Introduction

This article provides an in-depth examination of torsion springs.

Continue reading to learn about:

- What torsion springs are

- The mechanics behind torsion springs

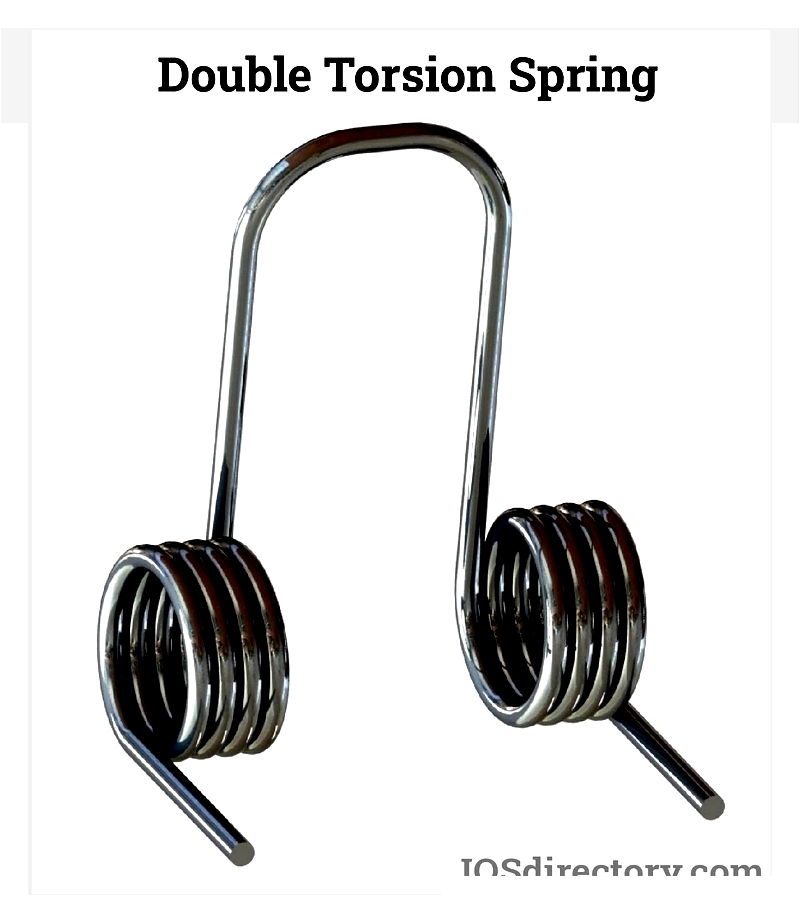

- Different types of torsion springs

- How torsion springs are produced

- Common applications of torsion springs

- And much more...

Chapter 1: What Are Torsion Springs?

Torsion springs are mechanical devices designed to efficiently store and release rotational energy.

These springs connect to mechanical components at both ends. When one end rotates around the spring's axis, the coils tighten, storing potential energy.

During winding, one end moves around the central axis while the other remains fixed. As the coils tighten against increasing rotational force, the spring accumulates more potential energy.

When released, the spring unwinds and rebounds elastically, discharging stored energy. This creates equivalent rotational force on the opposite end, applying torque to the connected part. Torsion springs commonly provide static support for mechanical components.

Their operation relies on resisting rotational forces. The mechanical energy generated from this resistance creates torque proportional to the twist angle. Common types include helical, torsion bar, and spiral wound springs, made from materials like wire, sprung steel, or rubber.

Torsion springs primarily withstand bending stress rather than rotational stress due to their tight winding under torsion. Unlike compression or tension springs that handle linear forces, torsion springs exclusively manage rotational forces.

Their mechanical performance depends on material elasticity, allowing them to return to original shape after twisting. These springs can rotate clockwise or counterclockwise and must twist along their winding direction for maximum force impact.

Widely used across industries, torsion springs come in various configurations to meet diverse requirements.

Chapter 2: Mechanics of Torsion Springs

Torsion springs are helical components that store and release rotational energy or maintain mechanisms in position by twisting along their central axis. Unlike compression or extension springs, they generate torque rather than linear force, making them ideal for applications requiring angular force or controlled rotation. Common uses include hinges, garage doors, clothespins, automotive assemblies, and industrial machinery.

During deflection (twisting), the spring's diameter decreases while its length increases, efficiently storing mechanical energy. This principle is fundamental for both custom and commercial spring designs.

The winding direction must match application requirements. During assembly, the load-bearing leg must be correctly positioned (left or right) for proper alignment. Torsion springs typically mount on mandrels corresponding to the application's hinge line.

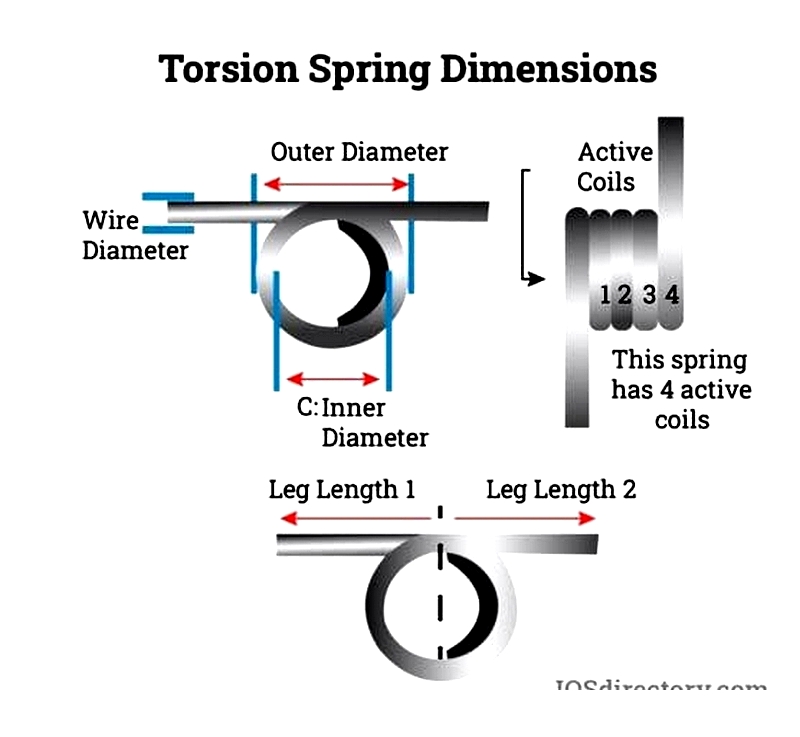

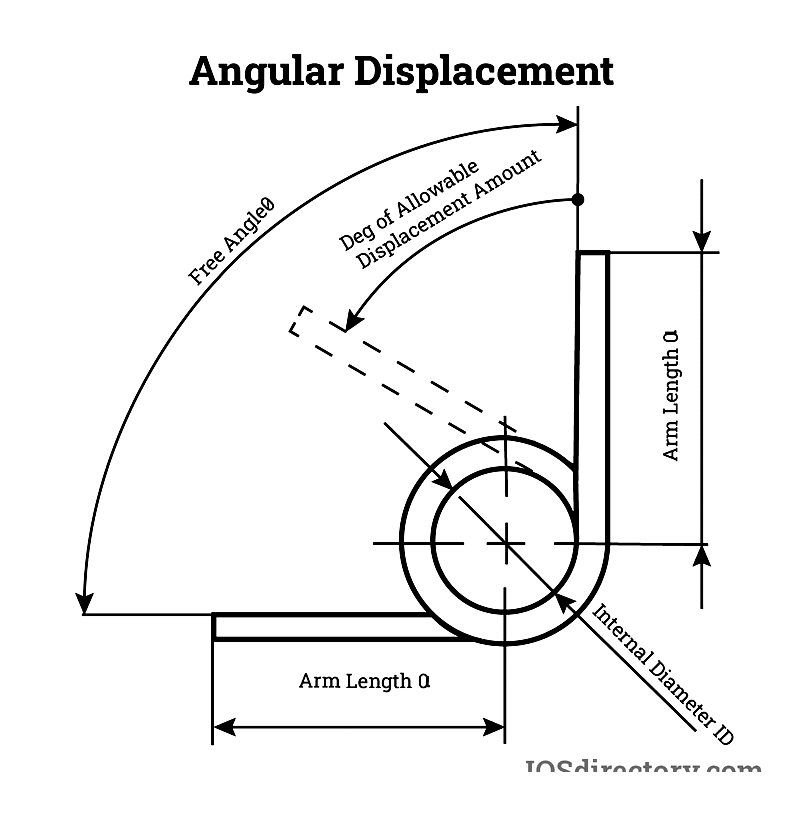

Inner Diameter

The inner diameter measures the width inside the coil's helix, perpendicular to the centerline. This determines the maximum shaft or mandrel size that fits inside. For optimal operation in rotating assemblies, include 10% clearance to prevent binding.

Engineers must consider material expansion in high-torque or high-temperature environments when specifying inner diameter.

Outer Diameter

The outer diameter measures the complete outside width of the coil's helix. This defines the housing diameter needed, accounting for tolerances to ensure free operation without excessive movement.

Wire Diameter

The wire diameter is the thickness of the spring wire, influencing torque output, durability, and stress resistance. Mean diameter (outer diameter minus wire diameter) affects stress distribution and spring rate calculations.

Body Length

The body length measures the spring's unloaded length across the end coils. Under torque, length increases while active coil diameter decreases, affecting available torque.

Leg Length

The leg length measures from the leg end to the coil's centerline. Shorter legs require greater torque to initiate coiling. Different leg lengths allow custom configurations in tight spaces.

Total Coil

The total coil counts all active coils that twist under load. This is slightly less than physical coils due to inactive leg portions. For springs with 0° leg angles, total coil is a whole number.

Pitch

The pitch measures the distance between adjacent active coils. In closely-wound springs, pitch nearly equals wire diameter. Designers typically specify total coil count and body length rather than pitch.

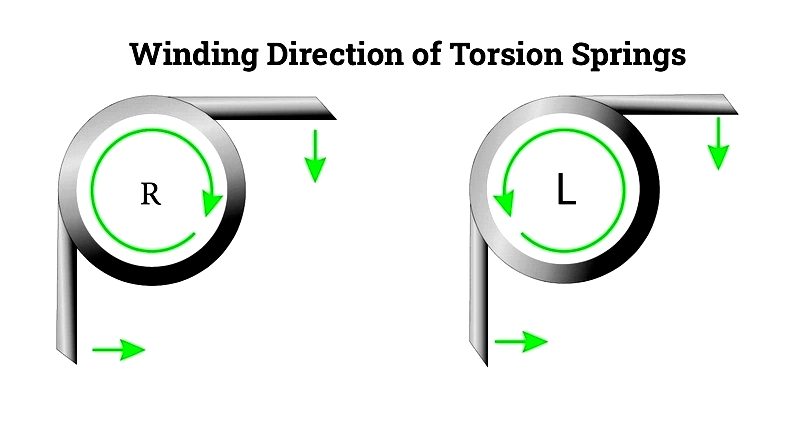

Winding Direction

Torsion springs have specific winding directions (right-hand or left-hand). Right-hand winds clockwise; left-hand winds counterclockwise. The direction must match the application's force direction.

Load and winding direction must align. Opposite directions require reduced load and deflection. Proper winding ensures mechanical function and longevity.

In right-hand springs, the back leg torques clockwise while the front leg torques counterclockwise. Left-hand springs reverse this motion.

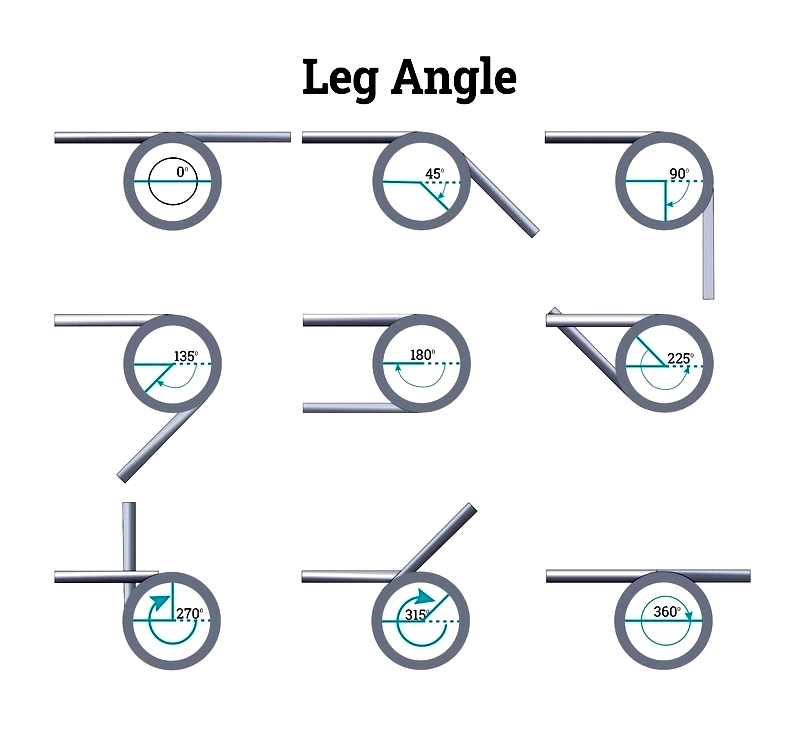

Leg Angle

The leg angle measures between legs when unloaded (0°-360°). Standard angles include 90°, 180°, 270°, and 360°, but custom angles are available.

Leg angle affects total coil count. The relationship is:

Leg Angle at Free Position = Number of Inactive Coils × 360°

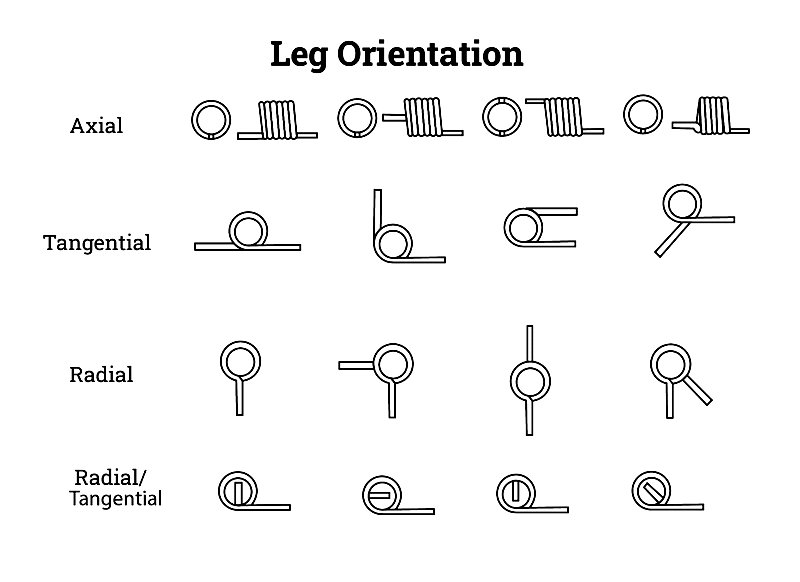

Leg Orientation

Leg orientation describes how legs bend relative to spring diameter and installation axis. Sharp bends increase stress. Common orientations include axial, tangential, radial, and radial-tangential. Tangential configurations typically experience least stress.

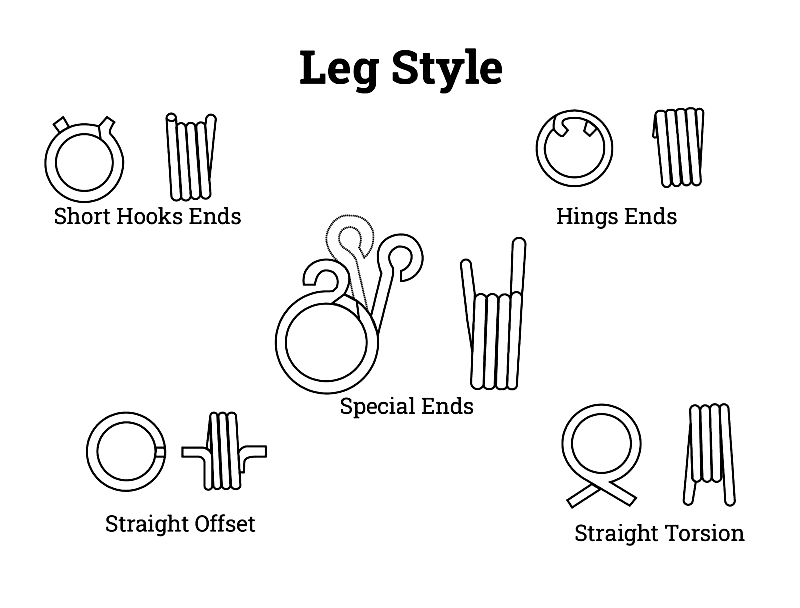

Leg Style

Torsion spring legs come in various styles for installation and force application:

- Straight Legs

- Straight Offset Legs

- Short Hook Ends

- Hinged Ends

- Looped Ends

Spring Index

The spring index (mean diameter ÷ wire diameter) indicates coil tightness and strength. Lower indexes mean stronger springs but higher manufacturing complexity. Ideal indexes range from 6-12.

Angular Deflection

Angular deflection measures how far a spring leg travels from free to loaded position, determining safe rotational range.

Maximum Deflection

The maximum deflection is the greatest safe angle before risking deformation or failure. High-rotation applications use more coils and lower stresses for durability.

Maximum Load

The maximum load is the highest safe torque before yielding or deformation occurs. Applications