Introduction

This section showcases pallet rack manufacturers along with examples of their products.

You will discover:

- Pallet Rack Fundamentals

- Different Pallet Rack Varieties

- Pallet Rack Manufacturing Process

- Advantages of Using Pallet Racks

- Additional valuable information

Chapter One – Understanding Pallet Racks

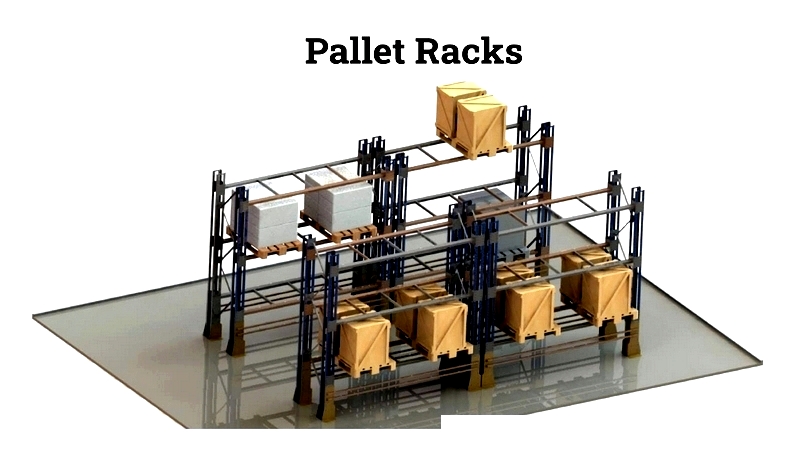

Pallet racks are vertical steel structures specifically engineered for pallet storage. These systems incorporate beams and connectors that are bolted, welded, or clipped together to create a robust framework for storing inventory and equipment. In warehouse settings, pallet racks provide a secure and efficient method for organizing and accessing materials. Their versatile design accommodates diverse products, from consumer goods to industrial machinery.

The popularity of pallet racks stems from their adaptability to various warehousing requirements. Designed for easy accessibility, they represent a premier storage solution. A well-configured pallet racking system arranges pallets in horizontal rows across multiple levels, typically ranging from three to seven tiers based on storage needs. This configuration maximizes vertical space utilization, offering an intelligent and organized approach to inventory storage.

Chapter Two – Pallet Rack Varieties

Pallet racking systems come in multiple configurations, each engineered to meet specific warehouse storage demands. Constructed from high-grade steel, industrial pallet racks provide exceptional durability and load-bearing capacity for storing heavy products and materials. Selecting the appropriate pallet rack system enhances operational efficiency, improves warehouse organization, and ensures workplace safety.

For material handling operations, choosing the right pallet racking solution is crucial for warehouses, distribution centers, and manufacturing facilities. Understanding the various warehouse racking systems—each optimized for storage density, accessibility, or selectivity—helps businesses streamline inventory management and logistics. All professional pallet rack systems incorporate essential features like forklift accessibility, structural reliability, and customization options to safely accommodate diverse pallet sizes and weights.

Pallet Rack Types

Cantilever Racking

Cantilever racking systems specialize in storing long, bulky, or irregularly shaped items unsuitable for conventional pallet racks. These systems feature durable upright columns with reinforced steel arms and horizontal bracing, offering superior weight capacity and stability. Ideal for storing lumber, pipes, or furniture, cantilever racks optimize vertical space in manufacturing environments and tool cribs.

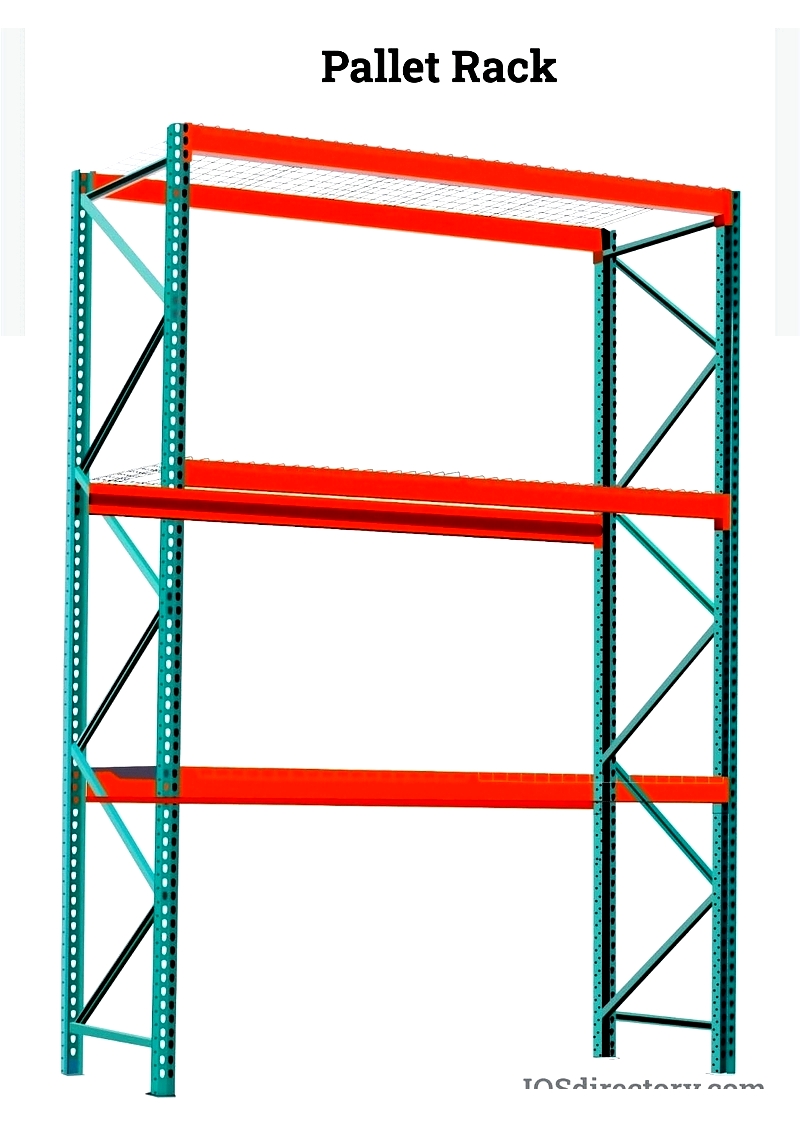

Selective Pallet Racking

As the most common warehouse racking system, selective pallet racking provides direct access to every pallet. This configuration allows immediate retrieval without moving other pallets, making it ideal for facilities with diverse SKUs or FIFO inventory systems. Selective racks enhance order picking efficiency, stock rotation, and inventory visibility while minimizing product damage.

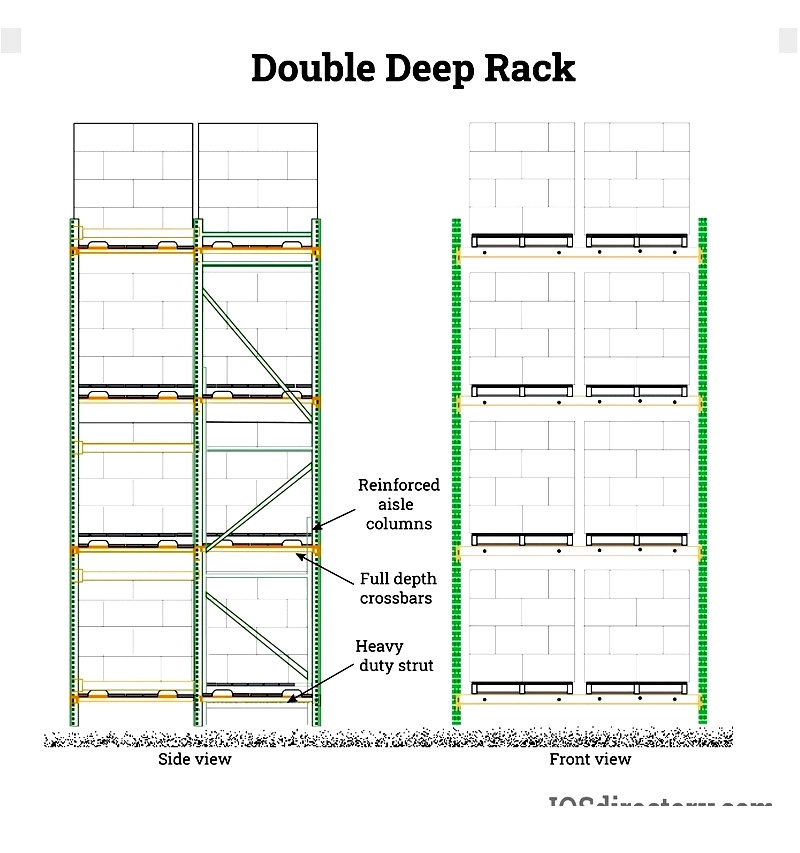

Double Deep Racking

Double deep racking increases storage density by placing two rows of selective racks back-to-back. This configuration requires specialized forklifts for accessing rear pallets and operates on a FILO inventory system. Particularly beneficial for medium-turnover inventory, double deep racking is commonly used in food storage and distribution centers where space optimization is critical.

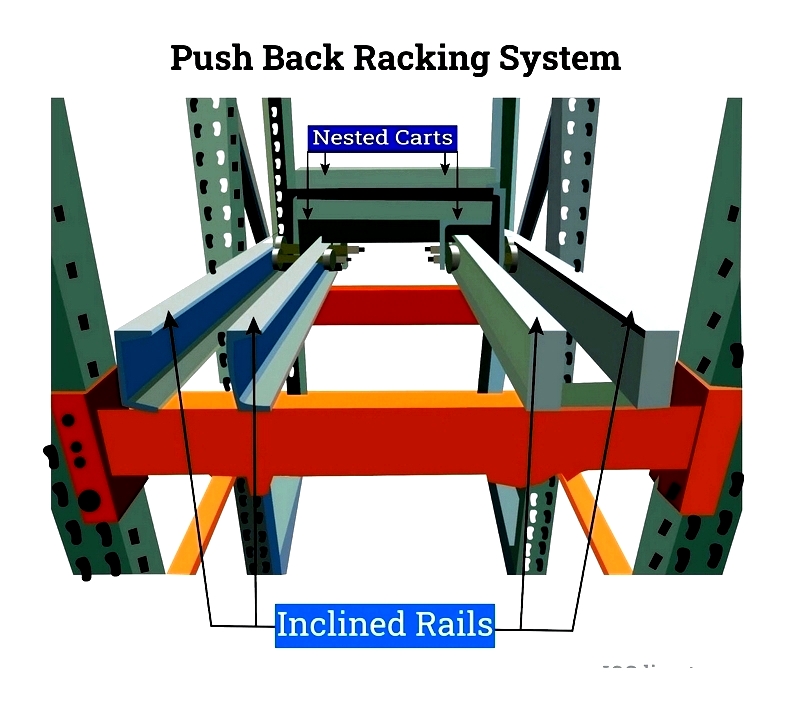

Push Back Racking

Push back racking utilizes inclined rails and nested carts to store multiple pallets in a single lane, operating on a LIFO system. This high-density solution reduces aisle requirements and improves workflow for high-volume operations, making it suitable for batch-picked products or refrigerated goods.

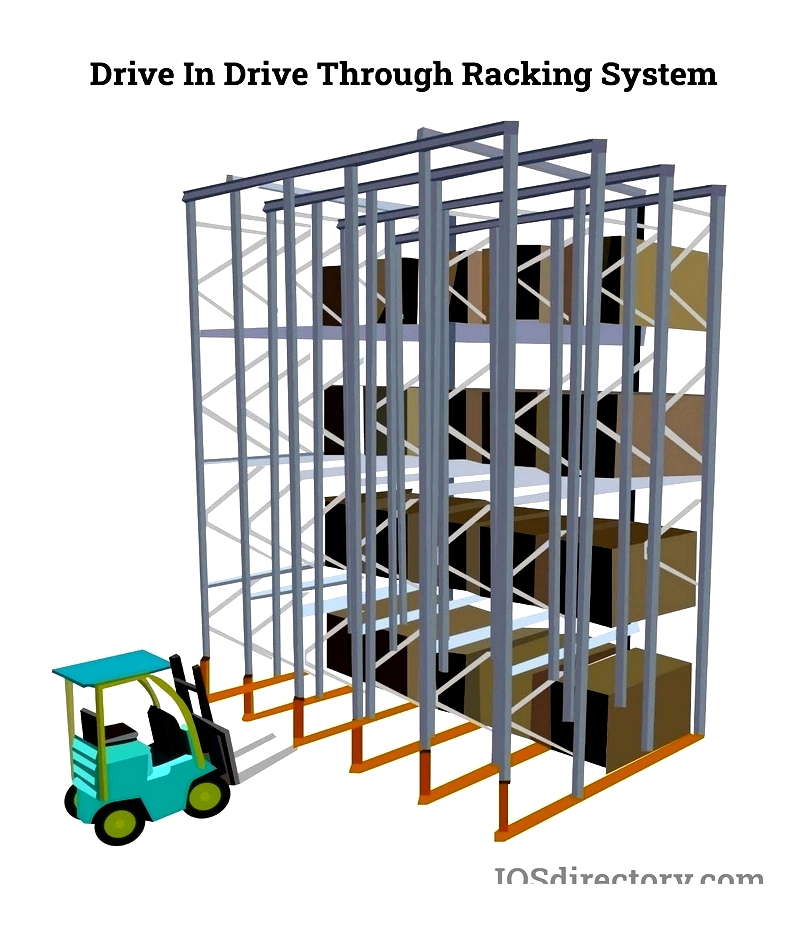

Drive-In/Drive-Through Racking

These high-density systems allow forklifts to drive directly into storage lanes, eliminating internal aisles. Drive-in racks (LIFO) have single access points, while drive-through racks (FIFO) offer dual access. Commonly used in cold storage and food processing, these racks are ideal for bulk storage with limited stock rotation.

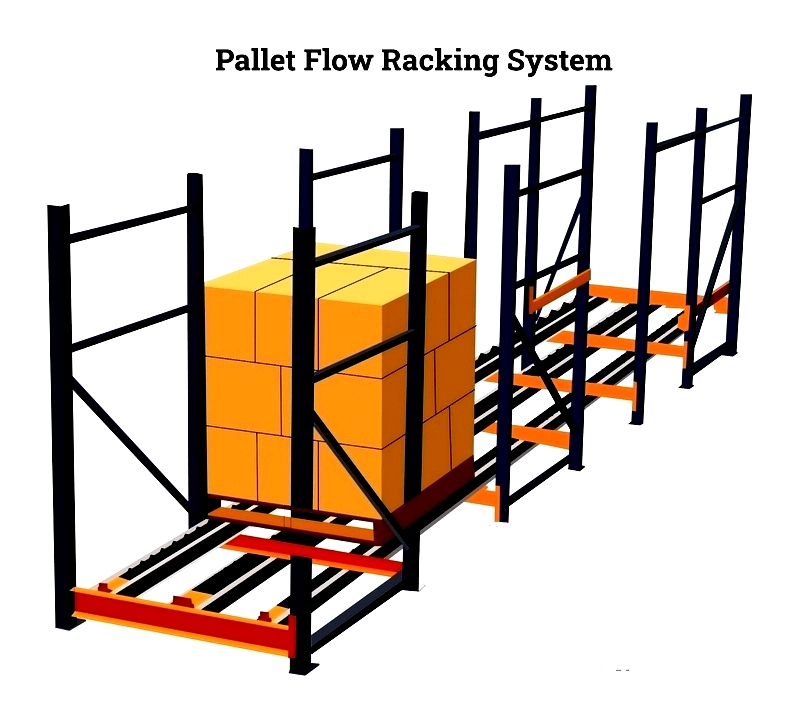

Pallet Flow Racking

Gravity flow racking employs inclined roller tracks for automatic pallet movement, implementing FIFO inventory management. Ideal for perishable goods or high-turnover products, these systems reduce picking time and handling requirements while ensuring proper product rotation for freshness compliance.

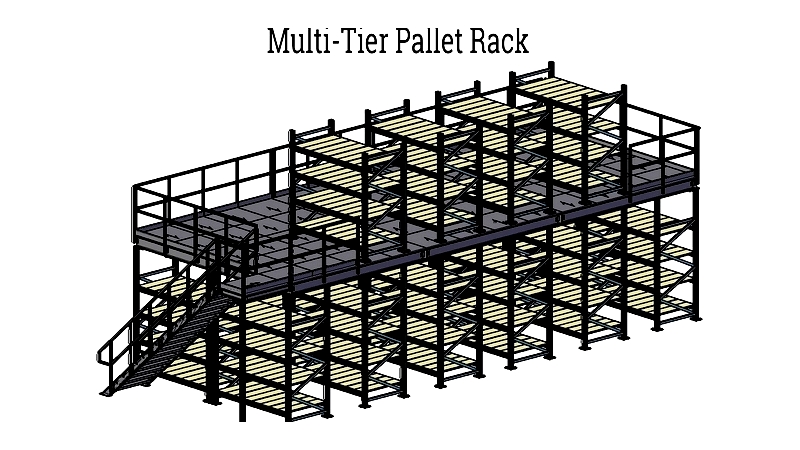

Multi-Tier Racking

Multi-tier systems maximize vertical space in high-bay facilities with integrated shelving and access walkways. Suitable for small parts, pharmaceuticals, and documents, these racks support order picking and inventory control with clear labeling. While not designed for upper-level forklift access, they offer excellent load stability and can be customized for hand-loaded operations.

Racking Accessories

Specialized accessories enhance safety and functionality:

- Anti-Collapse Mesh: Protects against falling objects

- Wire Mesh Decking: Durable shelving surface for small items

- Shelving Panels: Smooth surfaces for boxed goods

- Wooden Decking: Cost-effective for lighter loads

- Dividers: Organize SKUs and prevent mixing

- Pull Out Casters: Enable mobile access

- Barrel Supports: Secure cylindrical containers

- Cable Reel Suspension: Organize wire and hose storage

Custom solutions ensure racks meet specific operational needs and compliance standards.

Chapter Three – Identifying Pallet Racks

Proper identification ensures warehouse safety and efficiency. The connection method between beams and uprights varies by manufacturer and determines system compatibility. Recognition of hardware types and connection styles is essential for maintenance and expansion.

Identification Methods

Teardrop Design

The prevalent North American system features teardrop-shaped holes for tool-free assembly and adjustment. Beams lock securely into uprights, offering flexibility for various loads.

Structural Racking

Heavy-duty C-channel construction with industrial bolts suits high-capacity or seismic-prone facilities. Offers superior durability and impact resistance.