Introduction

This article provides an in-depth examination of cardboard shredders.

You will explore topics including:

- What a Cardboard Shredder Is

- Types of Cardboard Shredders

- Benefits of Using a Cardboard Shredder

- How Cardboard Shredders Operate

- And more…

Chapter One – What is a Cardboard Shredder?

A cardboard shredder is a machine designed to break down cardboard boxes and sheets into small fragments or strips. These specialized devices convert cardboard into flexible, perforated materials suitable for packaging applications, producing cushioning, flat netting, chips, shreds, or strips. While they share some design similarities with paper shredders, cardboard shredders serve distinct purposes.

The shredding process transforms cardboard into various forms—small chips, elongated strips, perforated sheets, or other configurations—depending on the machine's design and function. This preparation is essential for recycling, enabling cardboard to be repulped, processed, or reused as packaging materials for shipping.

Chapter Two – Types of Cardboard Shredders

Cardboard plays a vital role in packaging, shipping, and product presentation by providing essential protection. With the growth of e-commerce and global logistics, demand for durable cardboard packaging continues to increase. However, widespread cardboard use also presents disposal challenges and landfill concerns.

To address sustainability issues, efficient cardboard recycling and repurposing are crucial. Specialized cardboard shredders and recycling equipment facilitate this process. These machines break down corrugated boxes, sheets, and packing inserts into reusable forms for recycling or compact waste management. Industrial shredders not only reduce waste volume but also help companies cut disposal costs, support environmental initiatives, and comply with regulations. Manufacturers produce various models, primarily categorized by their perforation and shredding functions for material processing and packaging reuse.

Cardboard Shredder Types

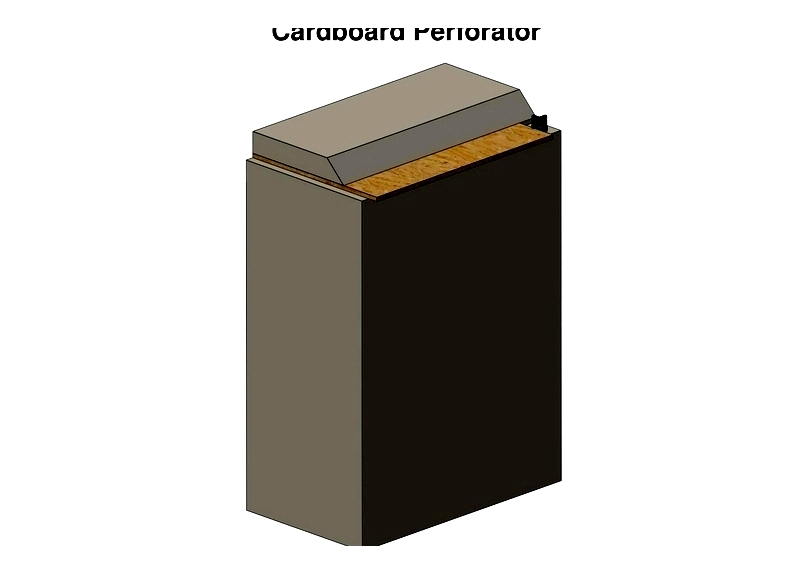

Cardboard Perforator

Specialized perforation machines repurpose cardboard differently from shredders. Equipped with cutting cylinders and blades, perforators create small holes in cardboard without completely cutting through it. This produces flexible "cardboard matting" for use as packing material, void fill, or protective cushioning during shipping.

While perforators don't create small pieces, they offer an effective way to transform used cardboard into reusable packaging, reducing reliance on single-use plastics like bubble wrap. Many businesses now use perforators as sustainable alternatives.

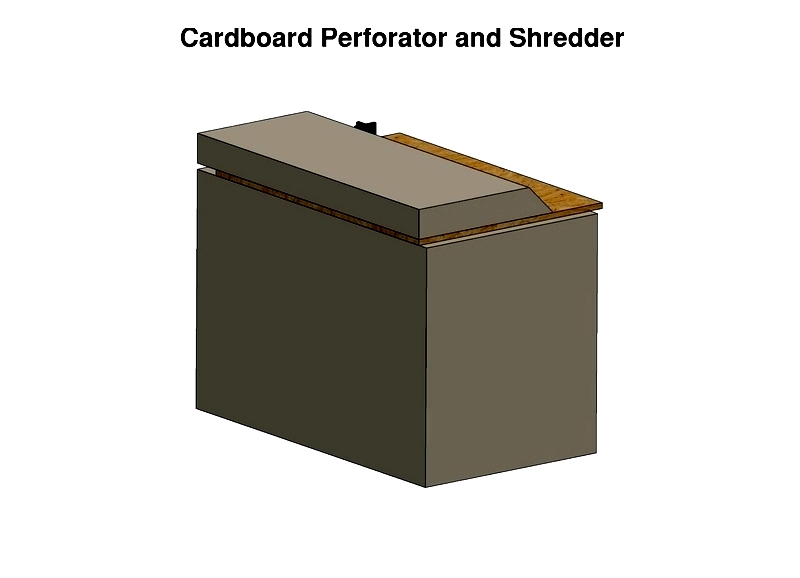

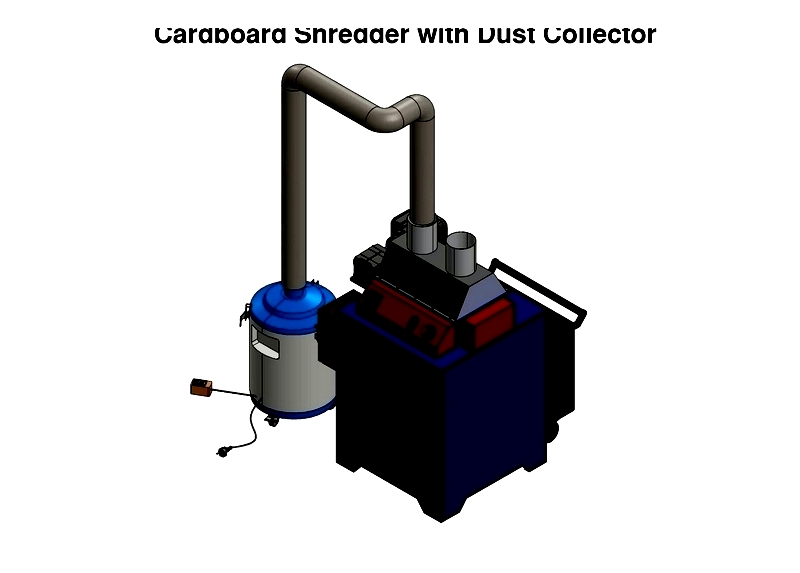

Unlike paper shredding which generates minimal dust, cardboard shredding produces significant dust due to material size and fiber content. Effective dust control measures are necessary to protect workers and equipment.

Dust-controlled shredders feature flanged outlets above cutting blades connected to dust collectors. Internal fans pull dust-laden air through HEPA filters, capturing particles before returning clean air to the environment.

Compressed air periodically cleans filters by counteracting dust flow, preventing clogs. Regular maintenance ensures optimal system performance.

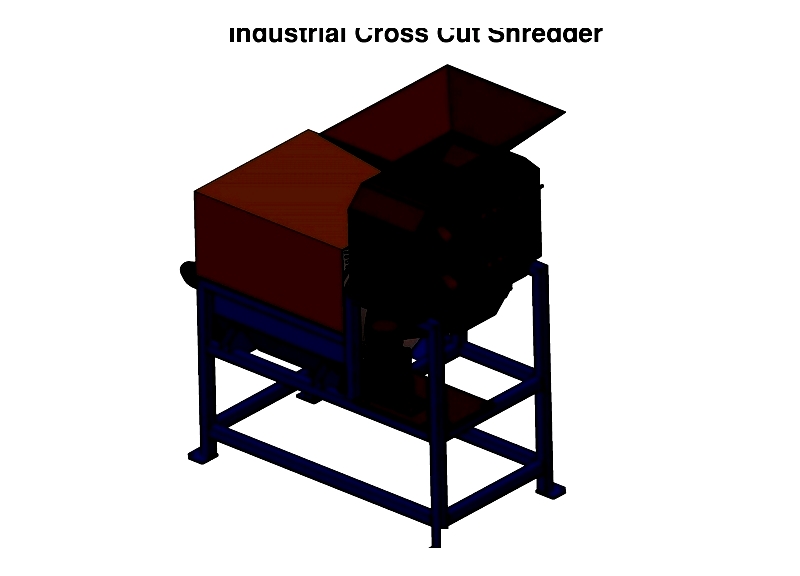

Cross Cut Cardboard Shredders

Cross-cut shredders perform both longitudinal and cross cuts, producing confetti-like pieces that maximize packing density. Particle sizes vary from fractions of an inch to several inches based on machine settings. These industrial shredders are ideal for applications requiring uniform, easily processed material.

High-volume models with conveyor feeding systems handle continuous processing in warehouses and recycling plants. Some designs incorporate paddle wheel crushers to compress cardboard before cutting. Durable alloy cutters withstand constant use. Cross-cut shredders effectively destroy branded packaging or confidential labels, supporting data protection compliance.

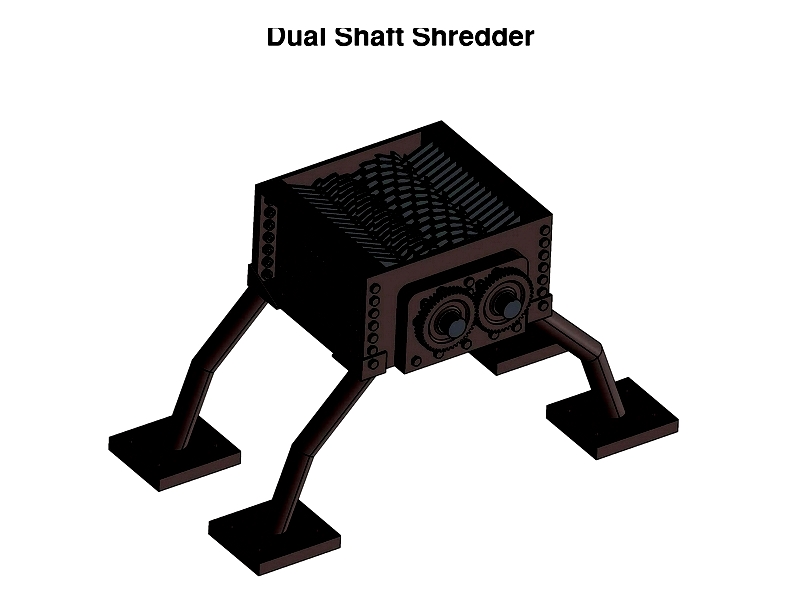

Dual Shaft Shredders

Dual-shaft shredders operate quietly with counter-rotating blades on opposing shafts. This configuration handles thick, heavy-duty materials including multi-wall corrugated boards and laminated packaging. Offering greater cutting power than standard shredders, they process various materials from dense cardboard to pallets.

Most feature single motors, though some have dual motors for increased power. Interlocking blades ensure consistent throughput with minimal jamming. Known for durability and low maintenance, these shredders handle contaminated or mixed waste effectively.

Four Shaft Cardboard Shredders

Four-shaft shredders offer superior reliability, high throughput, and minimal maintenance. Their four rotating blade sets handle demanding environments like recycling facilities and distribution centers.

These powerful machines quickly reduce large volumes into exceptionally small shreds for easy baling or recycling. Advanced models feature smart control systems for customizable output, making them ideal for high-volume operations with sustainability goals.

Full Sized Box Shredders

Industrial box shredders tear entire cardboard boxes into smaller pieces or specific strips for preprocessing before baling. Feeding methods include conveyors, manual feeders, or hoppers.

Three or more high-torque, low-speed rotors draw in and tear material apart. Spiral rotor configurations enhance force and capacity for bulk processing. Slower operation reduces dust and noise. Some models include output sorting screens, dust suppression, and overload sensors for safe operation.

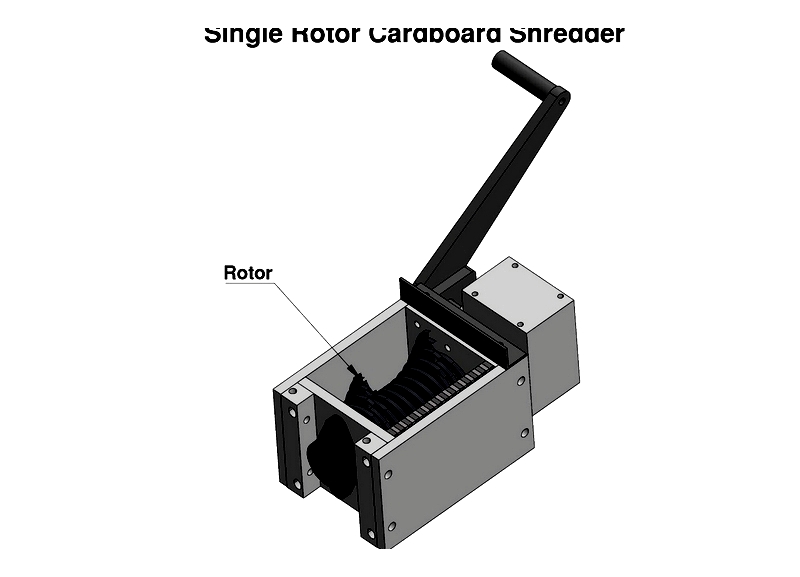

Single Rotor Cardboard Shredders

Compact single rotor shredders process cardboard and lightweight materials. Various feeding mechanisms guide material to the cutting rotor, where blades grind cardboard against a counter-knife. Perforated screens beneath the rotor control output size.

Ideal for commercial applications and mailrooms, these energy-efficient shredders offer controlled particle sizing and easy maintenance, improving recycling rates.

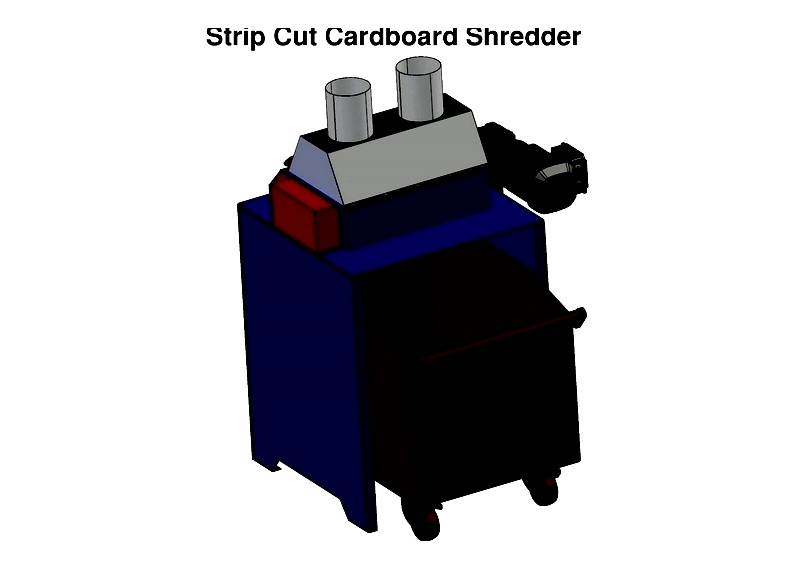

Strip Cut Cardboard Shredders

Similar to paper shredders but more durable, strip cut models produce long ribbons ideal for packing. They destroy cardboard's structural integrity, creating easily compressed strips for shipping protection.

With fewer moving parts, these efficient shredders require less maintenance. Their simple design makes them popular for businesses with moderate disposal needs, supporting sustainability through waste conversion.

Selecting the Right Cardboard Shredder

Consider throughput requirements, cut style, material thickness, dust control, safety features, and space when choosing a shredder. High-volume operations may need dual-shaft or four-shaft models with advanced features, while smaller businesses might prefer single rotor or strip cut models. Many industrial shredders offer customization options like automatic oilers and noise