Introduction

This article provides an in-depth exploration of adjustable work benches.

You will learn about various topics including:

- What is an Adjustable Work Bench?

- Types of Adjustable Work Benches

- Uses for Adjustable Work Benches

- Materials Used to Construct Adjustable Work Benches

- And much more...

Chapter One – What is an Adjustable Work Bench?

An adjustable work bench is a versatile tool that allows users to modify the work surface height for improved ergonomics and comfort. This functionality ensures tasks can be performed safely and efficiently. Various types exist, with some capable of supporting over a ton and featuring automatic height adjustment to match user preferences.

Employers prioritize workplace safety and efficiency by investing in adjustable work benches to reduce discomfort and prevent strain. These benches help alleviate muscle tension and minimize work-related injury risks.

Work surfaces can be customized with materials like steel, plastic, or wood to suit specific needs. Adjustment mechanisms range from manual hand cranks to advanced remote-controlled systems.

Modern innovations include computer workbenches with integrated power outlets and organizational features. Ergonomic designs are particularly valuable in industries requiring small part assembly or inspection, as they reduce strain from prolonged static positions.

The growing emphasis on ergonomics and the negative impacts of poor working postures have led HR professionals and production managers to seek ergonomic solutions. Manufacturers now focus on creating benches with application-specific features that enhance both worker comfort and operational efficiency.

Chapter Two – Types of Adjustable Work Benches

Industrial, commercial, and laboratory environments require specialized equipment that meets specific application needs and workforce ergonomics. This has driven widespread adoption of adjustable workbenches, valued for their versatility, customization, and adaptability across various settings. From manufacturing to education, properly selected adjustable height workbenches can enhance productivity, safety, and comfort.

These workbenches come in diverse styles categorized by surface material, adjustment mechanism, connectivity, weight capacity, and suitability for specialized environments. With workplace health and efficiency as priorities, manufacturers continue innovating to deliver custom, ergonomic solutions that support modern workflows.

Adjustable Work Bench Types

Portable Work Benches

Portable adjustable workbenches are designed for mobility in dynamic environments like field service operations or workshops. Featuring durable casters or locking wheels, they enable easy transportation between locations. Adjustment mechanisms may include hydraulic actuators, manual cranks, or electric motors for effortless height changes.

Mobile benches often use compact hydraulic lifts or manual crank systems, with advanced models incorporating smart controls for preset height settings.

Plain Adjustable Work Bench

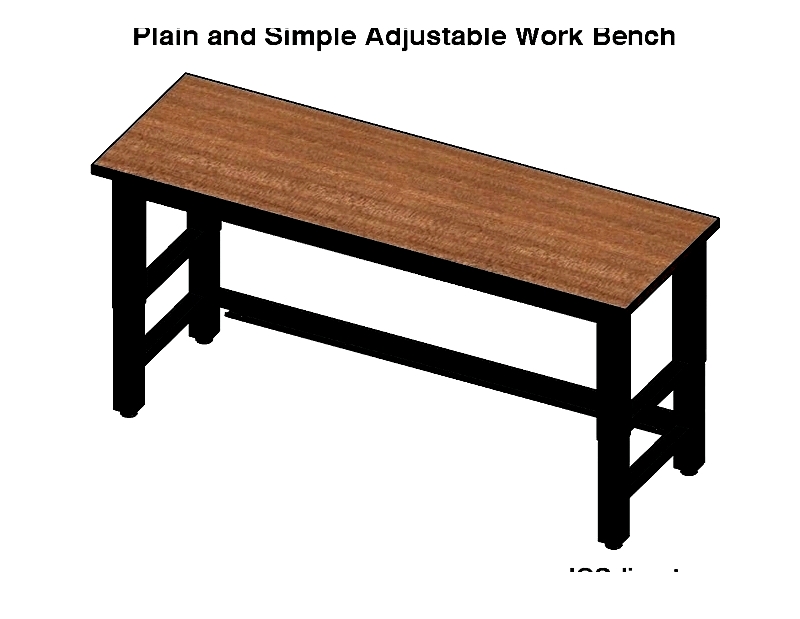

Plain adjustable height workbenches provide durable solutions for heavy-duty applications. Using steel legs with locking pins, they offer manual height adjustment without complex mechanisms. This simple design ensures reliability and strength for environments like metalworking or manufacturing.

Available in standard sizes, these benches feature reinforced frames for stability during rigorous use.

Scientific Workstations

Ergonomic laboratory workbenches are essential for research settings, offering height adjustment via electric, manual, or pneumatic systems. These workstations provide stability and often include features like modular shelving or chemical-resistant surfaces for specialized applications.

Heavy Duty Work Benches

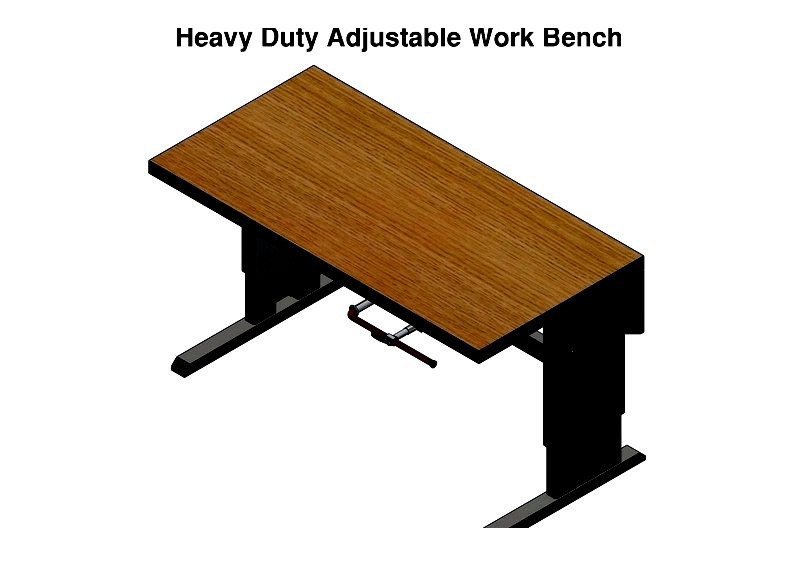

Heavy-duty adjustable workbenches are built for demanding environments, featuring robust adjustment mechanisms and high weight capacities. They often include interchangeable surfaces and additional features like under-bench storage.

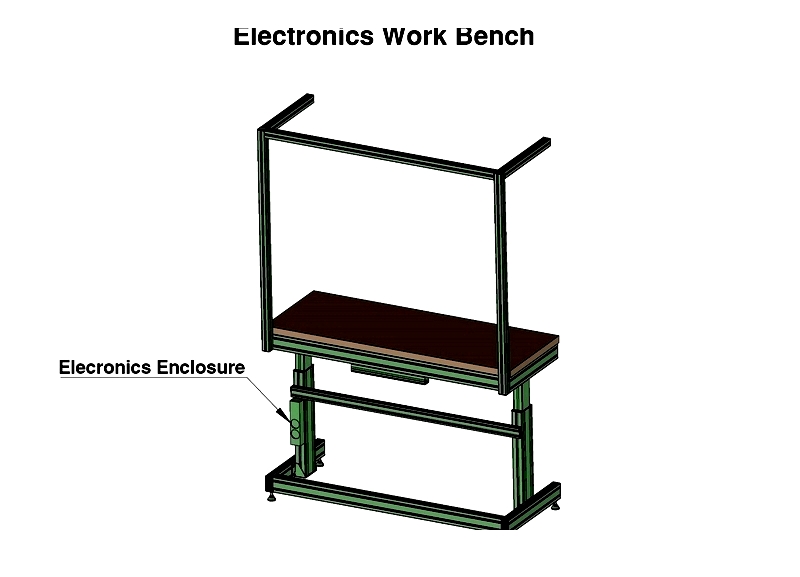

Benches for Electronics

ESD-safe electronic workbenches provide ergonomic positioning and static protection for sensitive components. Features often include integrated power outlets, tool storage, and cable management systems.

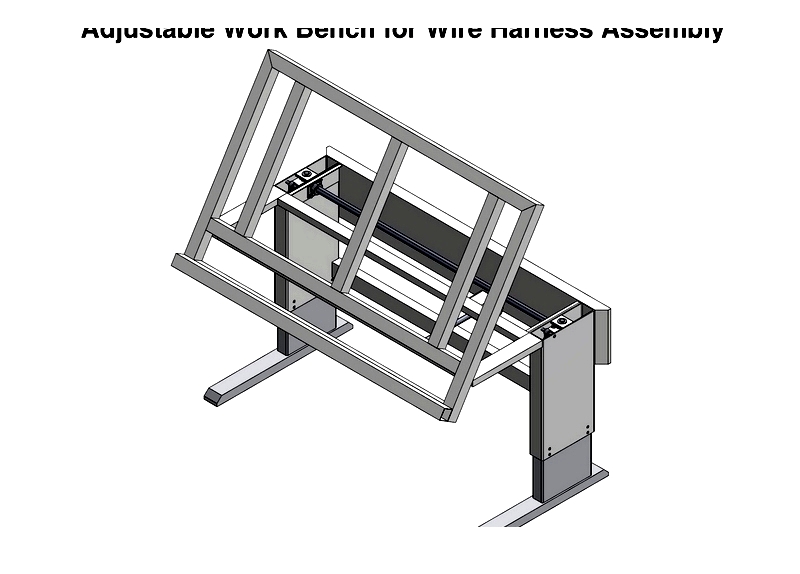

Wire Harness Assembly Benches

Specialized benches for wire harness assembly feature adjustable and tilting surfaces for improved ergonomics. They may include grid layouts, fixture points, and integrated lighting for efficient assembly.

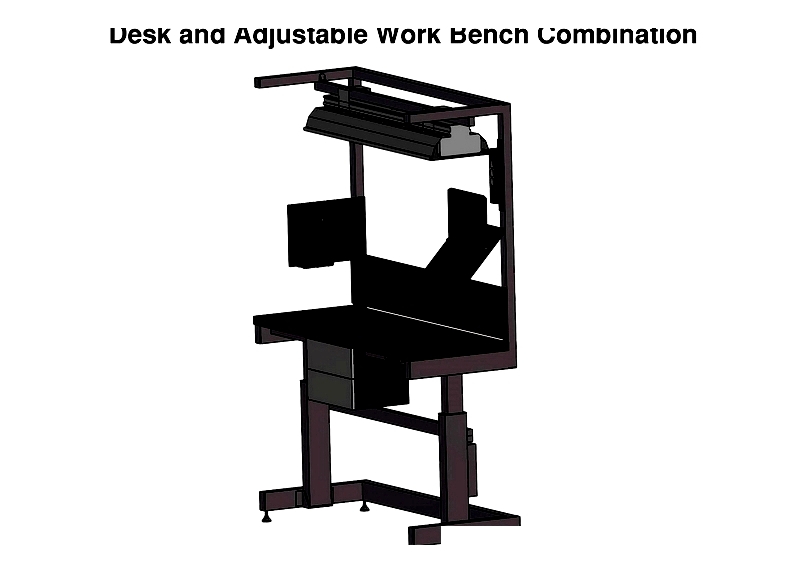

Desk and Work Bench

Desk-workbench hybrids combine office functionality with industrial strength, featuring height adjustment and ample storage. These versatile solutions suit environments requiring both administrative and technical workspaces.

Electrostatic Discharge (ESD) Adjustable Work Bench

ESD workbenches protect sensitive electronics with static-dissipative surfaces and integrated grounding. They are essential for electronics manufacturing and repair environments.

Computer Work Bench

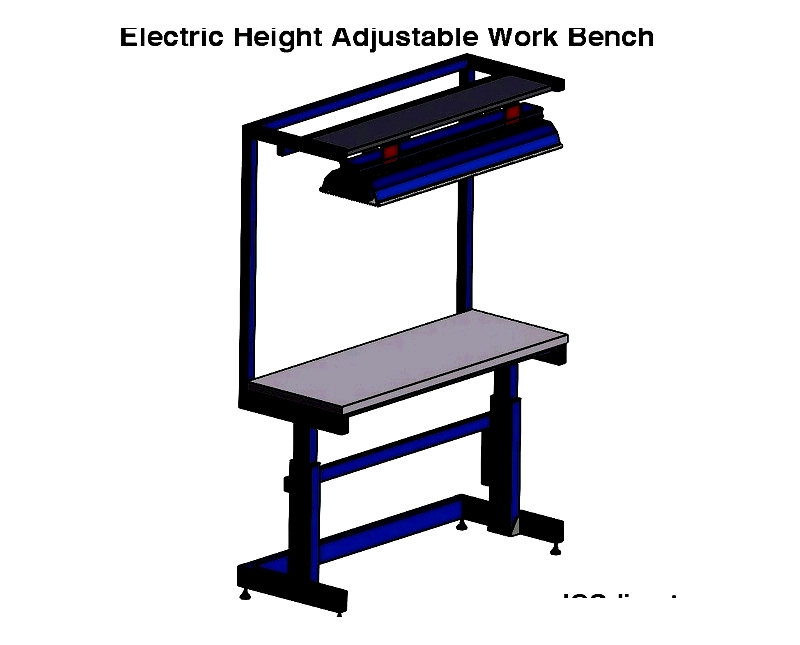

Adjustable computer workbenches accommodate technology needs with features like monitor mounts, cable management, and ergonomic designs. They support both sitting and standing positions for improved comfort.

Vibration Isolation Work Benches

Vibration isolation workbenches use damping technologies to protect precision work. They are crucial for applications requiring stability, such as microscopy or semiconductor fabrication.

The diverse range of adjustable workbenches available today addresses modern workplace challenges through ergonomic design and specialized features. Selecting the appropriate workbench tailored to specific needs is key to enhancing productivity and ensuring worker well-being.