Introduction:

This article provides a comprehensive guide to springs. Continue reading to learn about the following topics:

- What Are Springs?

- Overview of Spring Design

- Types of Springs

- Common Spring Materials

Chapter One – What Are Springs?

Springs are versatile mechanical devices that store energy when subjected to tensile, compressive, bending, or torsional forces. When deflected, they accumulate energy while generating an opposing force. The relationship between deflection and force depends on the spring's specific characteristics. The most common type is the cylindrical helical spring, made from round wire wound into a cylindrical shape with uniform pitch. This design is widely used in vehicle suspensions, engine valves, dampers, and other applications.

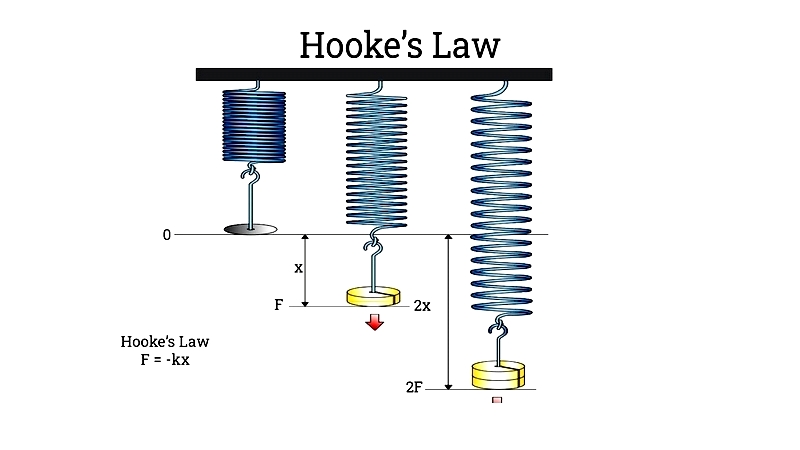

Springs and Hooke's Law

Hooke’s Law describes spring behavior, stating that the force applied is directly proportional to deflection within the elastic limit. The force (F) can be calculated by multiplying displacement by the spring rate.

F = -kx

Here, (k) represents the spring rate, and (x) is the extension or compression distance. The negative sign indicates the spring force opposes the applied force direction.

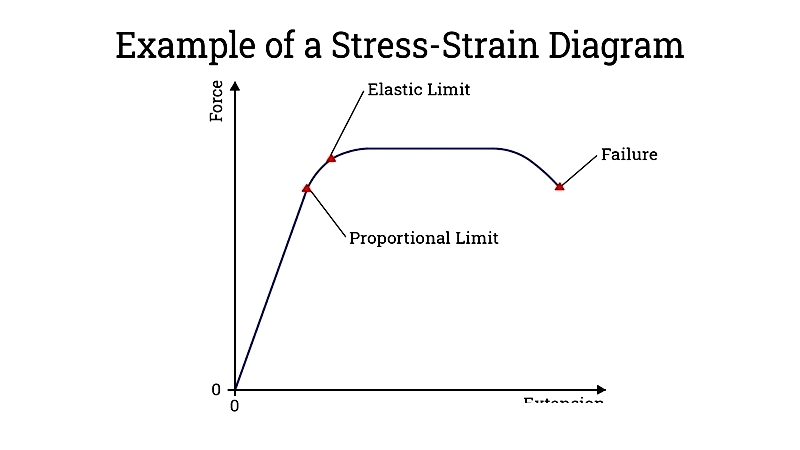

For a given spring cross-section, force can be converted to stress, while deflection becomes strain. Hooke's Law thus shows a direct stress-strain relationship, represented by Young's modulus. This intrinsic material property helps model spring behavior, while the spring constant, influenced by length, is an extrinsic property.

Note that Hooke's Law applies only up to the proportionality limit. Beyond this elastic limit, the linear stress-strain relationship breaks down, causing permanent deformation when stress is removed.

Chapter Two – Overview of Spring Design

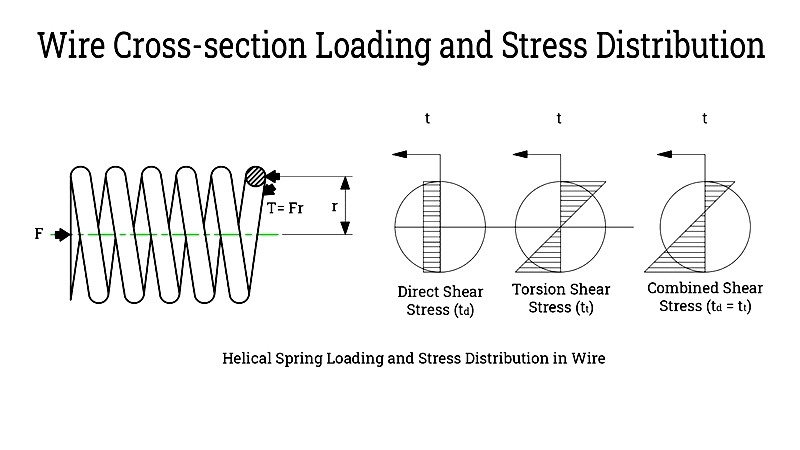

Understanding spring design fundamentals is essential for engineers developing mechanical systems where performance and reliability matter. Springs operate through torsion or shear forces causing dimensional changes. Visualize unwinding a helical spring into straight wire—typically with a round cross-section—to see how shear forces act across the wire, affecting energy storage and release.

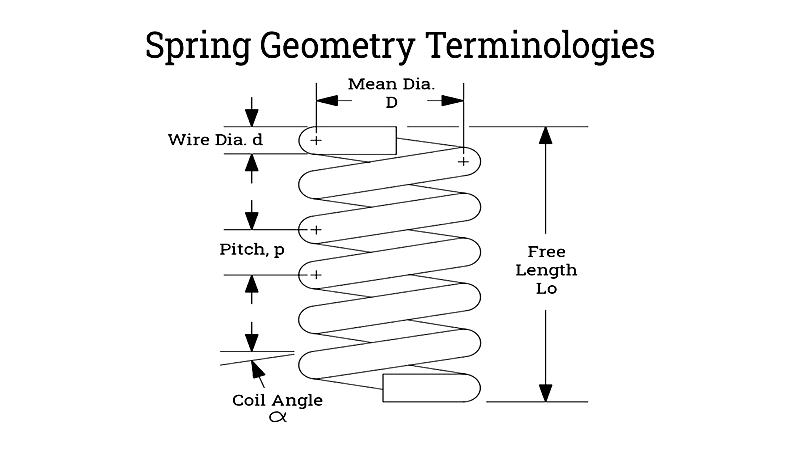

When wound into a helix, curvature effects create varying shear strains between inner and outer coil layers, resulting in non-uniform stress distribution. The wire cross-section experiences both torsional and direct shear. To model spring behavior accurately, engineers use the Wahl correction factor, which accounts for stress concentrations in coiled geometry, preventing spring failure under load.

τ = Kw 8FD ⁄ d³

Kw = 4C - 1 ⁄ 4C - 4 + 0.615 ⁄ C

Here, F is the load, D is the mean coil diameter, d is the wire diameter, Kw is the Wahl factor, and C is the spring index (C = D/d). These variables are crucial for custom spring design and compression spring engineering.

The spring's elongation (x) is technically called linear deflection (δ). Spring deflection calculations derive from torsion mechanics, specifically angular displacement (θ):

θ = TL ⁄ GJ

Where T is torque, L is wire length, G is shear modulus, and J is polar moment of inertia. For cylindrical springs, linear deflection is:

δ = 8FC³N ⁄ Gd

Here, N is active coils. This relationship yields the spring rate (k), representing force per unit deflection:

k = F ⁄ δ = Gd ⁄ 8C³N

Spring rate selection and deflection analysis are vital in automotive, aerospace, and electronics, where spring performance impacts system efficiency. Designers must know applied force and spring length, considering installed (preload) and operating (maximum load) conditions.

The spring design process begins with material selection—high-carbon steel, stainless steel, or alloys—based on strength, corrosion resistance, and fatigue life. Initial calculations for wire diameter, coil diameter, and active coils are compared against standards. Spring design software aids this stage. After establishing trial values, stress verification ensures theoretical stress doesn't exceed material limits. If not, parameters are adjusted for optimal spring performance.

These equations apply to cylindrical helical springs with constant pitch and round wire. Conical, barrel, and leaf springs require different methodologies.

Comprehensive spring engineering also considers:

- Spring end types (ground, squared, or open)

- Buckling risk for long springs

- Fatigue life under cyclic loading

- Vibration and surging effects

- Corrosion protection for harsh environments

- Industry standard compliance (ASTM, ISO)

Optimizing spring selection through analysis, material choice, and manufacturer collaboration ensures durability and reliability in industrial, automotive, and medical applications.