Introduction

This article provides an in-depth exploration of wire mesh.

You will learn about various topics including:

- Fundamentals of Wire Mesh

- Materials Used in Wire Mesh Production

- Applications of Wire Mesh

- Advantages of Using Wire Mesh

Understanding Wire Mesh Fundamentals

Wire mesh, also referred to as wire fabric, wire cloth, or hardware mesh, is created by weaving, interlacing, or welding wires of varying thicknesses into uniform rows and intersecting columns. Industrial looms produce square or rectangular openings between wires, while welded wire mesh is formed by electrically fusing intersecting longitudinal wires.

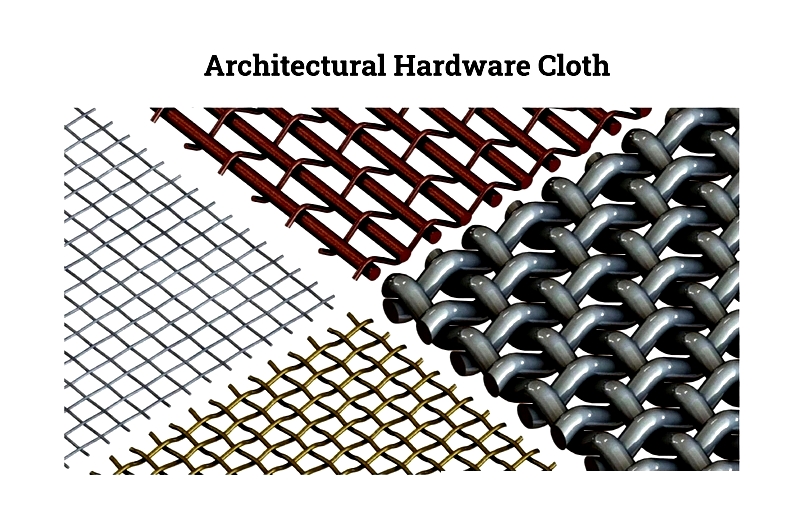

Wire mesh comes in countless shapes, sizes, and configurations, made from various durable materials. These configurations primarily serve to separate, screen, structure, and protect different applications. Common wire materials include galvanized steel, stainless steel, aluminum, steel, and copper alloys. The choice of wire type depends on factors like intended use, required tensile strength, durability, lifespan, and flexibility.

Wire Mesh Manufacturing

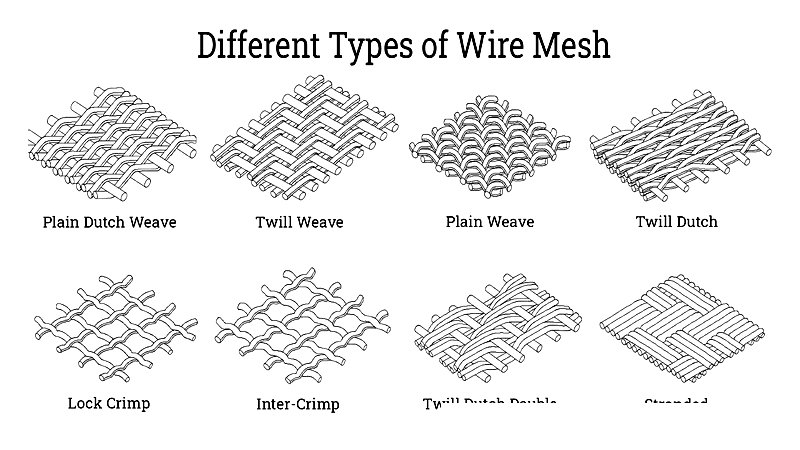

Wire mesh production involves either weaving or welding. Weaving resembles textile production on looms, while welding joins wires at their intersections. Both processes utilize automated, pre-configured machinery.

The Process of Wire Weaving

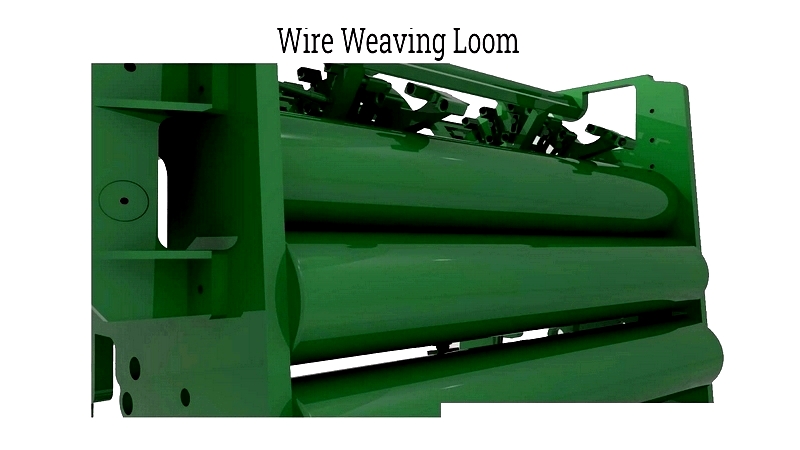

The demand for woven wire cloth increased significantly in the late 17th century due to its use in mining and pulp industries, leading to the development of specialized weaving looms. Over time, wire mesh applications expanded to include architecture, plastic extrusion, filtration, and aggregate screening, driving growth in the industrial wire weaving sector.

-

Weaving Loom — Mesh rolls are produced on looms with widths ranging from 48" to over 98". These looms feature a warp beam, heddle frames, a reed, a rapier for weft wire movement, and a take-up mechanism.

They produce both standard and custom mesh patterns, cut to customer specifications. Horizontally woven wires are called warp wires, while vertically woven wires are termed weft or shute wires, following textile terminology.

- Warp Beam — This cylindrical drum, wrapped with warp wires, requires precise tension control to prevent mesh elongation. The number of warp wires varies per mesh width but must maintain consistent length.

- Heddle frames — These frames separate wires from the warp beam. Most looms have two frames that alternately raise and lower warp wires as weft wires cross them.

- Rapier Band — The rapier carries weft wire across the loom width during each heddle frame cycle, inserting a single weft wire between warp wire sets.

- Reed — This component maintains warp wire spacing and pushes weft wire tightly into place after each insertion.

- Take-Up — A series of rollers guide finished fabric from the loom to a cloth roller, creating smooth, flat layers.

once set up, the weaving process becomes automated. The warp beam unwinds evenly while the take-up mechanism rolls the finished fabric, maintaining proper tension for high-quality production.

Welded Wire Mesh

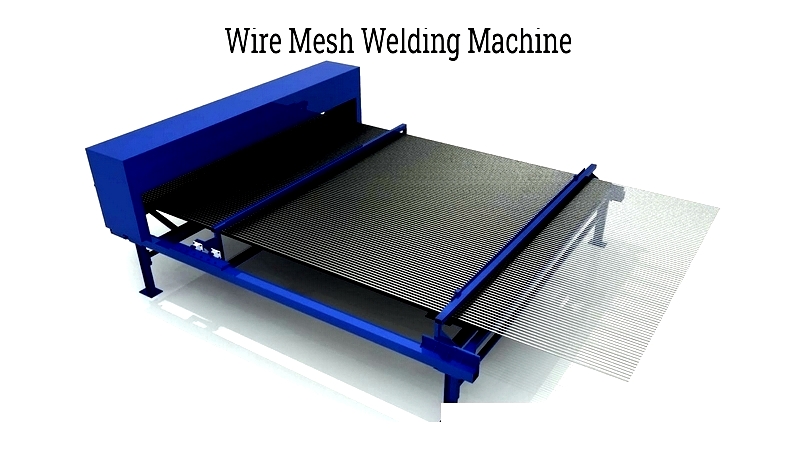

Welded wire mesh production involves a semi-automatic process where wire intersections are fused. Specialized machines apply uniform welds using techniques like resistance welding, TIG welding, plasma welding, and soldering.

- Weld Mesh Machine — Similar to weaving looms, this machine threads wires through its components.

- Wire Spools — Wires are straightened and pre-cut to mesh dimensions before being aligned on the welding surface.

- Mechanical Placement — Pre-cut wires are placed perpendicular to spool-fed wires, forming right angles.

- Welding — After alignment, the automated welding process begins, creating consistent welds at each intersection.

- Process Completion — Finished meshes are collected as rolls or sheets, trimmed, and bundled.

Welded mesh typically uses thicker wires for increased strength and durability. The welding process adds rigidity, making it ideal for fencing, cages, and concrete reinforcement.

Wire Mesh Varieties

Wire mesh types are classified by fabrication methods, characteristics, functions, and weave designs, tailored for specific strength, weight, and finish requirements. Key selection factors include metal type, mesh pattern, and finish.

Welded Wire Mesh

This type features square grids formed by welded wires, suitable for secure fencing, storage shelves, animal enclosures, room dividers, and pest traps.

Characteristics include:

- Resistance to environmental and weather changes

- Stable positioning that prevents shifting

- Customizable dimensions

Stainless steel welded mesh offers corrosion resistance and durability.

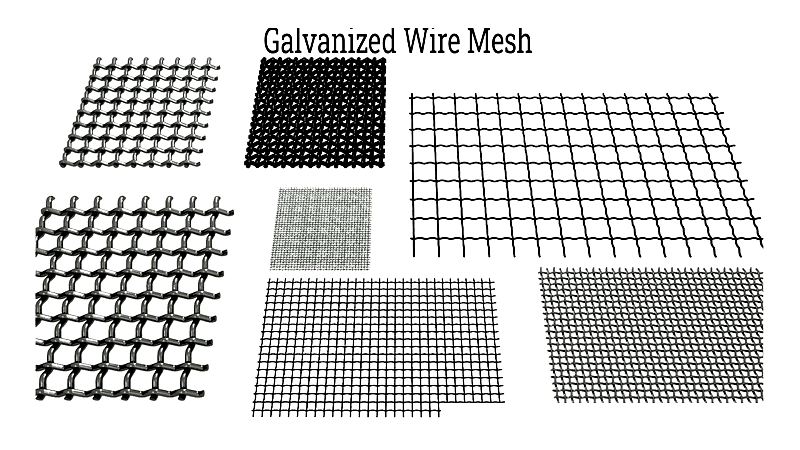

Galvanized Wire Mesh

Made from standard or carbon steel wire with a protective zinc coating, galvanized mesh resists rust and corrosion. Post-galvanization produces higher quality mesh at varying price points.

Applications include agricultural fencing, greenhouses, architectural uses, construction barriers, window guards, and infill panels. Its affordability makes it popular among wire mesh types.

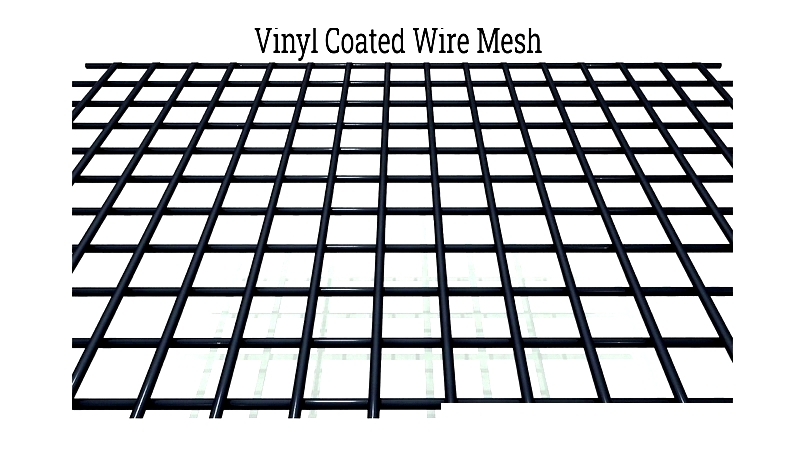

Vinyl-Coated Wire Mesh

Vinyl coating applied to woven or welded mesh creates a durable protective layer that withstands temperature variations, sunlight, and damage. It enhances appearance while providing rust and corrosion resistance, protecting against moisture and environmental factors.

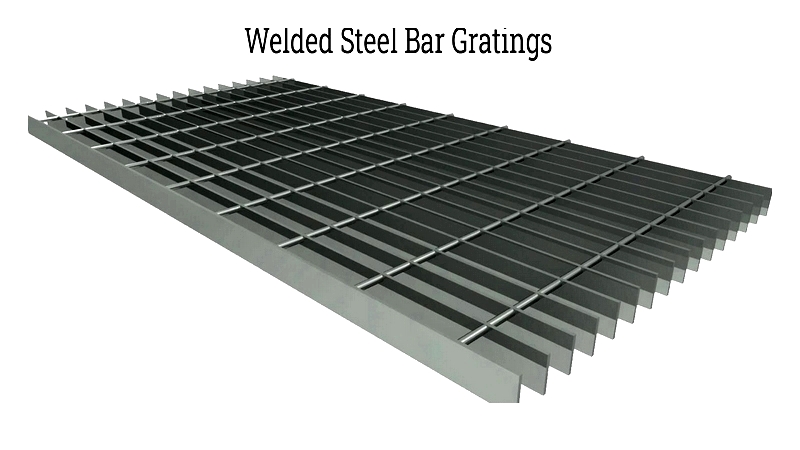

Welded Steel Bar Gratings

These gratings are forge-welded at high temperatures, bonding vertical and horizontal bars for strength and stability. Made from carbon or stainless steel, they're ideal for heavy-duty applications like ramps, bridge decking, ventilation grilles, and industrial flooring.

Panels typically measure 2-3 feet in width and 2 feet in length, with bar depths from 1" to 6" and thicknesses between 0.25" to 0.50".

Stainless Steel Wire Mesh

Known for quality, stainless steel mesh offers excellent performance. Chromium content provides oxidation resistance, making it suitable for outdoor applications.

Available in welded or woven forms, it's valued for reliability, corrosion resistance, and suitability for marine environments.

Common grades include 304, 304L, 316, 316L, 321, 347, and 430, with wire diameters from 0.0085" (0.216 mm) to 0.307" (7.8 mm). Mesh with openings under 0.25" (6.35 mm) is called wire cloth