Introduction

This guide covers all essential aspects of contract sewing.

You'll discover:

- The definition of contract sewing

- Common applications of contract sewing

- Materials processed through contract sewing

- Industries utilizing contract sewing services

- Additional valuable information

Chapter One – Understanding Contract Sewing

Contract sewing is a specialized manufacturing service that produces diverse products using skilled workers and advanced equipment. This sector excels in delivering sewing solutions for soft goods across multiple industries including medical, military, apparel, aerospace, and custom clothing.

The contract sewing process requires greater complexity and precision than conventional sewing. Success depends on careful project planning and execution, with emphasis on quality and efficiency.

Contract sewers are professionals who assist manufacturers with small-scale projects, typically under 100 units. Their expertise in various sewing techniques enables them to create garments and complex items.

Contract sewing accommodates diverse materials including vinyl-coated nylon, neoprene, Hypalon, canvas, anti-static fabrics, cotton, polyester, felt, plastic, webbing, and leather. Products are manufactured according to client specifications.

Chapter Two – Applications of Contract Sewing

Contract sewing plays a vital role in modern manufacturing, offering scalable textile solutions for businesses lacking in-house capabilities. This industry developed to meet demand for custom sewn goods that manufacturers couldn't efficiently produce themselves.

Companies outsource to contract sewing specialists who serve as production partners. These providers combine technical expertise, skilled labor, and industrial equipment to deliver high-quality textile products. From prototypes to mass production, contract sewing helps businesses launch products quickly and meet market demands.

The industry serves diverse sectors including automotive, aerospace, safety, medical, and industrial markets. Clients often operate in fields where sewing isn't their core competency, relying on experts for fabric assembly and precision sewing.

Contract sewing transforms concepts into finished products through close collaboration. Providers deliver sewn goods that meet strict quality, durability, and safety standards.

Contract Sewing Applications

Contract sewing excels in high-volume production with fast turnaround, handling items of any size or complexity. Beyond clothing, industrial sewing solutions utilize specialized materials and automated technologies to create durable products for various industries.

- Automotive textiles for upholstery and safety systems

- OEM textile assemblies for industrial and consumer goods

- Custom protective gear and medical textiles

- Prototype development and volume manufacturing

Automotive Upholstery

Automotive fabrics require durability and UV resistance. Specialized equipment meets OEM standards for seats, headliners, and trim. Materials range from leather to technical fabrics, matched to specific applications.

Airbag Production

Airbag manufacturing demands precision sewing of dense fabrics. Special techniques create secure seams meeting safety regulations, with rigorous testing ensuring reliability.

Protective Knee Pads

Knee pads combine impact-resistant materials with reinforced stitching. Designed for comfort and durability, they withstand harsh work conditions.

Industrial Aprons

Aprons made from leather, rubber, or specialty textiles protect against workplace hazards. Custom options cater to food processing, welding, and other industries.

Luggage Manufacturing

Durable materials like ballistic nylon are precision-cut and stitched into travel bags and cases. Services may include logo embroidery and RFID integration.

Aviation Seatbelts

Airplane seatbelts use high-tensile webbing and robust buckles. Each unit undergoes testing to withstand 16G forces, meeting aviation safety standards.

High-Visibility Safety Apparel

HVSA garments meet ANSI standards for visibility. Contract sewing ensures compliance through retroreflective tape application and performance fabric integration.

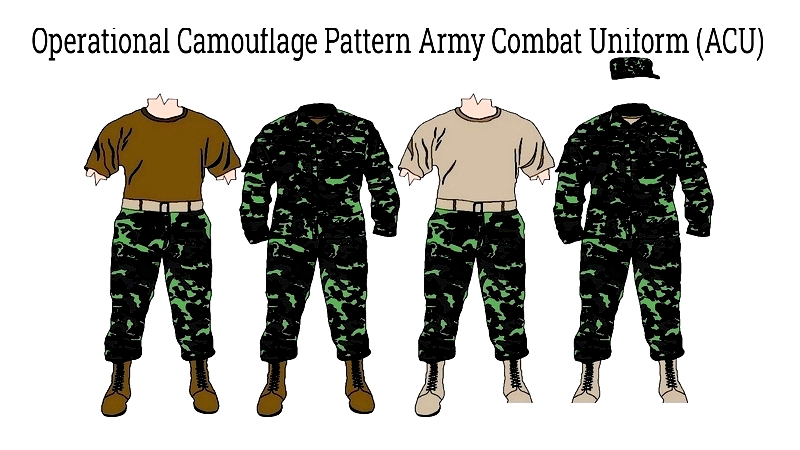

Professional Uniforms

Uniforms employ tactical fabrics for durability and functionality. Production meets NFPA or OSHA standards as required for specific industries.

Seating Solutions

Contract sewing produces durable upholstery for office and public seating. Components are tailored for comfort and longevity in heavy-use environments.

Industrial Curtain Systems

Technical textiles create curtains for noise reduction and workspace separation. Features include reinforced hems and snap fasteners for industrial applications.

Aerospace Textiles

Space suits and insulation blankets use advanced materials like coated nylon. Products undergo rigorous testing for extreme conditions.

Medical Textile Products

Healthcare sewing produces sterile gowns, drapes, and patient care items. Antimicrobial fabrics meet regulatory requirements, with strict quality control.