Introduction

This article provides an in-depth exploration of shredding machines.

Key topics covered include:

- Working Principles of Shredding Machines

- Varieties of Shredding Machines

- Applications, Benefits and Industry Standards

- Additional relevant information

Chapter 1: Principles of Shredding Machines

This chapter examines the fundamental concepts of shredding machines, including their structure, design, and operational mechanisms.

What is a Shredding Machine?

A shredding machine is equipment designed to cut materials into smaller pieces. While commonly associated with document destruction for privacy protection, these machines come in various types tailored for specific materials and applications.

Shredding machines handle diverse materials for recycling purposes, including plastics, metals, e-waste, wood, and tires. The process yields raw materials for manufacturing or finished products like mulch. Related equipment includes grinders, granulators, and hammer mills, all focused on size reduction.

Machine Components

Shredding machines consist of several key elements:

Main Components

Industrial models typically feature feed shafts, a loading zone, cutting blades, a motor, and an output chute that directs shredded material to conveyors or collection bins.

Screens often capture oversized pieces for reprocessing until proper sizing is achieved.

Design Considerations

Machine design factors include material type, volume, operating environment, available space, usage frequency, and budget constraints.

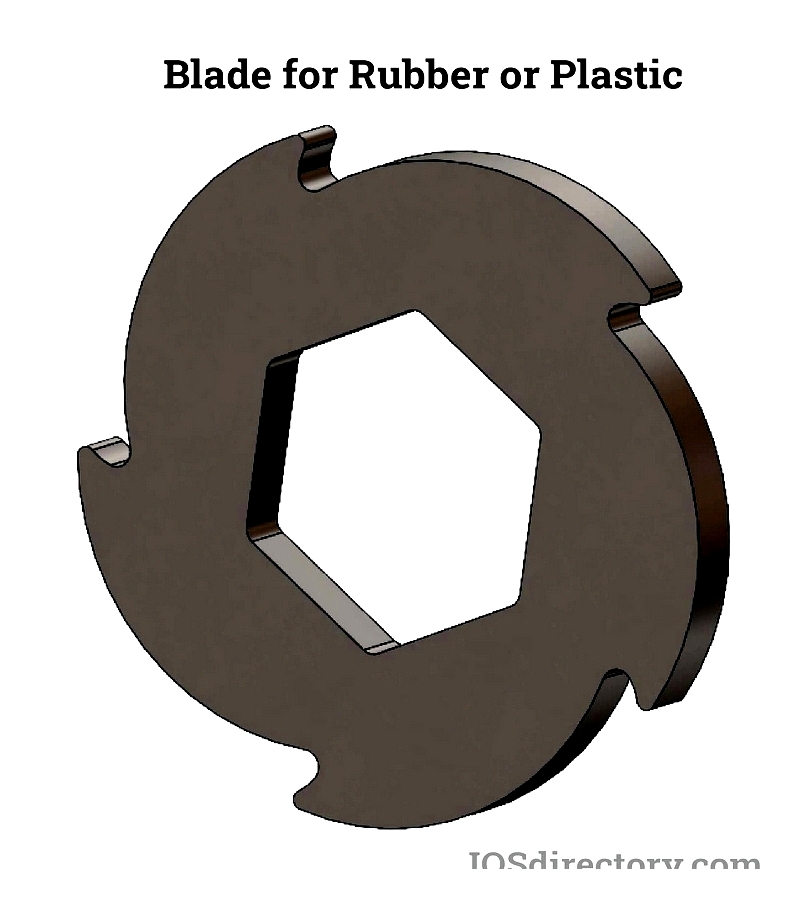

Cutting Blade Design

Blade hook size and configuration depend on material type. Larger hooks increase production but must match machine capacity to avoid jams. Common blade materials include tool steel and carburizing steel, with specialty alloys for specific applications.

Shaft Specifications

Shaft design focuses on diameter requirements for strength and durability under operational loads. Ideal shaft materials offer:

- High strength

- Good machinability

- Excellent heat treatment properties

- Wear resistance

Carbon steel is standard, with alloy steels used for higher strength needs.

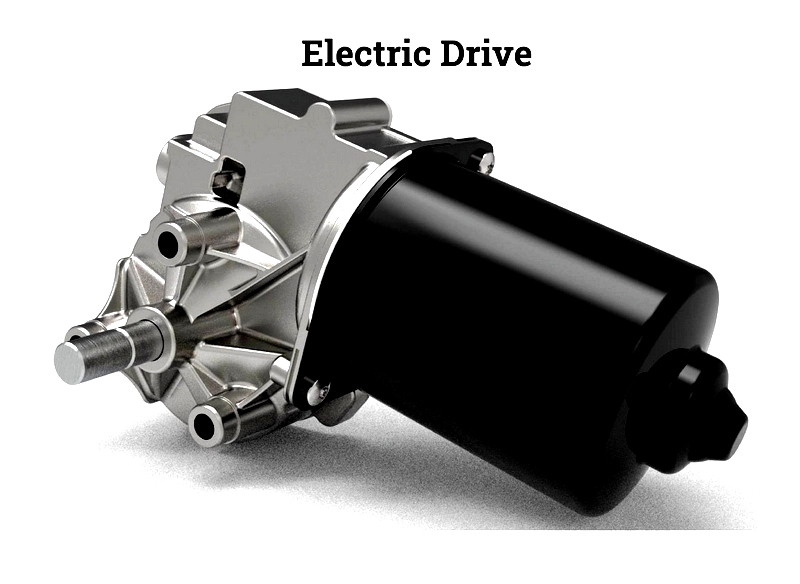

Drive System Options

Electric Drives: These power blade rotation, with motor size varying by machine type. Electric systems are compact, user-friendly, energy-efficient, and cost-effective for most materials.

Hydraulic Drives: Preferred for heavy-duty applications like tire shredding, these systems handle batch feeding and shock loads effectively. They're ideal for:

- Batch processing

- Mixed material feeds

- Difficult-to-shred materials

- Precise particle size control

- Process coordination needs

- Frequent start-stop operations

- Low-voltage start requirements

Machine sizes range from small office units to large industrial systems processing thousands of kilograms hourly.

Shredding Techniques

Three primary methods are employed:

Shearing

This scissor-like cutting action depends on blade sharpness and spacing. Advanced alloys maintain cutting precision over time.

Tearing

Force separates materials like fabrics, soft metals, and plastics. Effective for mixed waste where uniform sizing isn't critical.

Fracturing

Brittle materials like hard plastics and glass break apart. Safety precautions are essential due to potential fragment projection.

Optimal Performance

Shearing typically offers greatest efficiency when blades are sharp and properly adjusted.

Material Types

Ductile Materials: Resist fracturing, forming long strips when torn. Includes paper, cloth, rubber, and soft metals.

Friable Materials: Easily fracture into small pieces. Examples include glass, stone, and hard plastics.

Selection Criteria

Key factors when choosing a shredder:

Material Compatibility

Different machines suit specific materials. For example, chippers handle branches, while twin-shaft models reduce dust and noise for mixed waste.

Output Requirements

Consider final particle size needs. Some applications require multiple processing stages.

Capacity

Select a machine with slightly higher capacity than needed to prevent overloading and extend service life.

Feeding Methods

Manual feed hoppers suit smaller operations, while automatic systems improve efficiency for continuous processing.

Operational Factors

Consider safety, mobility, noise levels, and dust control when selecting and positioning equipment.

Maintenance Needs

Regular maintenance is crucial. Consider ease of access for blade replacement and general upkeep when choosing equipment.

Chapter 2: Types of Shredding Machines

Various shredding machines serve specific industrial, recycling, and security needs. Proper selection ensures efficiency, compliance, and cost-effectiveness across applications from packaging to metal recycling.

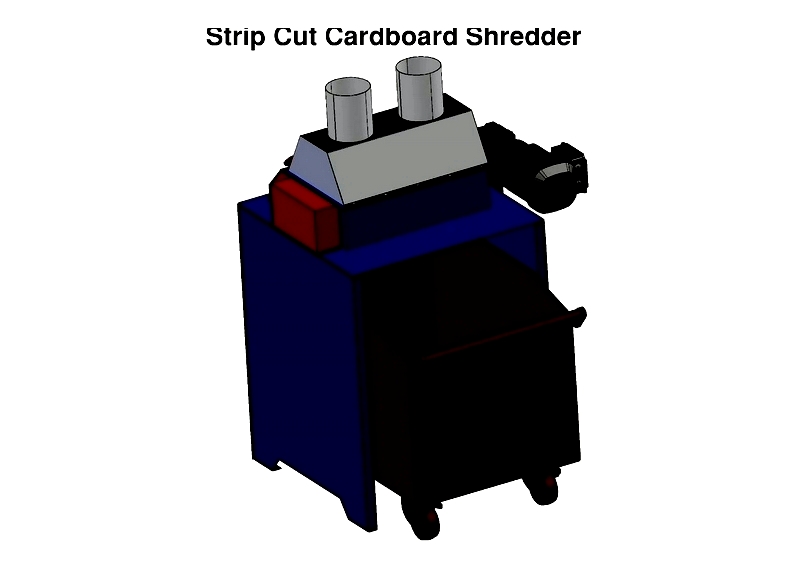

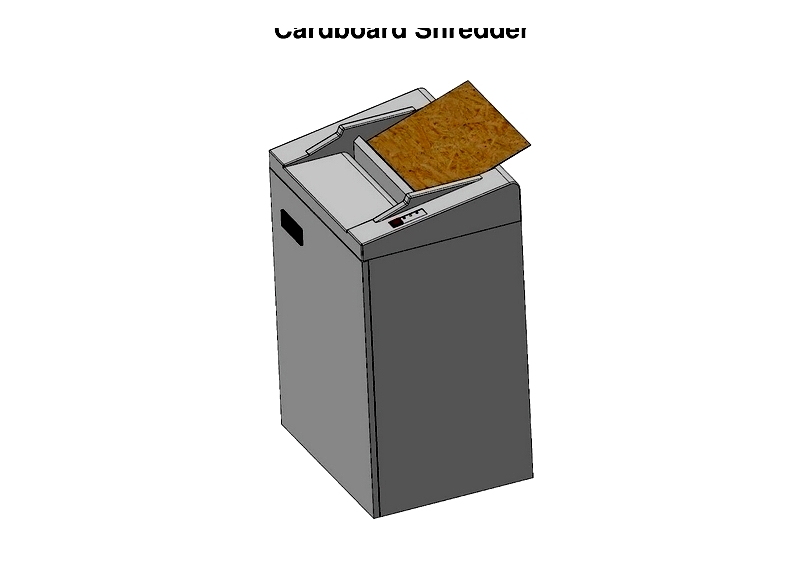

Cardboard Shredder

These industrial machines transform cardboard waste into packaging materials like cushioning netting or strips, supporting sustainability goals. They operate similarly to heavy-duty paper shredders, creating eco-friendly void fill from discarded boxes.

Cardboard shredders reduce waste disposal costs while eliminating the need for new packing materials. Businesses use the output to protect goods during shipping while meeting recycling targets and reducing environmental impact.

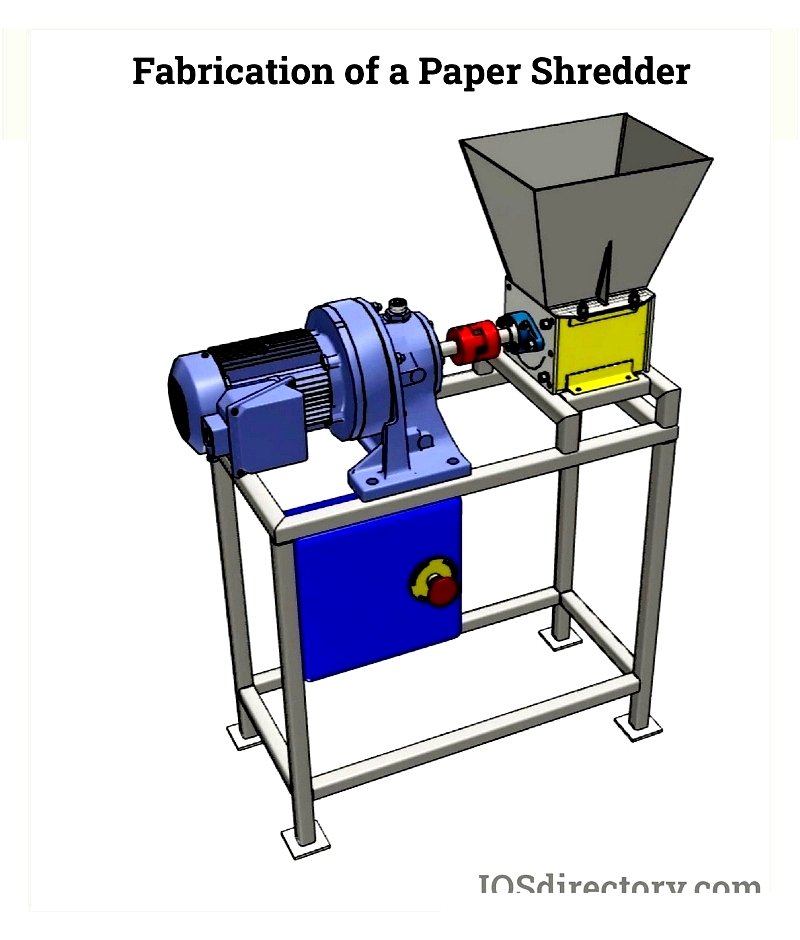

Paper Shredder

These electronic devices destroy sensitive documents for data protection and compliance. Cutting blades powered by electric motors produce particles meeting various security standards.

Paper shredders fall into three main categories:

Strip Cut

Creates long strips from non-confidential documents. Features include:

- Basic security level

- Suitable for general office waste

- Vertical cuts only

- DIN P-1/P-2 security rating

Cross Cut

Produces confetti-like pieces for confidential documents. Characteristics:

- Medium security

- Diagonal cutting pattern

- DIN P-3/P-4 rating

Micro Cut

Gener