Introduction

This article provides comprehensive details about wire rope assemblies and their applications.

You will discover:

- The definition of wire rope assemblies

- Different types of wire rope assemblies

- Key components of wire rope assemblies

- Materials used in wire rope construction

- Advantages of using wire rope assemblies

- And additional valuable information

Chapter One: What Is a Wire Rope Assembly?

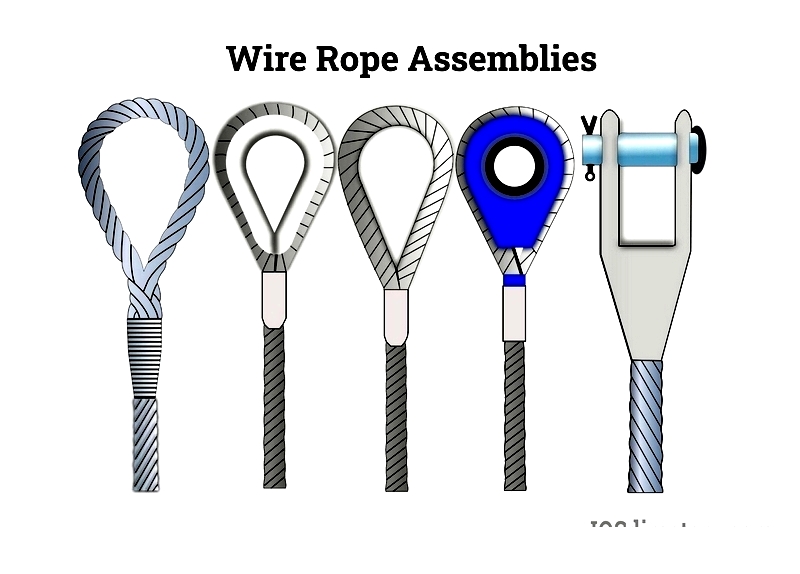

A wire rope assembly consists of a wire rope integrated with end fittings, terminals, or lanyards attached to various sections. This configuration is specifically designed for lifting, hoisting, and transporting loads. Available in multiple configurations, each assembly is tailored for specific lifting needs - from small rigging systems for precise component positioning to large-scale applications like suspension bridge support.

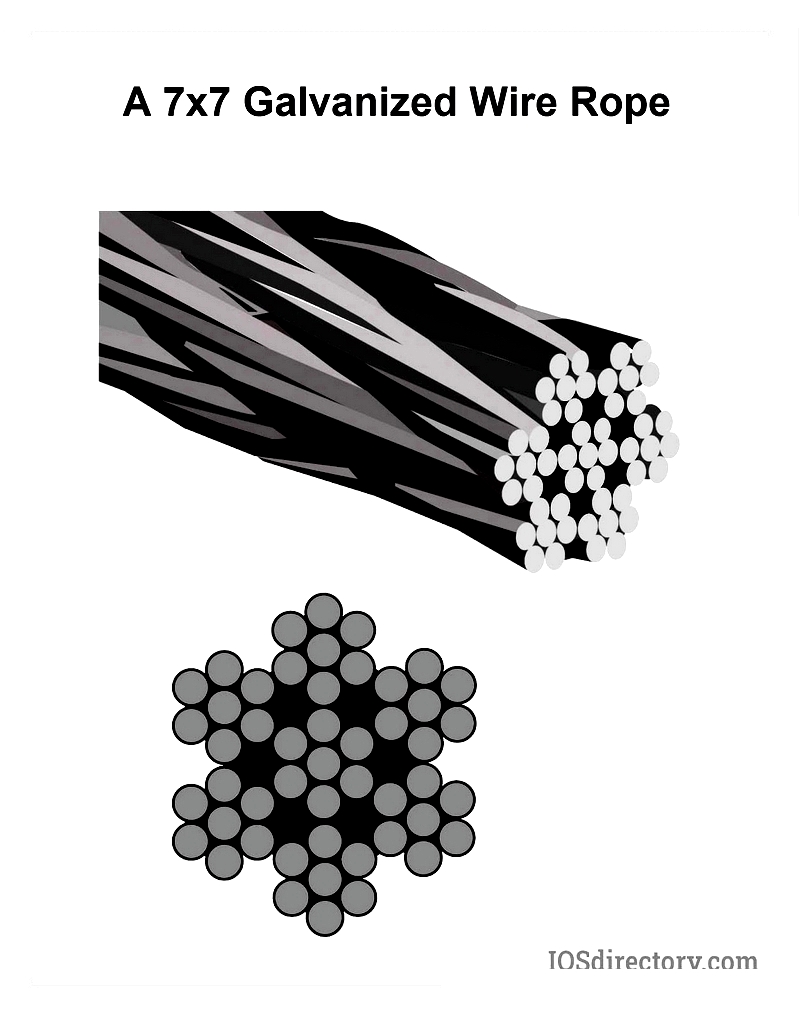

The core element of these assemblies is the wire rope itself, which varies in construction and strand arrangement. While individual wires may not support significant loads, when carefully arranged and twisted into strands, they create a powerful tool capable of lifting substantial weights efficiently.

Chapter Two: What are the Different Types of Wire Rope Assemblies?

Wire rope assemblies, also known as cable assemblies, come in numerous designs for specific applications across industries like construction, marine, mining, and manufacturing. Selecting the appropriate assembly is crucial for safety, efficiency, and compliance with industry standards. These assemblies are built to withstand heat, corrosion, and abrasion, delivering reliable performance under demanding conditions. Using an improperly rated wire rope can lead to equipment failure, damage, or injury, emphasizing the importance of understanding each assembly type's unique properties.

Wire ropes are available in various grades and materials, including galvanized steel, stainless steel, and high-carbon steel, each offering distinct advantages in tensile strength, flexibility, and environmental resistance. Manufacturers typically provide detailed specifications covering construction, strand count, breaking strength, flexibility, working load limits, and recommended usage environments. Professional consultation can help determine the most suitable assembly for specific lifting, rigging, or securing needs.

Push Pull Wire Rope Assemblies

Push-pull assemblies, or mechanical control cables, are flexible systems designed for transmitting precise linear motion over distance. Commonly used in throttle controls, brake systems, and valve operations, these cables provide smooth, low-friction movement even around complex bends. Their internal polymer jacketing protects against abrasion and contaminants, ensuring long-term performance in industrial, automotive, and marine applications.

Single Leg Wire Rope Slings

Single-leg slings are fundamental lifting components known for their simplicity and durability. Comprising a single steel wire rope with swaged eyes or hooks, they're ideal for lifting machinery and construction materials. Available in galvanized or stainless steel, these slings are rated by diameter, breaking load, and lifting angle - requiring careful reference to manufacturer specifications before use.

Multi-Leg Wire Rope Slings

Multi-leg slings feature two or more wire rope legs joined at a master link, enabling even load distribution and greater stability for irregular or oversized loads. Configurations include two-leg, three-leg, and four-leg designs with various end fittings, making them essential for heavy construction, shipbuilding, and material handling operations.

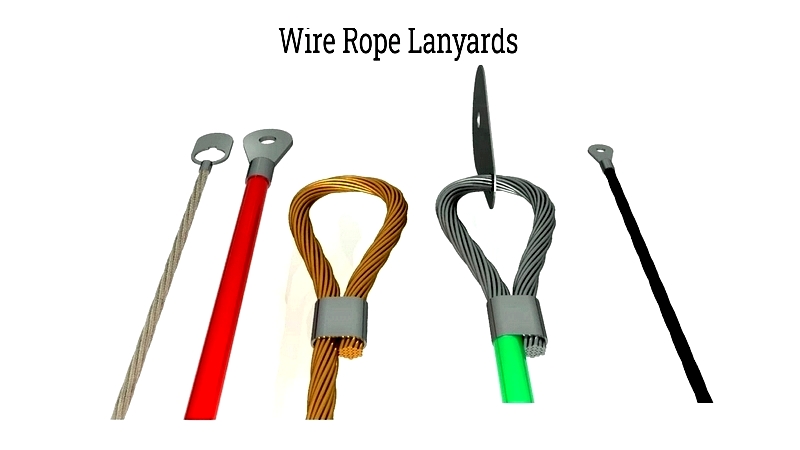

Wire Rope Lanyards

Safety lanyards prevent tools or equipment from falling in hazardous environments like scaffolding or towers. Made from durable galvanized or stainless steel, these lanyards withstand dynamic loads while resisting abrasion and corrosion. Customizable with various terminations and lengths, they must meet OSHA and ANSI safety standards.

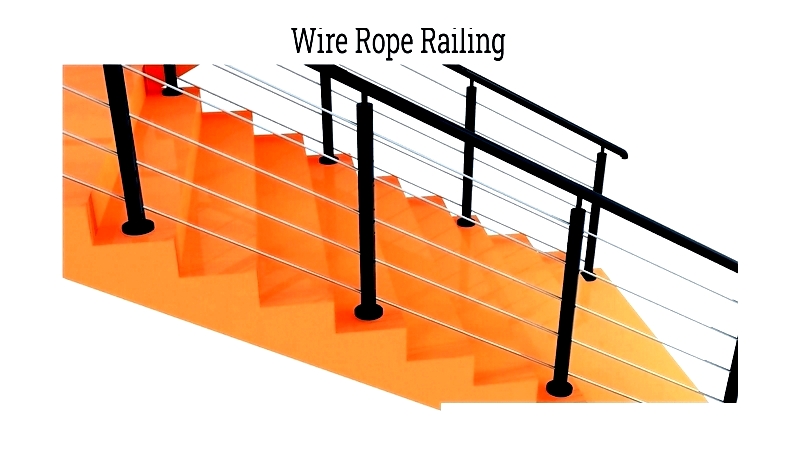

Cable Railings

Architectural wire rope assemblies used for modern guardrails and balconies provide fall protection with minimal visual obstruction. Tensioned stainless steel cables offer corrosion resistance, especially in coastal environments, and can be installed with various fittings for enhanced safety and aesthetics. Proper tensioning and spacing are essential for code compliance and structural integrity.

Guy Wire Assemblies

Essential for supporting structures like transmission towers and antennas, guy wires consist of high-tensile steel rope with turnbuckles and clamps for tension adjustment. Properly installed, they resist wind and storm loads, requiring compliance with ASTM and ISO standards for safety.

Wire Rope Tethers

Specialized restraint cables secure cargo and equipment in marine, offshore, and aerospace applications. With high breaking strength and corrosion resistance, these tethers feature customizable lengths and attachments for safety-critical operations.

Control Cables

Precision-engineered for transferring mechanical motion, control cables are vital in automation, robotics, and industrial equipment. Designed for high-cycle use, they offer abrasion resistance and environmental sealing for harsh conditions.

Winch Lines

Robust assemblies for extreme pulling in industrial, marine, and off-road applications. High-strength steel construction with heavy-duty hooks or eyelets makes them ideal for towing and recovery operations. Regular inspection is recommended to maximize service life.

Cane Cables

Specialized agricultural cables for sugar cane harvesting, designed to withstand dirt, water, and mechanical stress. Typically made from galvanized or stainless steel for durability in field conditions.

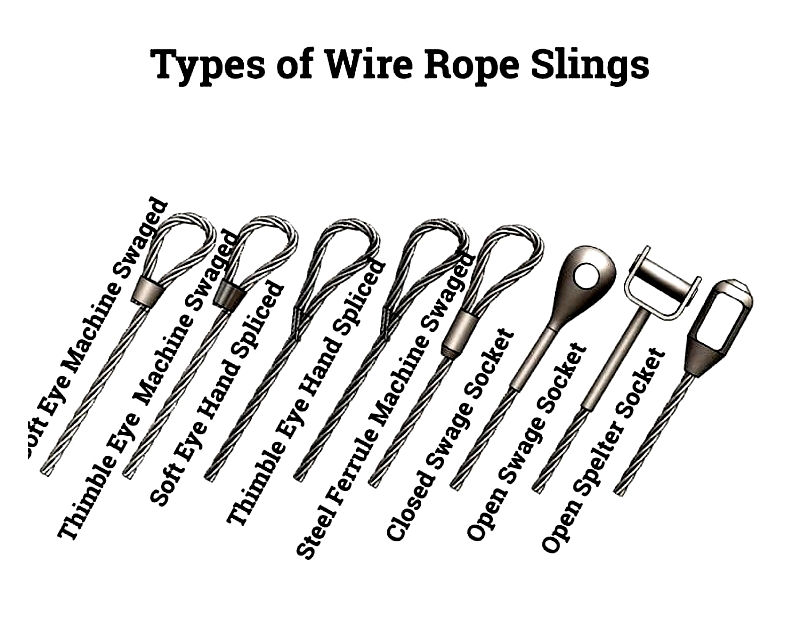

Wire Rope Sling Assemblies

Versatile lifting devices ranging from simple single-leg to complex multi-leg configurations. Selection depends on rope diameter, construction, and end fittings, with adherence to ASME and OSHA guidelines for safety and performance.

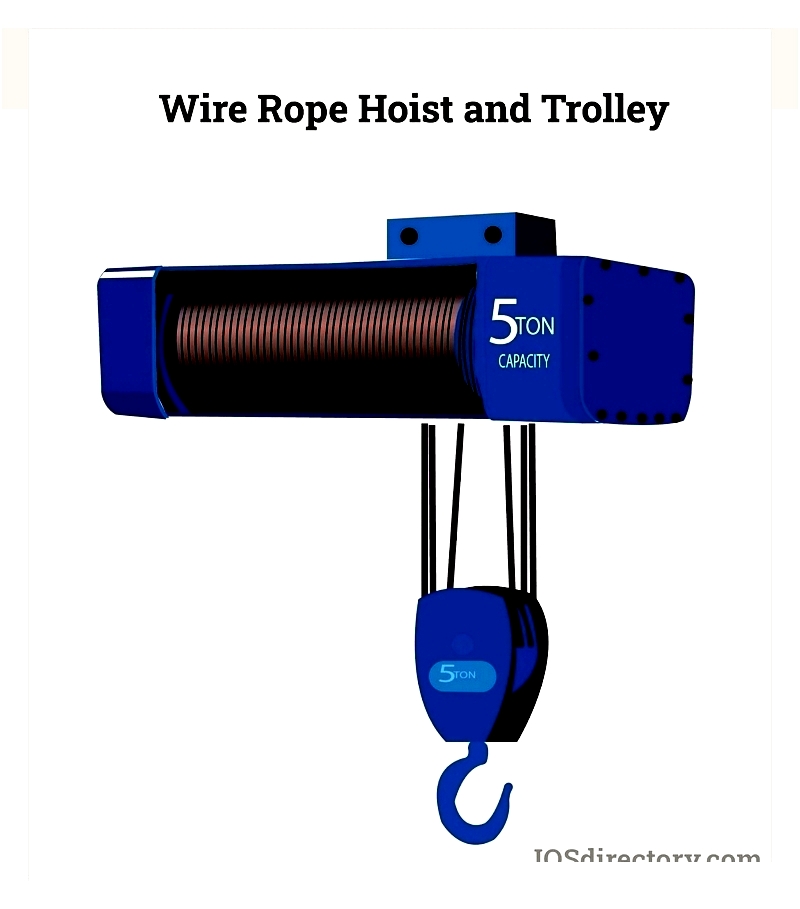

Wire Rope Hoists

Electric or manual lifting devices using steel cable for overhead crane systems. Available in various capacities, they offer durability and precision for material handling operations. Selection factors include load weight, lift height, and environmental conditions.

Wire Rope Catenary Systems

Curved support structures for bridges, conveyors, and lighting. Engineered for proper tension and load distribution using high-tensile steel, these systems require regular inspection for fatigue and corrosion.

Selecting the appropriate wire rope assembly requires understanding load requirements, environmental factors, and application specifics. By evaluating different types and their benefits, users can make informed decisions that enhance safety, efficiency, and value across various industries.

Chapter Three: What are the components of a wire rope assembly?

A wire rope assembly combines wire rope with precision-engineered end fittings for diverse industrial applications. Component selection is critical as each configuration meets specific load, safety, and corrosion resistance needs. End fittings securely attach to rope ends, enabling reliable connections with equipment or structures.

Hooks

Essential connection points for lifting and rigging, available in various shapes and load ratings. Made from high-strength alloy or stainless steel, hooks are versatile for material handling and crane operations.

Eyelets

Form secure loops for attaching hardware like shackles or bolts. Constructed from aluminum, stainless steel, or carbon