Introduction

This article provides an in-depth examination of vibration absorbers.

It covers essential topics including:

- Operating Principles of Vibration Absorbers

- Damping Mechanisms in Vibration Absorbers

- Varieties of Vibration Absorbers

- Practical Applications of Vibration Absorbers

- Additional Relevant Topics

Chapter 1: Operating Principles of Vibration Absorbers

This section examines vibration absorbers, detailing their terminology and working mechanisms.

Fundamentals of Vibration Absorbers

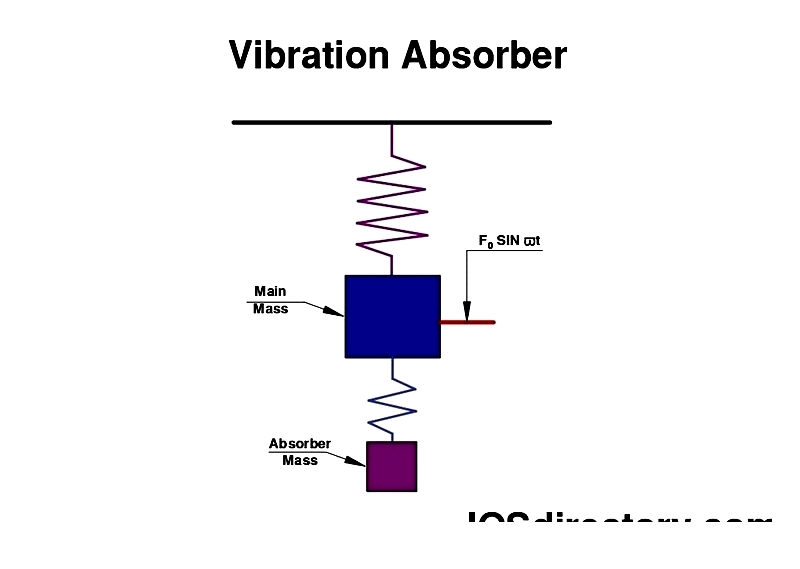

A vibration absorber is a spring-mass system with single-degree freedom (DOF) designed to manage vibrations in systems affected by harmonic forces, including engines, motors, and conveyors. Its primary function is to reduce or eliminate these vibrations, ensuring smoother and safer operation. Typically installed on vibrating systems, these devices generate "anti-resonance" to counteract unwanted oscillations. The illustration below demonstrates how a vibration absorber addresses these oscillations.

Key Terminology

Since vibration absorbers are common in many machines and mechanical systems, understanding their terminology is crucial. The following sections provide detailed explanations.

Vibration in Absorber Context

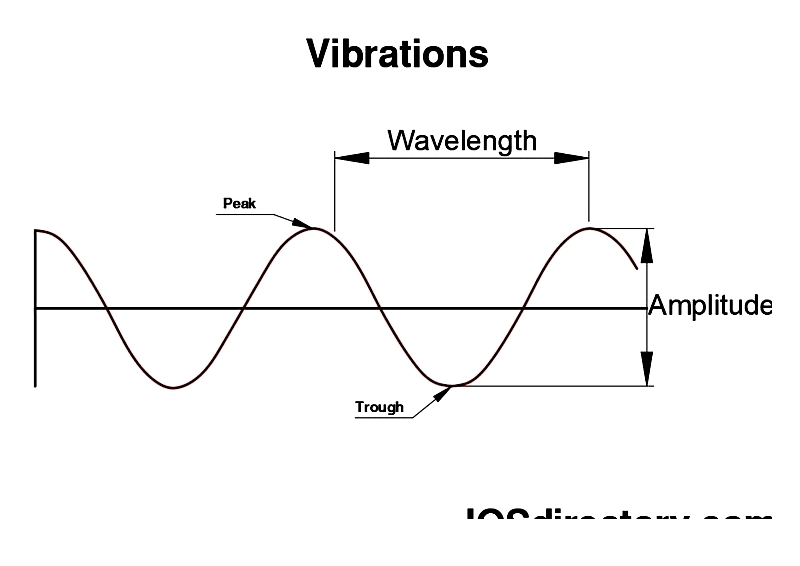

Vibration refers to mechanical oscillations around an equilibrium point. While beneficial in some applications like concrete mixing, vibrations often cause undesirable noise and energy loss. In electric motors, engines, and various mechanical operations, vibrations are typically unwanted. Absorbers are employed to minimize or eliminate these vibrations when necessary.

Resonance Explained

Resonance occurs when an external force's frequency matches a system's natural frequency, amplifying vibration amplitudes. This phenomenon can be either advantageous or detrimental. In construction, resonance often causes structural damage, while in music, it enhances sound production in instruments.

Amplitude Definition

Amplitude measures the maximum displacement of an object or point from its equilibrium position. For sound waves, it determines the volume or loudness of the produced sound.

Energy Absorption

Energy absorption involves reducing the intensity of random motion (vibrations).

Natural Frequency

Natural frequency is the number of vibration cycles a freely vibrating object completes in a given time period.

Shock Definition

Shock describes the displacement of a body from equilibrium due to sudden force application.

Vibration Control

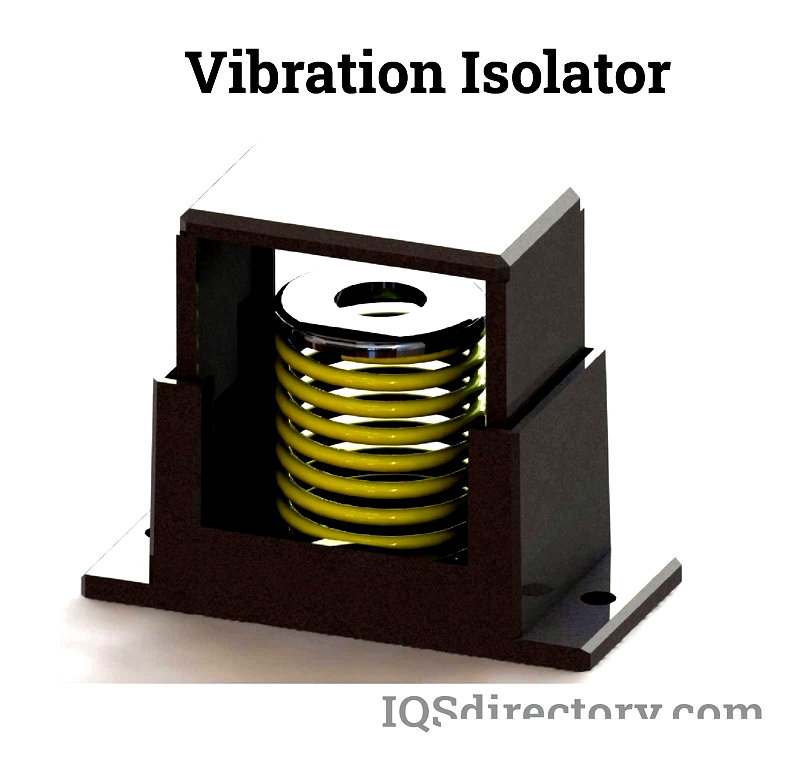

Vibration control uses devices like isolators, dampers, and mounts to capture kinetic energy from vibrating elements, preventing its transfer to adjacent surfaces.

Operation of Vibration Absorbers

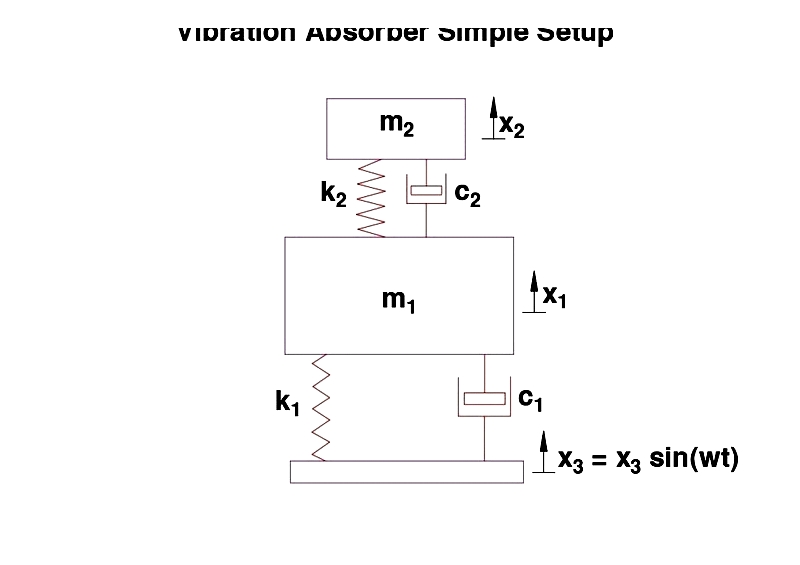

Vibration absorbers are typically used in systems operating at constant speeds or under continuous exciting frequencies. The setup includes both the main system and the absorber, as shown in the diagram below.

Installation Setup

The following describes the arrangement for installing vibration absorbers:

Primary System (Payload)

The primary system, or payload, is the component experiencing unwanted frequencies requiring management. Examples include motors, engines, and bridges. Its natural elasticity allows it to return to its original shape after deformation.

Absorber Function

The absorber, or support, helps the primary system by reducing or eliminating vibrations. This may involve rubber mounts, springs, or hydraulic systems.

Energy Absorption Process

Equipment vibrations represent kinetic energy dissipated through random oscillations. Rubber effectively absorbs this energy due to its elasticity and durability. Common rubber types used include silicone, butyl, fluoroelastomer, neoprene, and EPDM.

Hydraulic Shock Systems

Hydraulic systems consist of a cylinder, piston rod, and fluid. Vibrations move the piston rod, causing fluid motion that converts kinetic energy into heat. The diagram below shows hydraulic shock absorber components.

Design Considerations

Effective vibration absorber design requires careful consideration. Solutions may involve springs with rubber or simple rubber mounts, depending on system complexity.

Rubber Mount Design

Rubber mounts dampen vibrations by being placed between components. They reduce wear and maintenance costs, available in various shapes and materials.

Mount Deformation

Rubber mounts can deform under load. Proper design and finite element analysis ensure effective vibration control. Shock loads significantly impact deformation.

Rubber Isolator Fabrication

Rubber isolators combine springs and rubber for enhanced performance. Manufacturing methods include molding and extrusion, with additives like sulfur or urethane for improved properties.

Chapter 2: Damping in Vibration Absorbers

This section explores damping in vibration control systems, covering types and methods used in industrial applications. Understanding these principles is vital for mechanical efficiency and durability.

Damping Types

Damping minimizes unwanted oscillations, resonance, or vibrations. Key types include overdamping, underdamping, and critical damping, each with unique characteristics for mechanical design.

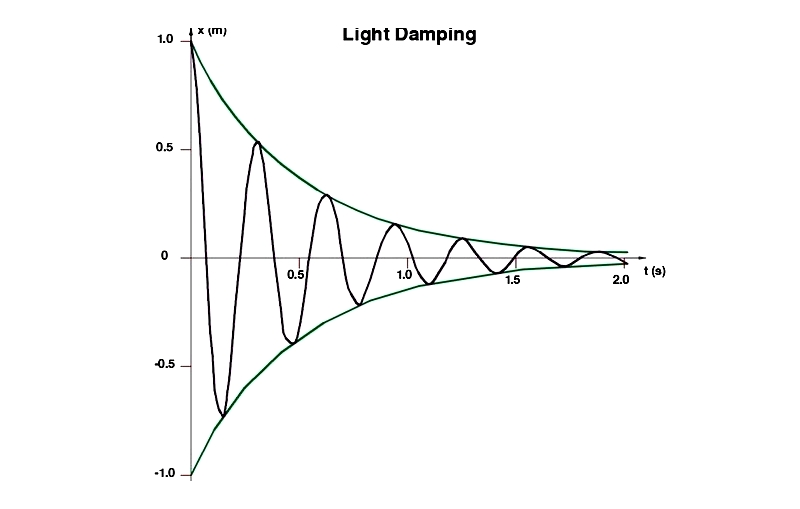

Light Damping

Light damping features gradual oscillation decay. Examples include playground swings or clock pendulums, where motion persists before diminishing due to friction.

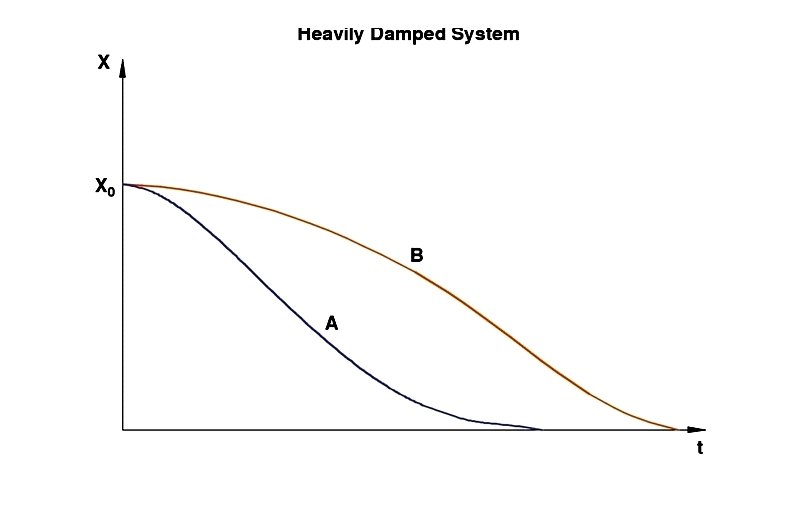

Heavy Damping

Heavy damping (overdamping) causes smooth stabilization without oscillations. Examples include hydraulic door closers preventing slamming.

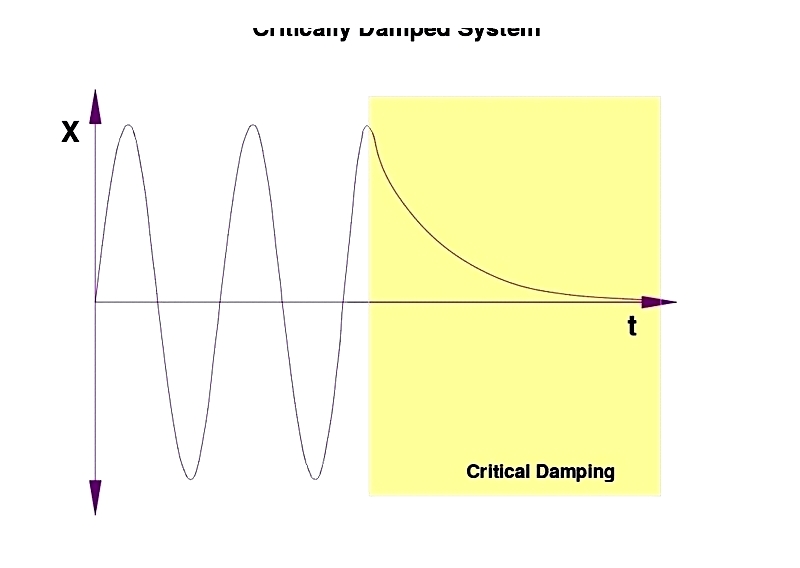

Critical Damping

Critical damping ensures rapid equilibrium return without overshooting. Applications include automotive suspensions for improved stability.

Vibration Damping Methods

Vibration damping absorbs kinetic energy from oscillations, reducing material fatigue and noise. Key techniques include:

Unconstrained Damping

This method uses elastomeric pads between components to absorb energy. Common in HVAC and machinery for vibration reduction.

Constrained Damping

Constrained layer damping (CLD) sandwiches viscoelastic materials between rigid layers for enhanced vibration control in precision applications.

Tuned Viscoelastic Damping

This approach targets specific frequencies using custom materials, ideal for sensitive environments like medical devices.

Vibration Isolation

Vibration isolation separates sensitive components from vibration sources, extending equipment life and reducing noise.