Introduction

This article offers a comprehensive overview of shot peening equipment.

You will discover:

- The definition of Shot Peening Equipment

- Various types of Shot Peening Equipment

- The working principle of Shot Peening Equipment

- Manufacturing processes of Shot Peening Equipment

- Different Shot Peening Media

- And more…

Chapter 1: Understanding Shot Peening Equipment

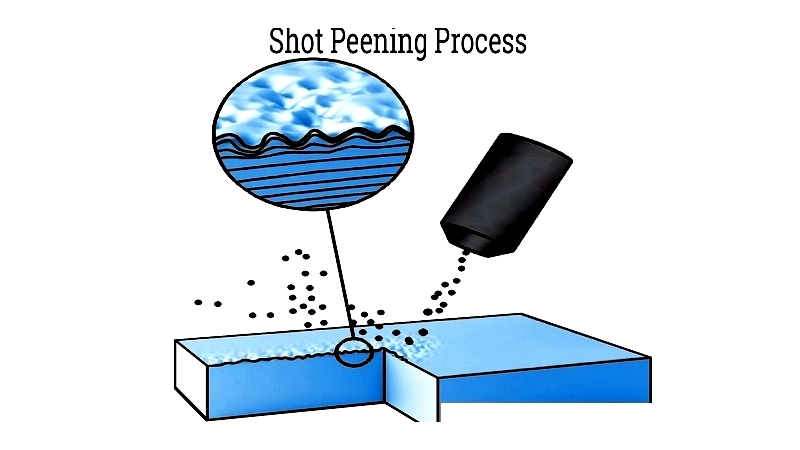

Shot peening equipment consists of specialized machines designed to propel concentrated peening media onto surfaces with high force. This process modifies or prepares components for various applications. The technique employs multiple methods including centrifugal wheel, ultrasonic, wet, and laser peening, though some approaches don't use traditional peening media.

The peening media, called shot, comes in various materials depending on equipment type and the treated material. Common options include steel, glass, and ceramic. Media selection depends on its specific characteristics. Upon impact, the media creates compressive stresses that form small indentations, compressing the underlying material.

As a cold working process, shot peening alters component mechanical properties by generating surface compressive stress. This enhances component strength while optimizing stress distribution. It extends service life by improving resistance to fatigue, corrosion, cavitation erosion, and cracking. The required compressive stress level varies with peening media intensity and coverage.

Available shot peening equipment types include:

- Industrial shot peening machines

- Laser ablation peeners

- Ultrasonic needle peening tools

- Flap peeners

- Peen markers

- Shot peeners

- Dry shot peening cabinets

- Wheel shot peening machinery

- Micro shot peeners

- Shot peening rooms

- Shot peening cabinets

- Air shot peeners

- Airless shot peeners

- Portable shot peeners

- Wet shot peeners

- Micro dimpling equipment

- Peen formers

- Peening machines

Chapter 2: Types of Shot Peening Equipment

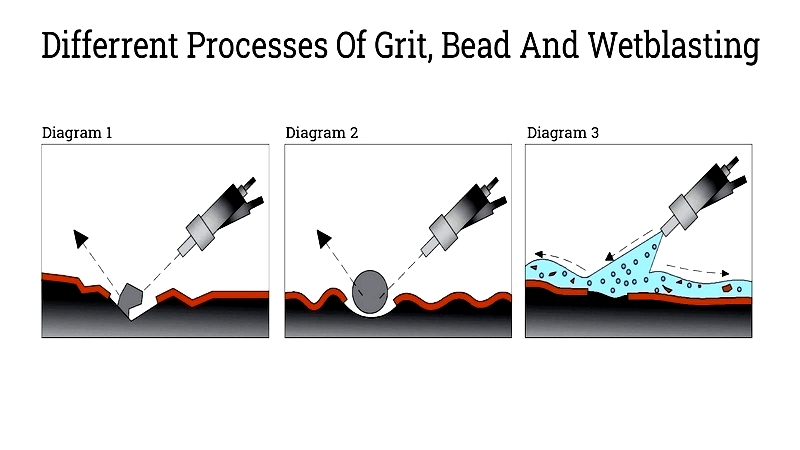

As a core element in surface engineering and metal finishing industries, shot peening equipment uses round media rather than sharp abrasives found in sandblasters. Unlike abrasive blasting, it specifically enhances metal fatigue resistance rather than just cleaning surfaces. Available media ranges from natural materials to durable plastics, glass beads, steel shot, aluminum oxide, and silicon carbide - each offering unique hardness and impact characteristics for aerospace, automotive, defense, and heavy manufacturing applications. Media sizes are measured in mesh or microns, influencing peening intensity and coverage.

When shot media impacts surfaces, particles gradually break down, reducing impact force and effectiveness. Operators must monitor media condition and replenish as needed to maintain consistent compressive stress and peening quality. Effective shot peening requires balancing media size, material, freshness, and impact velocity.

Unlike abrasive blasting that cuts materials, shot peening uses round shot to elastically deform surfaces. This controlled deformation creates uniform dimples, inducing beneficial compressive stresses that improve fatigue strength, crack resistance, and service life - particularly for critical components like gears, springs, and turbine blades.

While similar in configuration, shot peening and sand blasting serve different purposes. Sand blasting removes surface material for cleaning or coating preparation, while shot peening enhances surfaces by minimizing crack propagation and relieving tensile stresses without significant material removal. Notably, sand blasting generates more dust and spent abrasive, posing greater health and environmental challenges.

Modern shot peening equipment uses pneumatic, hydraulic, or centrifugal force to accelerate media at controlled velocities. Proper peening intensity and uniform coverage maximize surface compressive stress and component durability. Unlike plating or welding, shot peening improves metal fatigue strength through a non-chemical, minimal-waste "green" process.

Shot Peening Equipment Processes

Contemporary shot peening technologies employ various mechanical and physical energy forms to impart controlled surface impacts. Key processes include:

- Air Shot Peening

- Cavitation Peening

- Centrifugal Wheel Shot Peening

- Hammer Peening

- Laser Ablation Peening

- Peen Marking

- Powder Impact Plating

- Rotary Flap Peening

- Shot Peen Forming

- Ultrasonic Needle Peening

- Ultrasonic Shot Peening

- Wet Shot Peening

Among these, conventional mechanical methods like air, wet, and wheel shot peening remain most prevalent in commercial manufacturing and maintenance sectors.

Pneumatic or Air Shot Peening Equipment

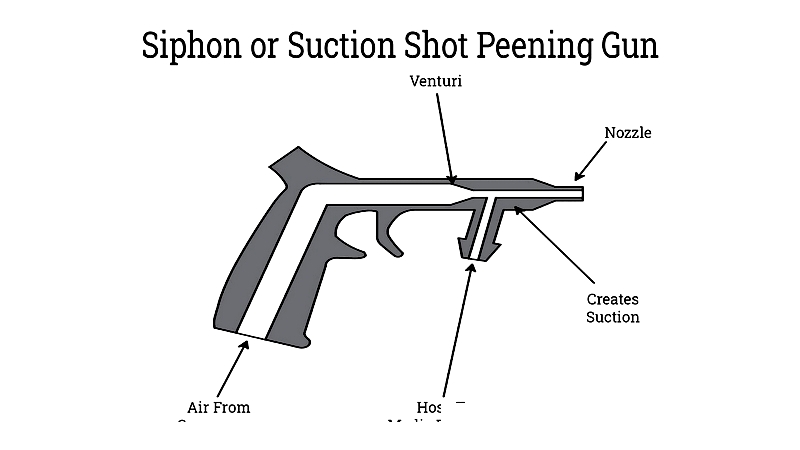

Air/Dry Shot Peening Equipment – These systems use pressurized air to accelerate shot media onto target surfaces. Divided into suction and direct pressure types, pneumatic systems offer flexibility for precision treatment in aerospace, medical, and automotive applications.

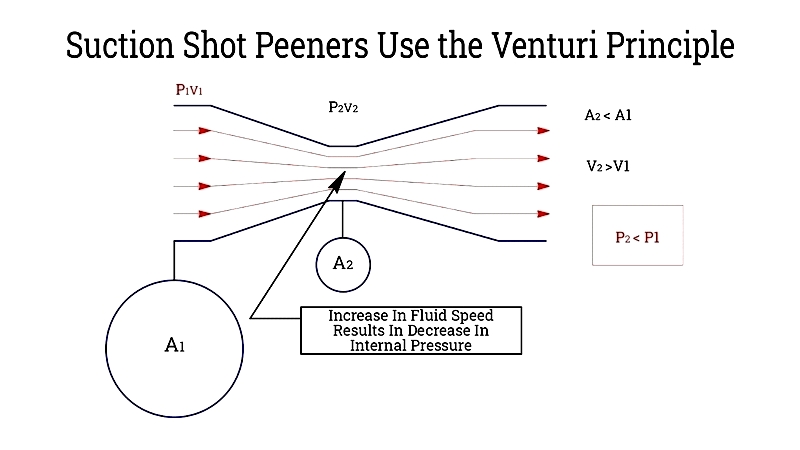

Suction Shot Peening Equipment – Typically installed in cabinets, these systems employ the Venturi effect to introduce abrasives into high-speed streams. This efficient method suits low-volume production and maintenance settings.

Venturi systems find wide industrial use for vacuum creation in clamping and material transfer applications.

Suction peening setups are cost-effective for small shops but require higher air pressures for heavier media. Their gentler approach benefits delicate parts and prototype work, though with longer cycle times than pressure systems.

Reduced aggressiveness extends component lifespan, lowering operational costs for less intensive applications.

Gravity-feed variants use a shot reservoir above the gun, with gravity assisting media delivery.

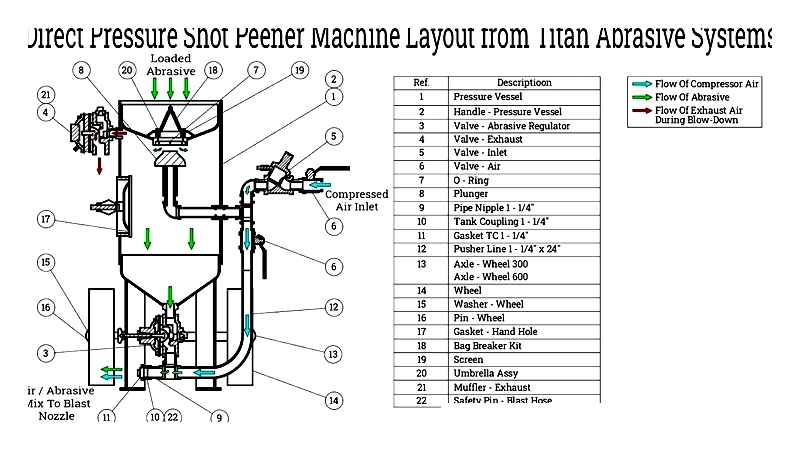

Direct Pressure Shot Peening Equipment

These systems use pressurized vessels to accelerate media through blast hoses and specialized guns. ASME-certified pressure vessels ensure safety and consistent performance.

Direct pressure systems offer precise control for aerospace and automotive applications. Adjusting nozzle size, air pressure, and flow rate tailors impact energy and coverage to material requirements. The kinetic energy formula (K = ½mv²) ensures targeted delivery and uniform stress distribution.

With greater impact force and throughput, direct pressure systems outperform suction units in speed and consistency. They effectively handle dense media like steel shot, making them ideal for high-volume production and automated cells where reliability is critical.

These systems require commercial-grade compressors to sustain high mass flow rates. Multiple blast nozzles can optimize coverage and process speed.