Introduction

This article provides an in-depth exploration of screw machined parts and products.

It covers detailed information on various topics, including:

- Principles of Screw Machined Parts and Products

- Parts and Products

- Types of Screw Machines Used in Screw Machining

- Applications and Benefits of Screw Machined Parts and Products

- And much more...

Chapter 1: Principles of Screw Machined Parts and Products

This chapter explores screw machined parts and products, detailing their definitions and the machining techniques used in their production.

What Are Screw Machined Parts and Products?

Screw machined parts are precision cylindrical and threaded components made with specialized machinery. These parts are typically produced using automatic lathes for small to medium-sized items. Common examples include screws, bolts, pins, fittings, bushings, rivets, fasteners, and studs. These components are essential in manufacturing and widely used in construction and maintenance industries.

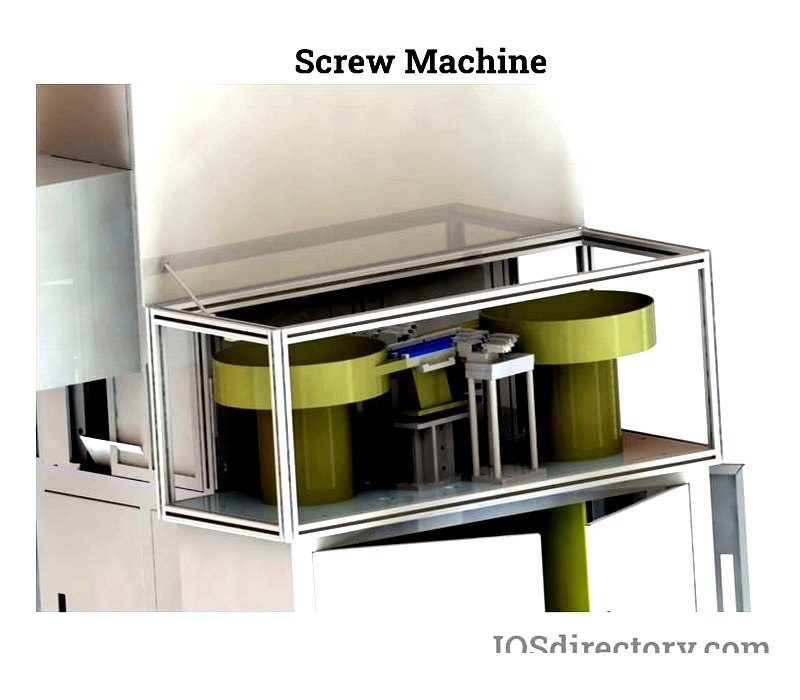

A screw machine is an automated lathe designed for rapid part production. These machines often feature multiple spindles, typically six, enabling simultaneous processing of identical materials for efficient high-volume output. They work with various materials, including aluminum, plastic, wood, brass, and steel, producing diverse screw machine parts.

Screw machine products are crucial in industries such as automotive, agricultural, medical, electronic, and leisure. Multi-spindle screw machines produce items with precise tolerances, enhancing production speed and cost-efficiency while reducing resource consumption.

Screw Machining Processes

Screw machine shops improve efficiency by equipping staff with essential tools for precision machining. based on client needs, they select appropriate designs, materials, and machining options. Screw machines, whether single or multi-spindle, process bars up to 12 feet long in square, round, or hexagonal shapes, resembling Civil War-era Gatling guns in setup.

Automated tools, including those for drilling, cutting, notching, and knurling, shape rotating stock into desired parts. These tools, integrated into the screw machine, drill, trim, and smooth the stock. Manufacturers typically arrange these tools in stations along turret, horizontal, and vertical slides. Different screw machines perform various processes, including:

Knurling Process

Knurling adds a textured pattern to metal surfaces to improve grip. Specialized tools create distinct patterns, commonly used on tool handles, metal flashlights, knurled nuts, and knobs. This process is widely applied in electronics, automotive, construction, aerospace, telecommunications, fitness equipment, and maritime sectors. Performed on lathes with automatic-feed mechanisms, it ensures precision and efficiency.

Knurling tools, paired with a lathe, emboss patterns on materials, creating three-dimensional designs. The four main knurl patterns are diamond, straight, angular, and circular rings, which can be combined for specific effects. Annular rings are often used with plastic parts to enhance grip and functionality.

While annular rings improve part coupling, they can complicate separation due to ridges. Straight knurl patterns feature parallel ridges, while helical knurl patterns are created by turning straight ridges into helical grooves.

Angular knurling, with single-direction angled ridges, improves external handle traction. Diamond knurling is preferred for hand grips, offering maximum traction with cross-hatch ridges.

Thread Rolling and Forming Process

Screw heads are formed using pressure techniques with a die. Thread rolling forms metals cold, requiring ductile workpieces that compress at low temperatures.

Thread formation in screw heads is often done on lathes for efficiency. Thread rolling uses hardened dies to create threads without material removal, enhancing production efficiency.

This method strengthens screws and threaded parts, producing robust components with consistent threads. The process uses flat and cylindrical dies. Flat dies, with simple contours, are common for woodscrews and machined screws, while cylindrical dies come in two-feed and three-feed varieties for different applications.

Thread rolling increases product strength and dimensional accuracy but is limited to softer metals and involves higher tooling costs. Dies must be durable and precise, with deformation affecting thread accuracy.

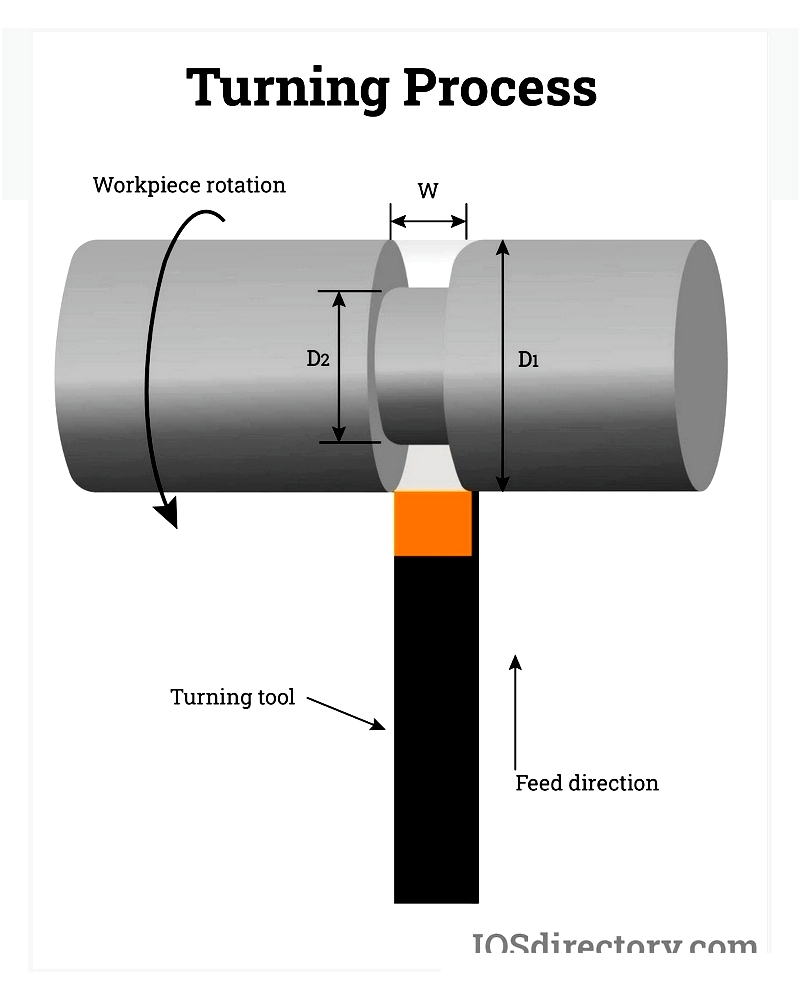

Turning Process

Turning involves a non-rotary cutting tool moving linearly as the workpiece spins, creating a helical toolpath. This process shapes external surfaces ("turning") or internal surfaces ("boring").

Lathing includes both turning and boring. "Facing" cuts workpiece faces using similar tools.

Turning can be manual on traditional lathes or automated with CNC lathes. Modern lathes often use computer numerical control (CNC).

During turning, the workpiece spins while the cutting tool moves along multiple axes, creating tubular parts with varied geometries. This allows operations like drilling, slotting, knurling, threading, and milling.

Hard turning: This process is for materials with a Rockwell C hardness above 45, typically after heat treatment, reducing the need for grinding.

Tapered turning: Creates conical shapes by diminishing the diameter.

Grooving: Uses a single-point tool to cut equally-wide grooves into the workpiece, with wider grooves made through multiple passes.

Parting: A cut-off tool advances radially into the workpiece, eventually severing a section.

Surfacing metal Parts

Screw machining shapes metal items and refines surface finishes, achieving knurled or polished results through turning. Secondary operations, often replacing manual tasks, may use a twin spindle CNC Swiss screw machine.

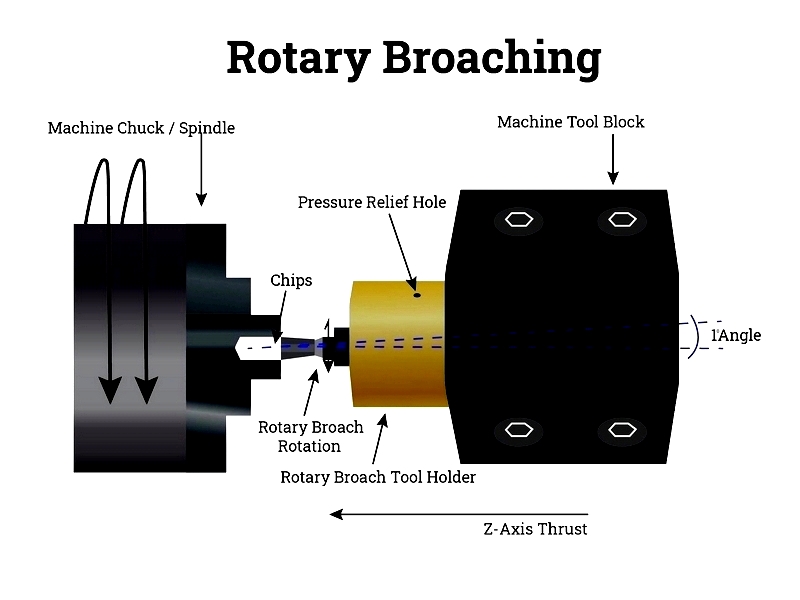

Rotary (Wobble) Broaching Process

Rotary broaching achieves desired internal shapes in a single pass, unlike traditional methods. Effective on machines with horizontal or vertical spindles, it often eliminates further operations.

Rotary broaching quickly forms internal polygonal shapes with high precision. It is widely used in plumbing, automotive, aerospace, and medical industries.

The method relies on the broach's 1-inch angle to the workpiece’s midline. The broach tool's live spindle rotates freely, driven by the lathe's workpiece, cutting with a scalloping effect.

Chapter 2: Parts and Products

This chapter offers a detailed overview of screw machined parts and products, examining their precision manufacturing processes and industrial applications. Understanding these capabilities helps in specifying, sourcing, or purchasing custom machined components.

Screw Machined Products

Manufacturers use advanced CNC screw machines and Swiss machining to create high-precision components for industries like home appliances, industrial construction, automotive, aerospace, medical devices, electronics, military, telecommunications, and healthcare.

Screw machining produces precision-turned parts, custom fasteners, and CNC-turned components. These include button machine screws, hex machine screws, pan head screws, truss machine screws, cap screws, set screws, shoulder screws, dowel pins, bushings, and custom spacers. High-tolerance components for military, aerospace, and defense rely on screw machined parts.

Modern screw machining uses traditional CNC lathes and Swiss CNC lathes. Swiss lathes move along the Z-axis, enabling ultra-precise,