Introduction

This article provides comprehensive guidance on selecting and specifying stainless steel tanks. Continue reading to explore:

- Why choose stainless steel for storage tanks?

- Types of stainless steel tanks

- Available stainless steel tank finishes

- Common storage tank applications

- And more...

Chapter 1: What are Stainless Steel Tanks?

Stainless steel tanks serve diverse industries including food, beverage, dairy, pharmaceuticals, and cosmetics where hygiene and purity are paramount. These tanks also play vital roles in industrial settings for storing chemicals and gases, requiring exceptional durability against chemical degradation. This durability stems from their composition - stainless steel is an iron alloy containing chromium that enhances corrosion resistance. A protective oxide layer forms naturally, shielding the metal from harmful substances.

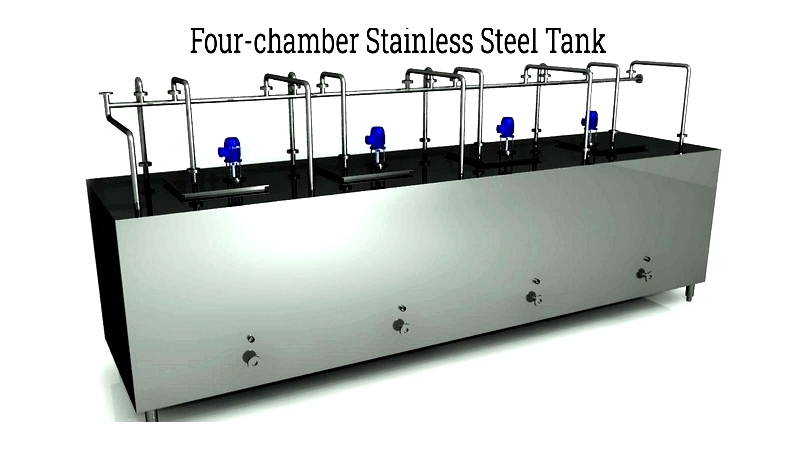

Available in various forms and sizes, stainless steel tanks come in both vertical and horizontal configurations to accommodate space and logistical requirements. Their capacity ranges from compact designs holding just a few liters to large-scale tanks capable of storing thousands of gallons. Basic residential water tanks typically feature an inlet, outlet, and manhole, while industrial versions include multiple nozzles for liquid/gas blending and monitoring equipment. Some tanks function as reactors or mixers, equipped with agitators and mixing mechanisms. Many feature cooling jackets and double walls for temperature control and insulation. The versatility of stainless steel tanks allows for easy customization to meet specific application needs.

What Makes Stainless Steel Corrosion Resistant?

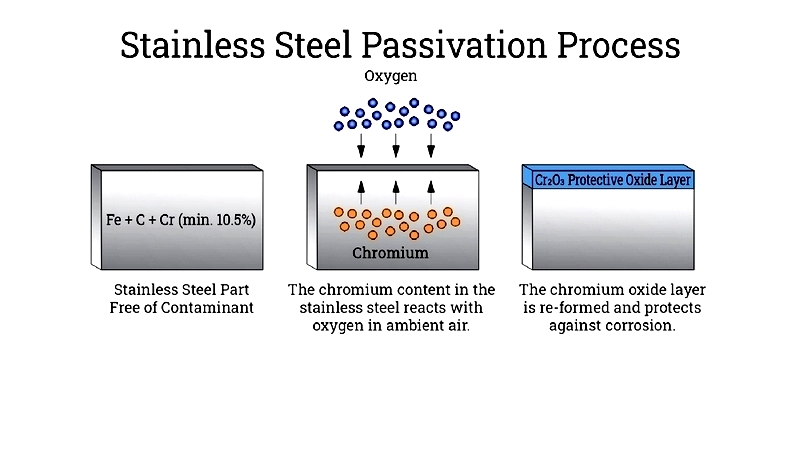

Stainless steel achieves corrosion resistance through passivation, a process that renders the metal largely inert to oxidation. This occurs through the formation of a protective oxide coating on its surface. The passive layer, primarily composed of chromium oxides, shields the steel from aggressive environmental factors and processing fluids.

The primary component of stainless steel is iron, combined with at least 10.5% chromium which enables protective oxide film formation. Additional alloying elements include carbon, nickel, manganese, and molybdenum. Carbon strengthens the steel, while nickel and manganese stabilize the austenitic structure, maintaining ductility at high temperatures. Austenitic stainless steel retains toughness even when cold. Manganese serves as a cost-effective alternative to nickel, though less efficient. Molybdenum enhances corrosion resistance and high-temperature strength, though it may cause brittleness - a drawback mitigated by increased nickel content.

Passivation

Passivation involves exposing stainless steel to air, allowing oxide layer formation. Chemical treatments accelerate this process by immersing the steel in acidic solutions (typically nitric acid) that thoroughly clean the surface. This removes contaminants like free iron that might interfere with passive layer formation. After acid treatment, the metal undergoes neutralization with sodium hydroxide solution. Descaling further removes oxides that may form during high-temperature processes like welding or heat treatment.

Chapter 2: What are the different stainless steel grades used in tanks?

Stainless steel is the preferred material for storage, process, mixing, and chemical tanks due to its exceptional corrosion resistance, durability, and strength under demanding conditions. Stainless steel tanks utilize various grades, each offering distinct characteristics tailored for specific applications, chemical compatibility, and performance requirements. Proper grade selection ensures tank longevity, hygiene, and maintenance efficiency across industries like pharmaceuticals, food processing, water treatment, dairy, and chemical manufacturing. This section examines the most commonly used stainless steel grades for tank fabrication: 304/304L, 316/316L, and duplex.

Stainless Steel 304 and 304L

Stainless steel 304 contains 18-20% chromium, 8-11% nickel, and 2% manganese. As the most common stainless steel grade, it offers sufficient corrosion resistance for most applications at a lower cost than other grades. Its austenitic structure provides excellent ductility for forming various products.

304L stainless steel maintains similar chromium, nickel, and manganese content but features reduced carbon to prevent sensitization. Sensitization occurs when chromium and carbon form carbides at high temperatures, depleting chromium available for passive film formation - particularly at grain boundaries. This reduction in carbides preserves corrosion resistance in high-temperature applications.

The combination of affordability and reliable performance makes 304/304L ideal for general-purpose storage applications including potable water, breweries, distilleries, and food-grade installations. Their ease of fabrication makes them popular for cylindrical tanks, jacketed tanks, and atmospheric tanks where aggressive chemical resistance isn't required.

Stainless Steel 316 and 316L

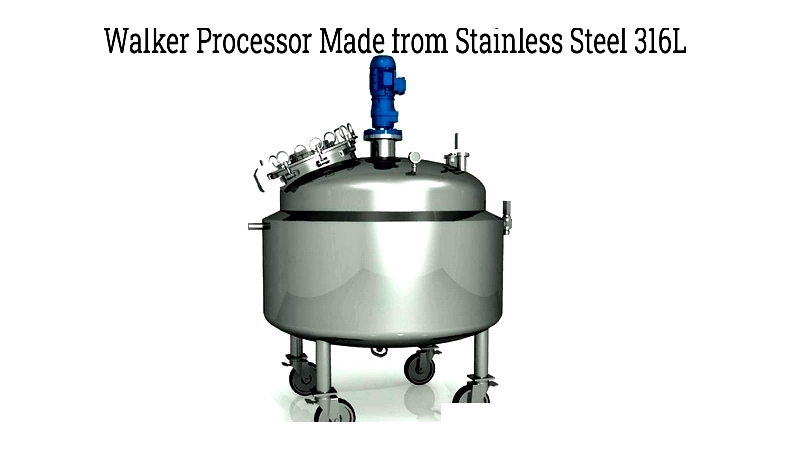

316 stainless steel contains 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and 2% manganese. The added molybdenum enhances corrosion resistance compared to 304. Increased nickel content counteracts molybdenum's ferritic-forming properties. Like 304L, 316L features reduced carbon content for high-temperature applications.

316/316L tanks excel in resisting pitting and crevice corrosion from chlorides, acids, and harsh chemicals. They're preferred for industrial process tanks, chemical storage, offshore applications, brine tanks, and saltwater environments. Industries requiring hygienic tanks - pharmaceuticals, food processing, cosmetics, and biotechnology - often specify 316L for its purity, cleanability, and contamination resistance.

When choosing between 316 and 316L for tank manufacturing, consult suppliers who can evaluate application requirements, temperature, chemical concentration, and relevant industry standards (ASME, FDA, or 3-A) to recommend the optimal grade.

Duplex Stainless Steel

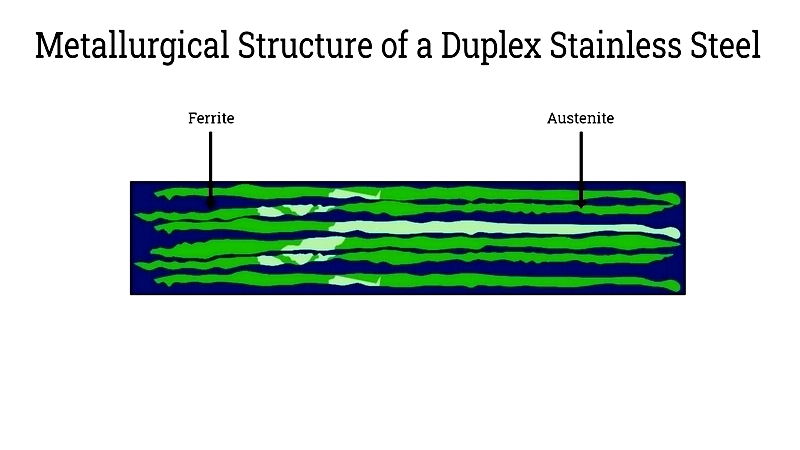

Duplex stainless steel combines austenitic and ferritic structures. While austenitic steel offers superior corrosion resistance and mechanical properties, it's more susceptible to stress corrosion cracking. Ferritic steel resists such cracking. The duplex combination enhances resistance to stress corrosion cracking, making it ideal for chloride-rich environments like water applications.

For demanding industrial uses, duplex stainless steel tanks balance strength with resistance to aggressive chemicals including chlorides and sulfides. Their superior mechanical strength allows reduced wall thickness without compromising performance. These tanks suit wastewater treatment, desalination plants, oil/gas storage, pulp/paper processing, and chemical reactors. The duplex structure extends service life, reduces corrosion-related failures, and improves safety in harsh environments.

Duplex stainless steel contains 20-28% chromium, 2-5% molybdenum, and 5-8% nickel. Increased chromium and molybdenum content enhances corrosion resistance and mechanical strength. Compared to 316, duplex steel offers cost savings through lower nickel content and higher strength at reduced thickness. The most common duplex grade is 2205 stainless steel.

When selecting tank materials, consider chemical resistance requirements, temperature ranges, pressure ratings, and compliance with food-grade or sanitary standards. Reputable stainless steel tank manufacturers can help compare 304 vs. 316 stainless steel or duplex