Introduction

This website provides the most comprehensive information about workbenches available online.

You'll discover:

- The definition of a workbench

- Common applications of workbenches

- Workbench design principles

- Different workbench types

- And much more...

Chapter One – Understanding Workbenches

A workbench is a sturdy, flat surface available in various sizes, designed for specific tasks. These range from complex engineering setups for machining and precision work to finely crafted wooden tables for woodworking, metalworking, and design projects.

High-quality workbenches feature robust supports capable of handling heavy machinery and tools. While similar to workstations, workbenches typically offer larger surfaces for diverse activities, whereas workstations are more specialized for production or assembly lines.

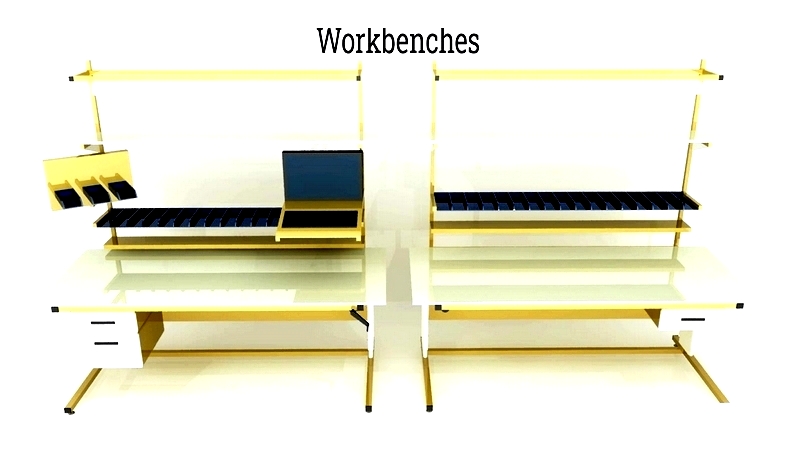

Bench Depot's example below shows a versatile workbench with lighting, component storage, leveling guides, and other specialized features.

Traditional workbenches have evolved into modern designs using materials like stainless steel, aluminum, and steel. These contemporary versions feature smooth, easy-to-clean surfaces that enhance workspace efficiency.

Chapter Two – Workbench Applications

Workbenches serve as essential components across industries including manufacturing, engineering, electronics, woodworking, and laboratories. They provide stable, ergonomic surfaces for tasks ranging from assembly to product testing. Customizable solutions help businesses boost productivity while meeting safety standards and adapting to operational changes.

Workbench Tool Support Systems

Industrial workbenches primarily support heavy tools and specialized equipment for finishing, assembly, maintenance, and repairs. Heavy-duty models typically hold over 1600 lbs (750 kg), accommodating power tools, vises, and testing equipment. Modular designs often include built-in storage, power options, and tool racks to optimize workflow.

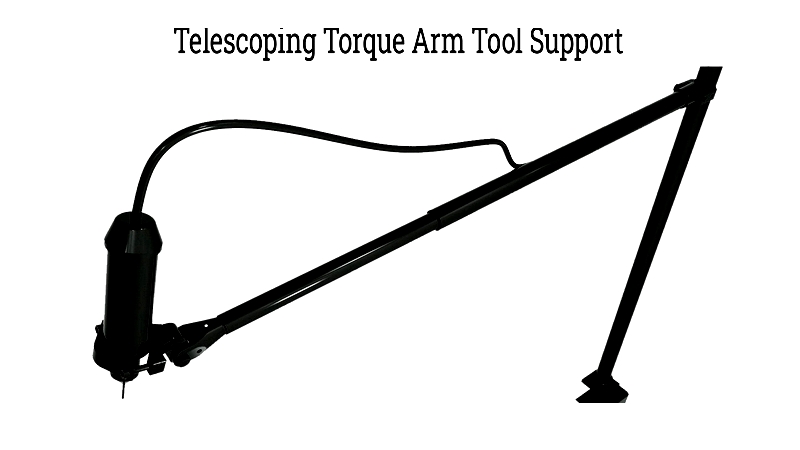

Advanced systems feature ergonomic designs with anti-static surfaces, vibration control, and height adjustments. Support accessories like articulated arms and tool organizers help manage power tools while reducing operator fatigue. Torque arm systems come in three main types:

- Telescoping Torque Arm – Adjustable length with 360-degree rotation capability, suitable for varying workspace needs.

- Glider Torque Arm – Smooth-gliding design provides steady tool support while reducing strain injuries.

- Articulated Torque Arm – Multiple joints offer greater motion range and precision for intricate tasks.

Workbench Construction and Durability

Industrial-grade workbenches withstand heavy use in demanding environments. Premium models feature durable surfaces like hardwood, laminate, or resin, often with steel frames for added strength. These worktops resist abrasions, chemicals, and impacts for long-term reliability.

Selection considerations include load capacity, modularity, mobility options, and specialized features. Customizable systems can incorporate shelving, lighting, power strips, and computer mounts to suit specific needs.

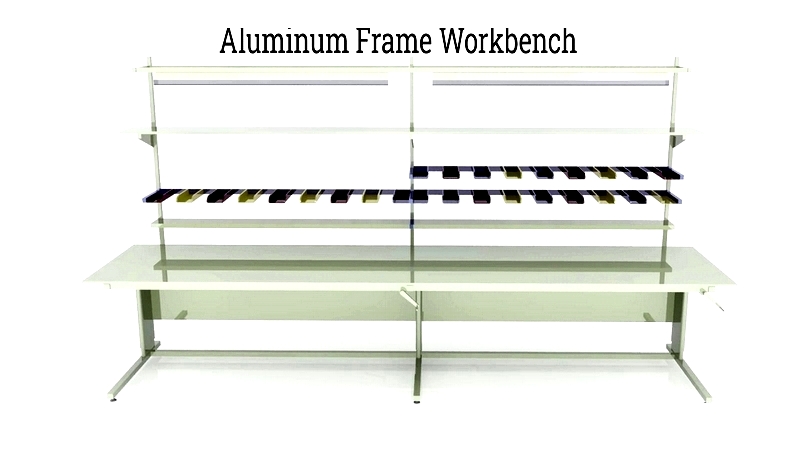

The steel frame workbench below demonstrates industrial-grade durability for high-performance applications.

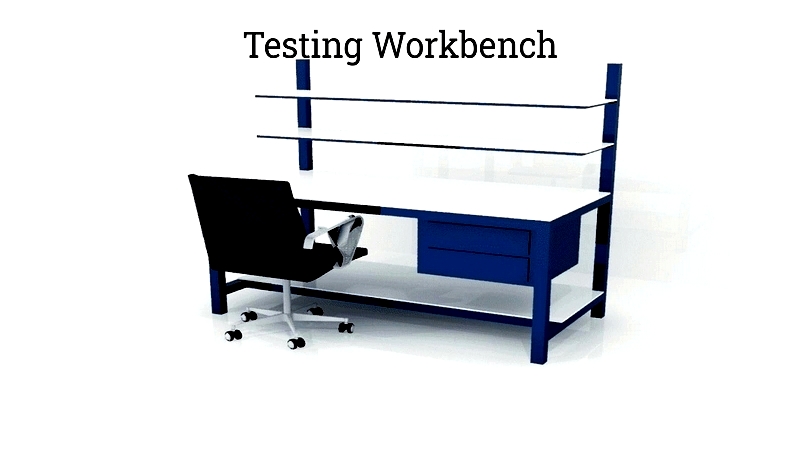

Product Testing Applications

Specialized testing workbenches feature anti-static protection, secure grounding, and power units for electronics and sensitive devices. These benches support precise measurements and diagnostics in manufacturing and research environments.

Assembly Workbench Integration

Production-line workbenches optimize ergonomics and workflow with adjustable heights, task lighting, and tool organization. Features like anti-fatigue mats and modular storage enhance efficiency in repetitive assembly tasks.

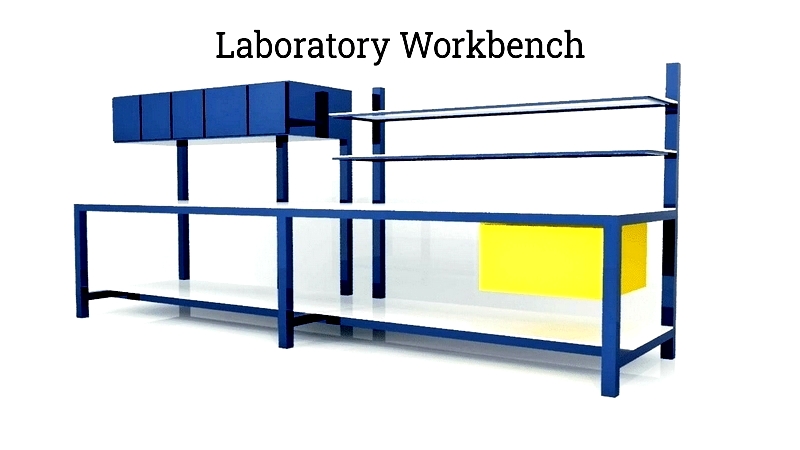

Laboratory Workbench Solutions

Lab workbenches incorporate chemical-resistant surfaces, integrated sinks, and specialized storage for scientific work. These designs maintain hygiene standards while supporting precision equipment.

Selecting the Right Workbench

Consider load requirements, workspace limitations, ergonomic needs, and industry standards when choosing a workbench. Industrial users may prioritize ESD protection, while labs focus on chemical resistance. Understanding your workflow helps identify the best solution for your specific requirements.