Introduction

This article provides a comprehensive guide to pneumatic solenoid valves. Continue reading to explore:

- What Pneumatic Solenoid Valves Are

- Working Principle of Solenoid Valves

- Solenoid Valve Components

- Various Types of Pneumatic Solenoid Valves

- And more...

Chapter 1: What are Pneumatic Solenoid Valves?

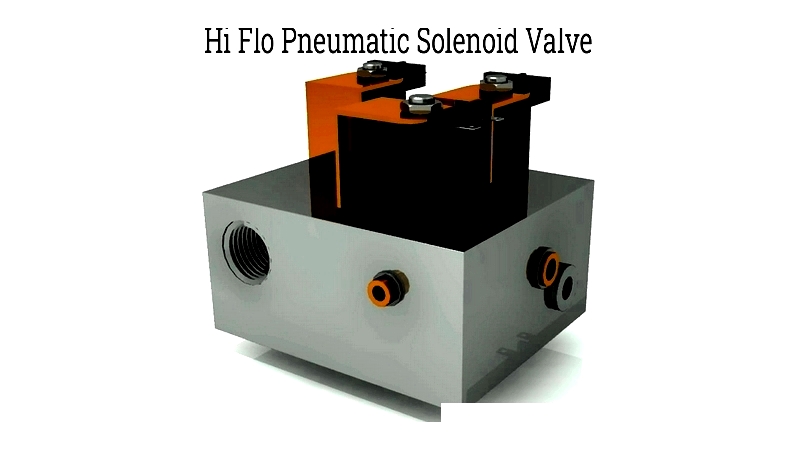

Pneumatic solenoid valves are electromechanical devices that control the flow of air or process gases, playing a crucial role in operating pneumatic actuators like cylinders, turbines, diaphragms, and tubes. Together with actuators, they create auxiliary air circuits to regulate industrial equipment. These valves function by using a plunger within the solenoid core to either permit or block fluid flow.

When activated, a pneumatic solenoid valve generates a magnetic field through an external wire coil, moving the plunger to control system flow. Common types include direct-acting, pilot-operated, and two-way valves. For specialized requirements, engineers can design custom solutions.

Designed to enhance efficiency in machinery and control systems, pneumatic solenoid valves are vital in modern automated industries. They enable processes to operate with minimal manual intervention, making them central to automated environments.

Engineers value pneumatic solenoid valves for their system control capabilities. Their easy installation and electronic operation allow placement in remote locations, making them ideal for complex off-site systems.

These valves demonstrate remarkable versatility across industrial applications. They effectively manage compressed air systems, vacuum systems, ventilation, and air-operated machinery, ensuring safe and efficient operations.

A key advantage is their remote operation capability through low-frequency electrical signals. Control systems can adjust valves in distant process zones, making them essential in oil and gas, power generation, chemical, and plastic industries.

In regulated sectors like medicine and food production, compliance with FDA standards is critical. Pneumatic solenoids ensure precise control over mixing and flow processes, improving quality and production efficiency.

Unlike hydraulic valves, pneumatic solenoid valves operate without fluids, reducing contamination risks. This makes them preferable for medical, pharmaceutical, and food applications where product purity is essential.

Using air power with minimal electrical input, these valves are perfect for robotic arms, automated assemblies, and conveyors. Their efficiency makes them superior to smaller DC motors and hydraulic actuators. Applications include assembly, packaging, material handling, and safety systems.

Chapter 2: Working Principle

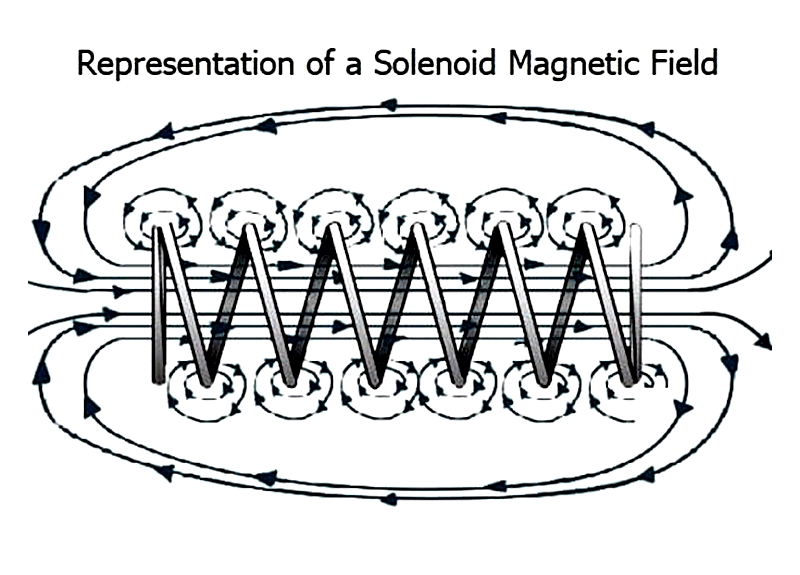

The solenoid is the core component of pneumatic solenoid valves, converting electrical energy into mechanical movement for pneumatic circuits. This electromagnetic actuator consists of a wire coil around an iron core and a ferromagnetic plunger. When current flows, it creates a magnetic field that moves the plunger to control air flow.

Two methods enhance electromagnetic force:

- Increasing coil windings to boost magnetic flux

- Raising current to improve actuation speed and force

These valves work with both DC and AC voltages, suitable for various industrial applications. The choice affects response time, durability, and energy efficiency.

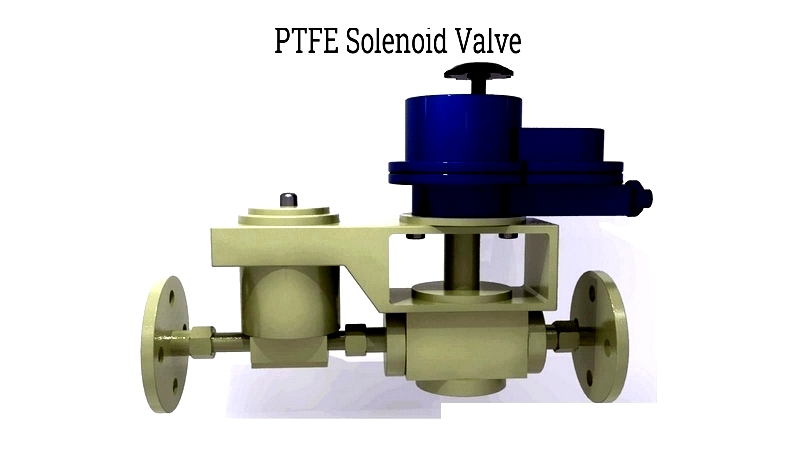

The valve assembly, made from durable materials like stainless steel or PTFE, withstands high pressures and temperatures. A disc connected to the plunger controls flow by sealing against a seat when de-energized.

Selection Considerations:

Key factors include response time, power consumption, pressure range, and compatibility with control systems. Valve configurations (2-way, 3-way, 5-way) determine flow complexity.

Modern valves feature modular coils, IP-rated enclosures, manual overrides, and industry compliance. They're essential in robotics, automotive, food processing, and medical manufacturing where precise flow control matters.

Understanding both electrical and mechanical principles ensures optimal performance, extended lifespan, and safer automation processes.