Introduction:

This guide covers everything you need to know about industrial shredders and their applications.

You'll discover:

- What industrial shredders are

- The various designs of industrial shredders

- How industrial shredders operate

- Materials suitable for shredding

- And much more...

Chapter One – What is an Industrial Shredder?

Industrial shredders are powerful, versatile machines designed to process both dense and lightweight materials for recycling or disposal. These environmentally beneficial machines convert unusable materials into formats suitable for remanufacturing or efficient waste management.

Ranging from compact office units for document destruction to large commercial models for recycling, industrial shredders have become essential in manufacturing sectors. They significantly reduce waste volumes sent to landfills.

Chapter Two – Different Industrial Shredder Designs

Industrial shredders play vital roles in recycling, waste management, and materials processing. They handle diverse materials from paper and cardboard to plastics, tires, and metals. Professionals can choose from single, double, or four-shaft configurations, each offering unique capabilities. These machines use electric motors for efficiency or hydraulic systems for heavy-duty operations.

Industrial Shredder Designs

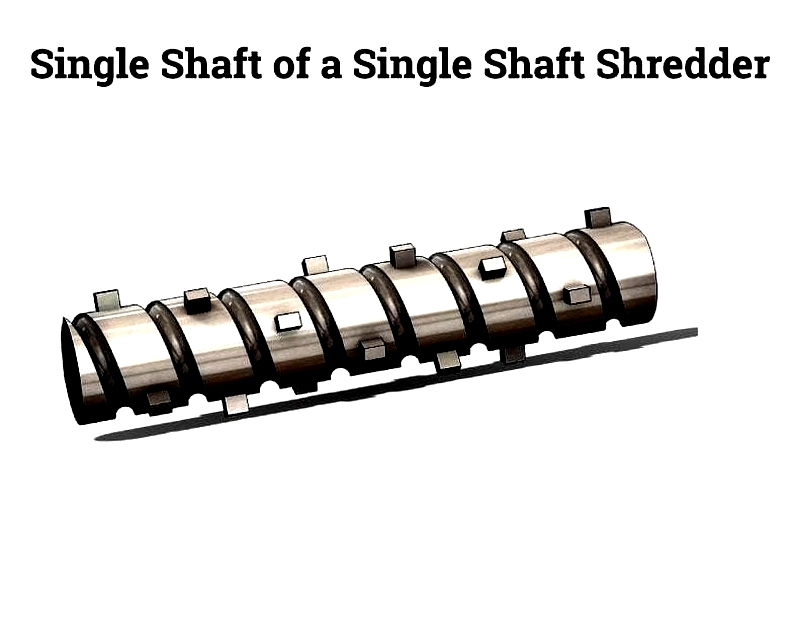

Single Shaft Shredder

Popular in recycling plants, single shaft shredders feature a rotating shaft with cutting blades and a hydraulic feed system. They operate at low RPMs, producing uniform 1-2 inch particles ideal for plastics, wood, and e-waste processing.

Double Shaft Shredder

Designed for large-scale processing, dual shaft shredders use counter-rotating blades to break down bulk materials like municipal waste and construction debris. Their robust construction handles challenging recycling applications.

Three Shaft Shredder

With an additional cutting shaft, these shredders optimize throughput for complex operations like product destruction and bundled material processing. Their design prevents jams and ensures consistent output.

Four Shaft Shredder

The most versatile option, four-shaft shredders perform primary and secondary shredding simultaneously. They're ideal for high-security applications and processing rigid materials requiring precise size control.

Horizontal and Vertical Hammermill Shredder

These heavy-duty machines use powerful hammers to process scrap metal at high speeds. Configurations include gravity discharge and full-circle screen models, handling up to 350 tons per hour in metal recycling operations.

Grinder

Industrial grinders reduce wood, construction debris, and industrial waste into small particles. Available as tub or horizontal models, they're used in mulch production and biomass preparation.

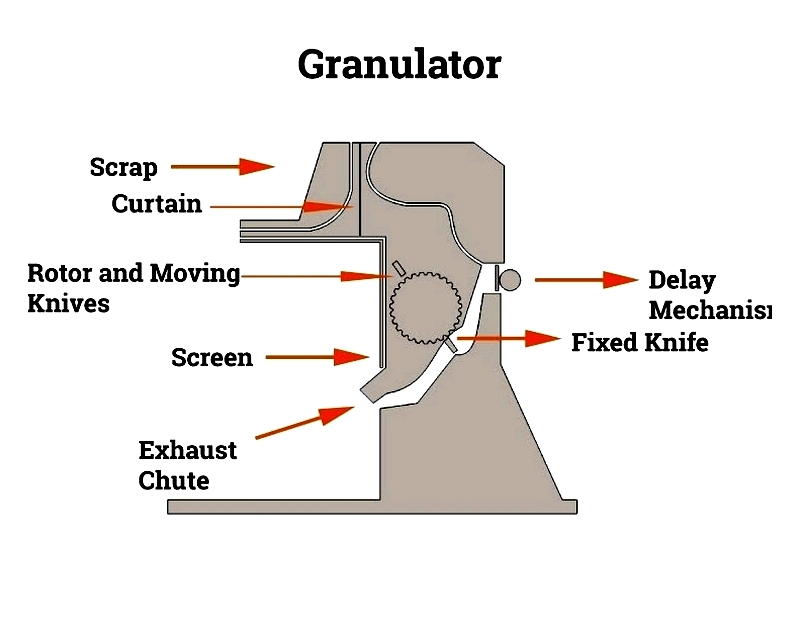

Granulator

Specialized for plastics recycling, granulators produce uniform flakes for manufacturing. Their high-speed rotors make them essential for closed-loop recycling and resin pelletizing.

Industrial Slitters

These precision machines convert material rolls into narrower widths for manufacturing. Available as roll slitters or slitter rewinders, they're crucial in packaging and paper industries.

Industrial Chopper

Designed for rapid sizing of waste materials, choppers feature rotating drums with multiple blades. They're used in recycling centers and manufacturing plants for efficient material processing.