Introduction

This article provides an in-depth examination of wire rope.

You will explore various topics including:

- What is Wire Rope?

- Applications of Wire Rope

- Different Types of Wire Rope Products

- Wire Rope Manufacturing Process

- And more...

Chapter One – What is Wire Rope?

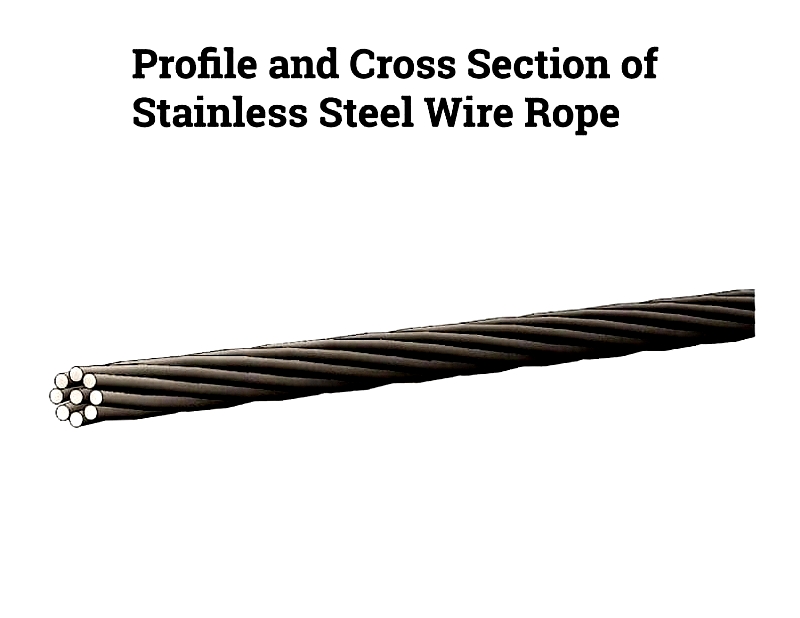

Wire rope is composed of multiple wire strands twisted together in a spiral or helical pattern. When these individual wires are combined into a unified structure, they form a single, stronger cable. This configuration enables the strands to distribute pressure uniformly, offering greater flexibility than single wires.

To further enhance their strength, wire ropes are assembled and twisted to create cables. This process significantly increases their functionality, making them more effective for supporting, lifting, and maintaining structural stability.

A key feature of wire rope construction is the strand lay, which can be classified as either regular or lang. Regular lay, also known as right or ordinary lay, involves strands wound from left to right, with wires laid in the opposite direction of the strand's orientation. In contrast, lang lay features wires wound in the same direction as the strand's layout.

The design and composition of wire rope result in a product with exceptional strength, remarkable flexibility, and outstanding resistance to continuous bending stress. Additionally, wire rope's weather-resistant properties ensure durability in diverse environments.

Chapter Two – What Are the Uses for Wire Rope?

Wire rope is a highly versatile engineered product, essential across numerous industries due to its adaptability, tensile strength, and flexibility. Also known as steel cable, wire rope is made from multiple steel wire strands twisted into a helix, forming a durable and robust component. Its engineering makes it ideal for heavy lifting, load-bearing, motion control, and safety-critical applications. From mining and marine to construction and aerospace, the diverse applications of high-performance wire rope ensure it remains indispensable for operations requiring strength, endurance, abrasion resistance, and secure load handling.

Wire Rope Applications

Aeronautics

In aerospace, wire ropes—often called Bowden cables or aircraft control cables—connect cockpit pedals, levers, and flight control surfaces, transmitting mechanical power to critical systems. These aviation-grade cables are essential for adjusting propeller pitch, cowl flaps, and throttle controls in aircraft. For optimal safety, aircraft wire rope systems are insulated to reduce vibrations and minimize wear. The high fatigue resistance and flexibility of galvanized or stainless steel aircraft cable ensure reliable performance under demanding conditions.

Automotive

Wire rope and steel cables play a vital role in the automotive industry due to their versatility and high load capacity. Common applications include power window regulators, sunroof mechanisms, parking brake cables, and steering systems. Automakers also use wire rope for seatbelt retractors, suspension springs, exhaust components, and door mechanisms. During assembly and maintenance, heavy-duty wire ropes are employed in hoists, automotive lifts, and cranes for safe vehicle movement and precise positioning of parts. Their flexibility and consistent performance under repeated bending make them ideal for automotive systems requiring reliable lifting and mechanical movement.

Construction

The construction industry relies heavily on industrial-grade wire rope for lifting, rigging, hoisting, and securing heavy materials. Construction wire rope is designed for high tensile strength and resistance to abrasion and fatigue, ensuring safety and efficiency. Typical uses include crane cables, winch lines, concrete column support, cable-stayed suspension bridges, elevator systems, and reinforcing temporary structures. Labor-intensive projects like tower erection, steel framework placement, and pre-stressed concrete supports benefit from the unmatched durability and load-bearing capacity of galvanized or stainless steel wire rope. Compliance with strict safety standards and regular inspections is crucial in construction environments.

Food Processing

In food processing, stainless steel wire rope is preferred for its sanitary properties, corrosion resistance, and durability during frequent washdowns and chemical cleaning. It is used in conveyor belts, hoisting meat or packaged products, overhead load handling, loading docks, and suspending food-grade enclosures. Food-grade wire rope complies with strict hygiene standards while maintaining strength and flexibility for efficient heavy load movement in manufacturing or storage facilities.

Oil and Gas Industry

The oil and gas sector depends on high-strength, corrosion-resistant wire ropes for offshore and onshore drilling operations. These ropes, often used as drilling lines, mooring lines, and riser tensioning cables, handle extreme loads while enduring harsh conditions like saltwater exposure, chemical contamination, and high pressure. During ocean drilling, engineered wire rope is used for lowering subsea equipment, anchoring rigs, and securing drilling platforms. Advanced construction and coatings enhance resistance to corrosion, fatigue, and strand failure, ensuring greater safety and reducing downtime. Notably, oil rig wire ropes can extend over 10,000 feet and must meet stringent performance standards for safety and longevity.

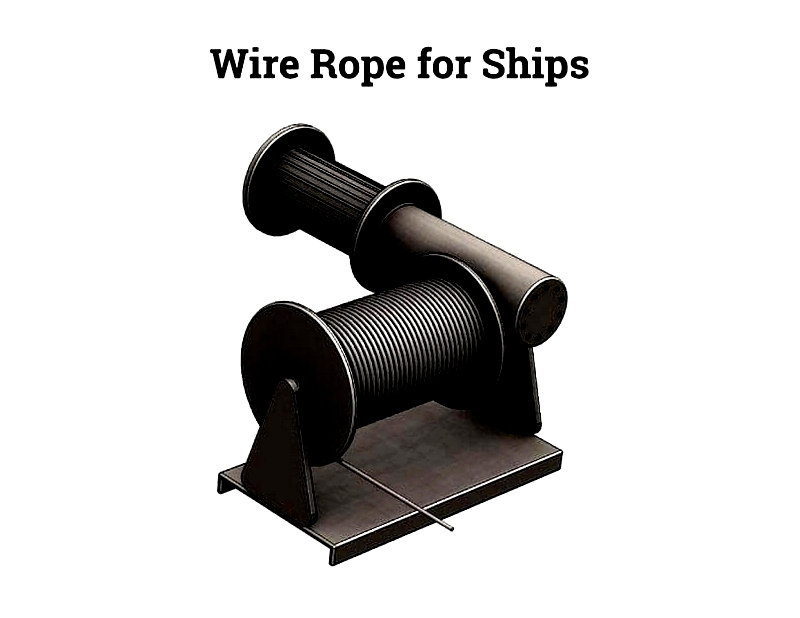

Marine Industry

In marine and shipping, wire rope is critical for mooring, towing, anchor lines, and lifting applications on ships, fishing vessels, and offshore platforms. Marine-grade, galvanized, or stainless steel wire rope offers exceptional resistance to saltwater corrosion. These ropes are used for securing and launching lifeboats, winching heavy cargo, rigging sails on sailboats, and stabilizing masts and booms. Their superior strength-to-diameter ratio and anti-corrosive properties make them ideal for marine engineering and shipbuilding, ensuring safety and reliability in harsh ocean environments.

Skiing

The ski industry uses high-tensile wire ropes for cable car systems, gondolas, chair lifts, and tramways. These lift cables are engineered to support heavy passenger loads and withstand dynamic tensions from constant start-stop operation and extreme mountain climates, including severe cold, snow, and ice. The reliability, safety, and robust construction of ski lift wire rope directly contribute to passenger security and operational uptime. Routine inspection and proper lubrication are essential for extending lifespan and preventing failure.

Amusement Parks

Wire rope has been integral to amusement park ride construction since their inception, providing strength and flexibility for safe operation. From hoisting roller coaster cars and Ferris wheels to supporting ride swing systems and pulling vehicles on tracks, wire rope ensures load management and passenger safety. Amusement ride manufacturers select wire rope based on tensile requirements, fatigue resistance, and compliance with strict safety guidelines. Regular maintenance is crucial in these high-cycling environments to ensure lasting performance and minimize risk.

Stunt Work

Wire rope is essential for safety in the entertainment industry, particularly for high-risk stunts and performer protection. Specialized, lightweight wire ropes are chosen for their strength, flexibility, and near-invisibility on camera. These cables enable secure harnessing, controlled lifts, and stunt rigging for complex action sequences, ensuring both safety and creative freedom. Wire rope specifications for stunts prioritize ease of movement, minimal stretch, redundancy, and high endurance for fail-safe performance during demanding shots.

Architecture and Design

In modern architecture and interior design, wire rope is widely used for decorative and structural purposes, including safety guardrails, cable balustrades, stair railing systems, tensile roof structures, green walls, and plant trellises. Cable railings are popular for their unobtrusive yet secure profile, blending