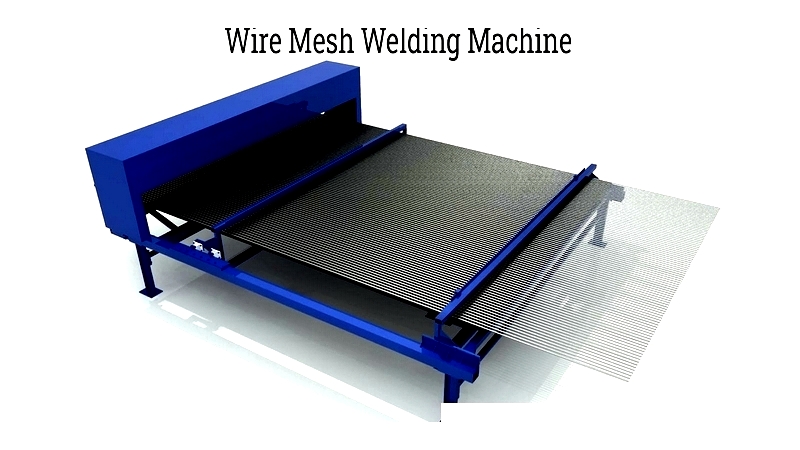

Also called wire fabric or hardware mesh, wire mesh is manufactured using industrial looms that weave wires into square or rectangular patterns. For welded wire mesh, intersecting wires are fused together at junctions using electric welders.

Production of metal Mesh

Steel derived from iron possesses unique beneficial properties. Stainless steel is particularly rust-resistant and durable, making it ideal for various industrial applications. Steel wires are especially suitable for wire mesh production due to their ductility, strength, and flexibility.

Wire mesh has a long history in steel production, with uses spanning thousands of years. As economies grow, steel wire mesh finds new applications in fencing, barricades, machine guards, cages, grills, sifters, and shelving.

Iron welded wire mesh is essential for concrete reinforcement. Steel wire manufacturers supply materials to secondary producers who transform them into mesh through weaving or welding.

Design Considerations for metal Mesh

- Key mesh attributes like spacing, aperture size, and mesh count depend on application requirements. These may be defined by mesh size or aperture size.

- Construction method (woven or welded) significantly impacts mesh strength and durability, with welded wire mesh offering superior qualities.

- Weaving patterns affect the strength and durability of woven wire fabrics.

- Environmental conditions (humidity, temperature, marine exposure) guide material selection.

- Material choice also depends on the processed medium (wet slurries, dry powders, corrosive chemicals).

- Wire diameter is crucial and can be flat, round, or ribbon-like. Specifying wire size in inches or microns avoids confusion.

- Mesh count (wires per unit length) measures mesh size. Large-aperture mesh dimensions are often determined by gaps between wires.

Selection Criteria for metal Mesh

Key considerations include:

Temperature

Understanding temperature limits is essential for heat-resistant wire mesh. Materials range from stainless steel grade 304 (1500°F) to tungsten (5000°F).

Corrosion Resistance

While many wire cloth types can corrode, materials like titanium and specialized alloys offer enhanced protection.

Fluid Viscosity

Viscosity is important in filtration applications. Less dense fluids filter more efficiently, while viscous fluids require appropriate mesh selection.

Particle Size

Particle size determines mesh count, aperture size, and wire thickness. Test sieves help achieve precise measurements.

Pressure Drop

Filter media selection affects pressure drop rates during filtration. Proper mesh selection reduces costs and contamination incidents.

Flow Rates

Flow rate requirements should guide mesh selection, considering viscosity and open area percentage.

Pollutant Types

Pollutant characteristics influence material choice, wire diameter, mesh density, and weave style.

Specific Gravity

Mesh settings may need adjustment based on specific gravity testing requirements.

Chapter 2: Types of metal Mesh

Various metal mesh types include:

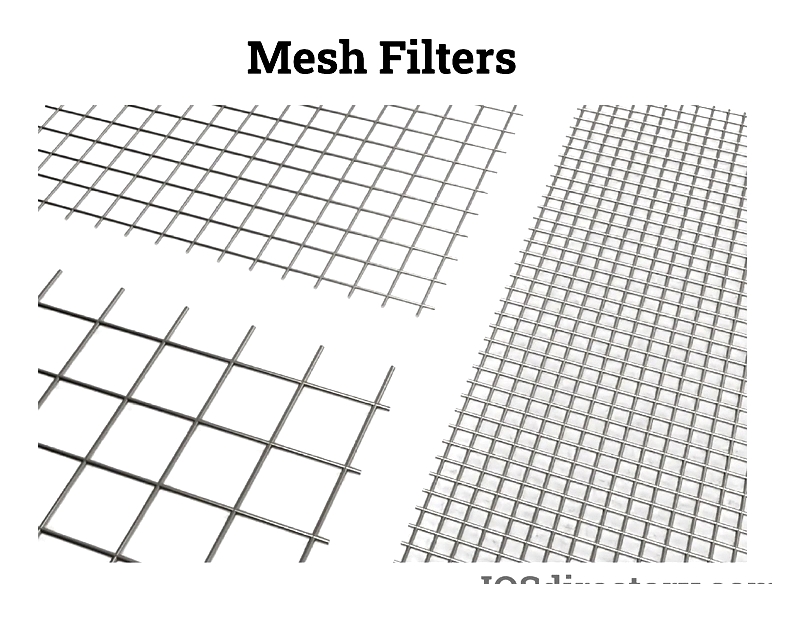

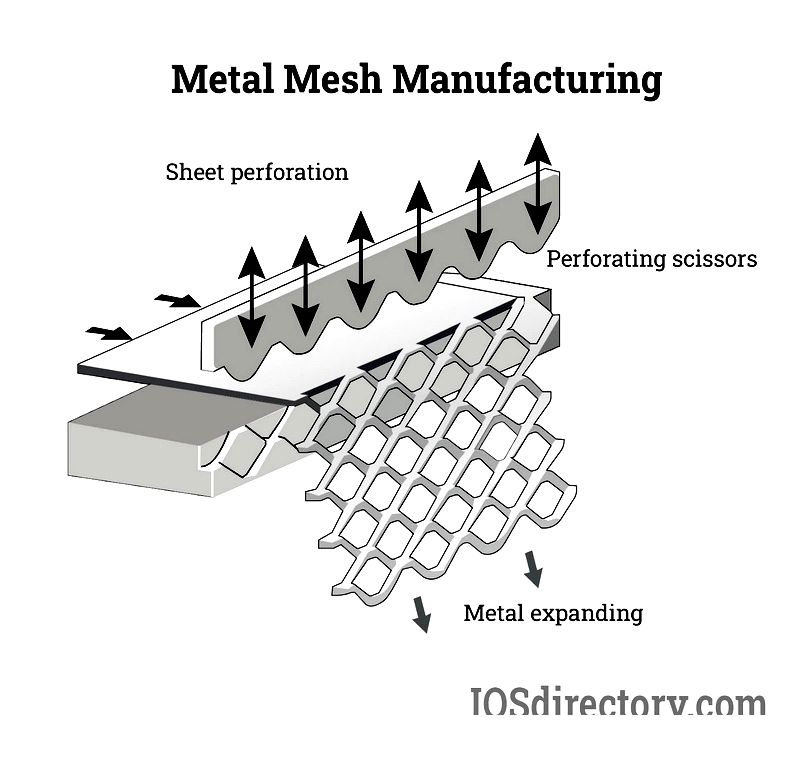

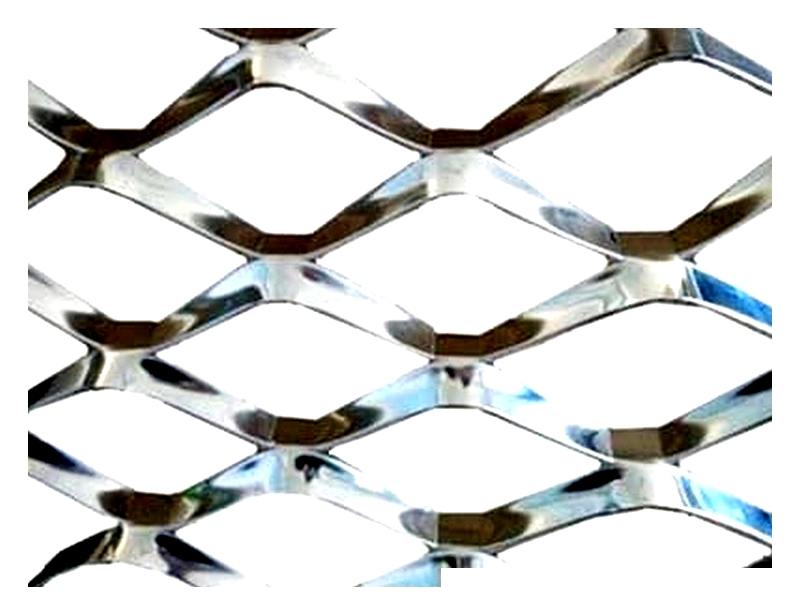

Expanded Wire Mesh

Created by cutting and stretching metal sheets to form patterned mesh with diamond or hexagonal holes. This durable structure is ideal for industrial and architectural uses, offering superior airflow compared to perforated metals.

Woven Wire Mesh

Features intersecting metal wires in precise patterns, typically using Plain Weave or Twill Weave methods. Used widely in filtration, sieving, and screening across various industries.

Welded Wire Mesh

Created by welding steel wires at intersections to form strong grid patterns. Offers greater structural integrity than woven mesh and is used in fencing, concrete reinforcement, and safety guards.

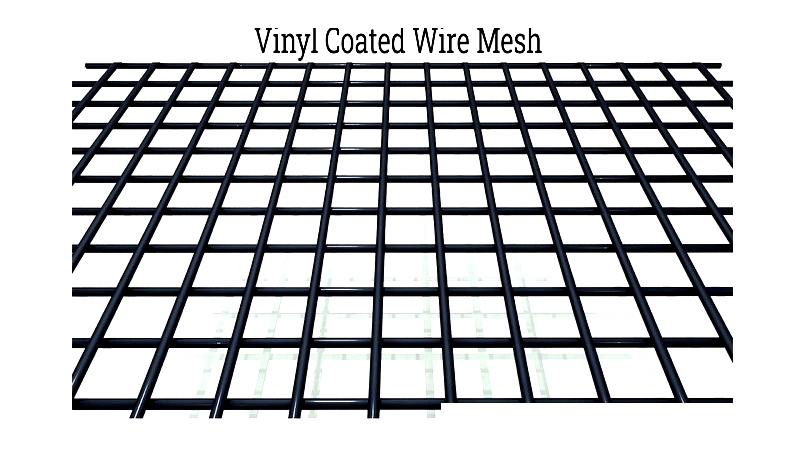

Vinyl Wire Mesh

Features a PVC coating over welded or woven mesh for enhanced durability and weather resistance. Used in fencing, animal enclosures, and outdoor applications.

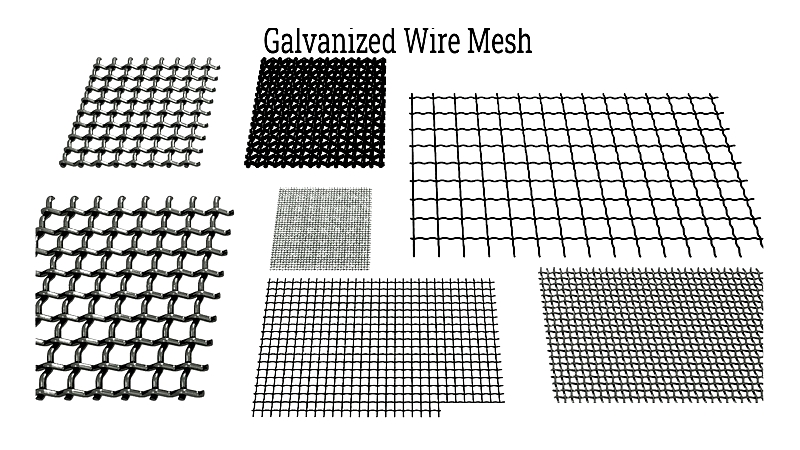

Galvanized Wire Mesh

Zinc-coated for corrosion resistance, suitable for outdoor use in fencing, window guards, and agricultural applications.

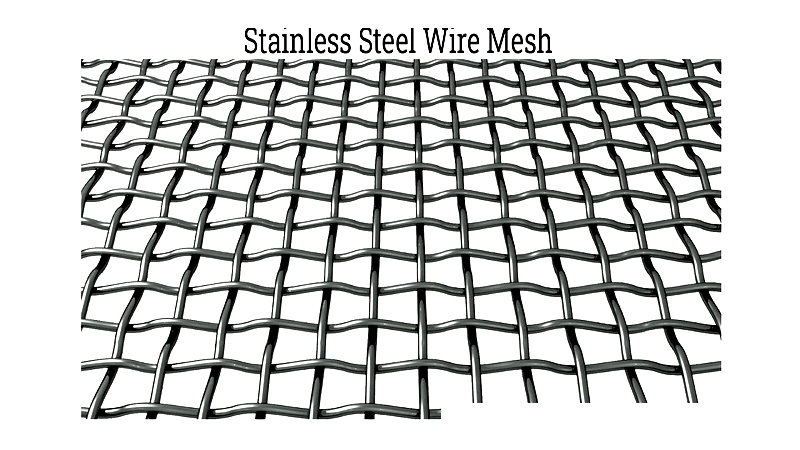

Stainless Steel Wire Mesh

Offers superior corrosion resistance and strength for demanding applications in marine, chemical, and food processing industries.

Wire Netting

Characterized by hexagonal or rectangular woven patterns, used in fencing, agriculture, and erosion control. Provides cost-effective solutions for residential and commercial projects.

Choosing the Right metal Mesh

Selection depends on project requirements, strength needs, environmental exposure, and aesthetic preferences. Consider mesh opening size, wire gauge, coating, and industry standards for optimal performance.