Introduction

This is the internet's most comprehensive guide to wire forming.

You will learn:

- What is Wire Forming?

- How Wire Forming Works

- Different Types of Wire Forming

- Applications of Wire Formed Products

- And much more...

Chapter One – What is Wire Forming?

Wire forming involves reshaping wire through various techniques like bending, swaging, piercing, chamfering, and shearing. These methods allow for creating diverse shapes and configurations. The process begins with coiled wire that's first straightened before being formed into the desired shape.

Common metals used in wire forming include steel, brass, stainless steel, copper, aluminum, and various alloys. Wire diameters typically range from 0.5 mm to 6.5 mm (1/64 inch to 0.25 inch) and can be shaped into both two-dimensional and three-dimensional forms.

Wire forming equipment varies from basic hand tools to sophisticated CNC machines. The process may also include finishing techniques like coating to enhance product durability in challenging environments.

Chapter Two - Methods Used for Wire Forming

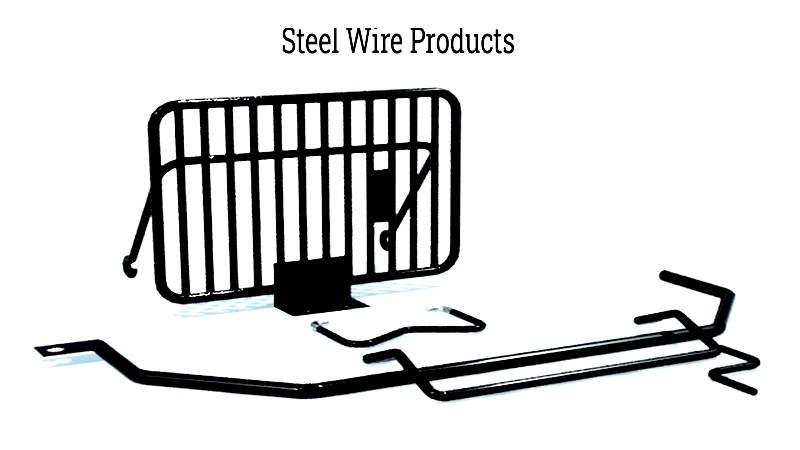

Wire forming is crucial in metal fabrication, producing custom components for various applications. Equipment falls into manual or automatic categories. Manual machines include hand-operated and semi-automatic models, while modern industrial settings use automatic CNC machines for efficient, precise production of wire forms, springs, and fasteners.

Drawing Method

Before forming, raw wire undergoes drawing to achieve the desired diameter and properties. This process pulls wire through dies, reducing diameter while increasing tensile strength and uniformity, resulting in high-quality wire for subsequent operations.

The Drawing Process

- Install the Drawplate: Securely install the drawplate on specialized drawbenches.

- Tapering: Taper wire ends for smooth die entry.

- Annealing: Heat treatment prevents breakage during drawing.

- Lubrication: Apply lubricants to reduce friction and improve surface finish.

- Pull Through: Mechanically pull wire through dies to achieve required gauge.

Methods Used to Form Wire

Various specialized processes create specific wire shapes for industries like electronics, automotive, and medical devices.

Manual Wire Forming

The traditional method uses hand-operated bending machines with levers and spindles for shaping wire into simple or complex bends.

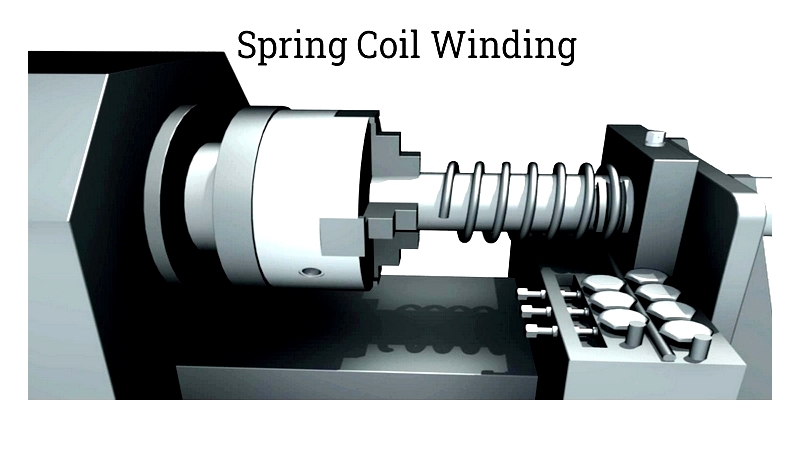

Coil Wire Forming

Essential for spring manufacturing, this method winds wire around mandrels to create compression, extension, and torsion springs with precise electrical properties.

Roll Wire Forming

This cost-effective method uses rollers to form wire into profiles with enhanced strength and smooth edges for automotive and industrial applications.

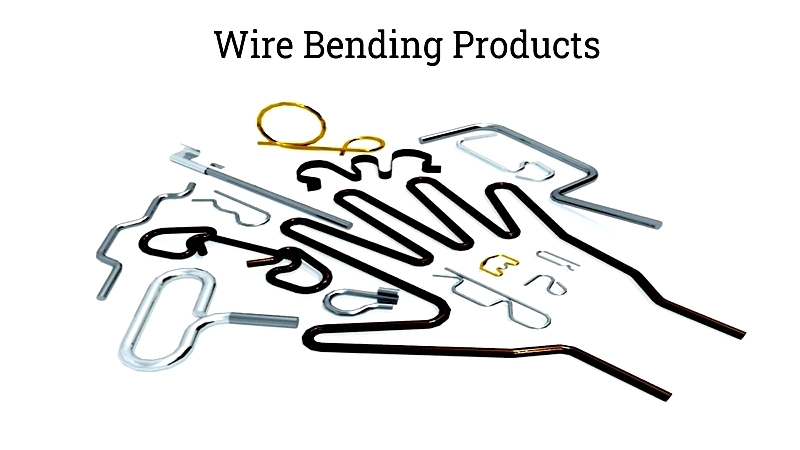

Bending Wire Forming

Creates 2D and 3D forms from various wire diameters with minimal waste, using tools ranging from hand tools to CNC benders.

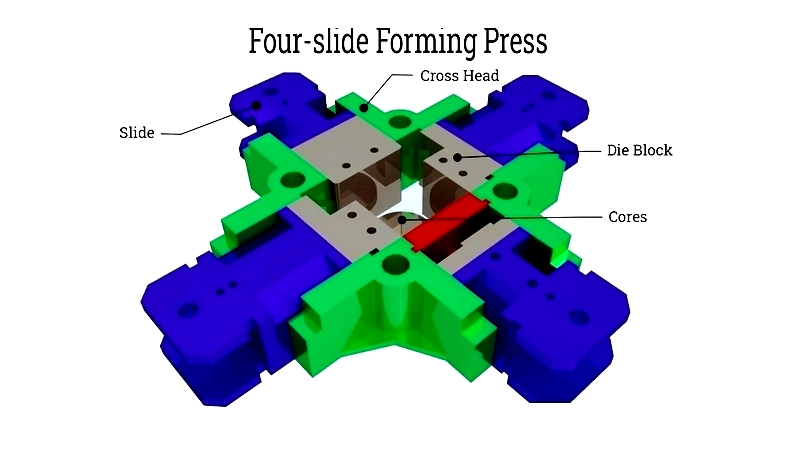

Fourslide Wire Forming

Uses multi-directional cams to create complex shapes efficiently for mass production of electrical components and clips.

Hydraulic Wire Forming

Powerful hydraulic motors shape heavy-gauge wire for demanding applications like automotive suspension systems.

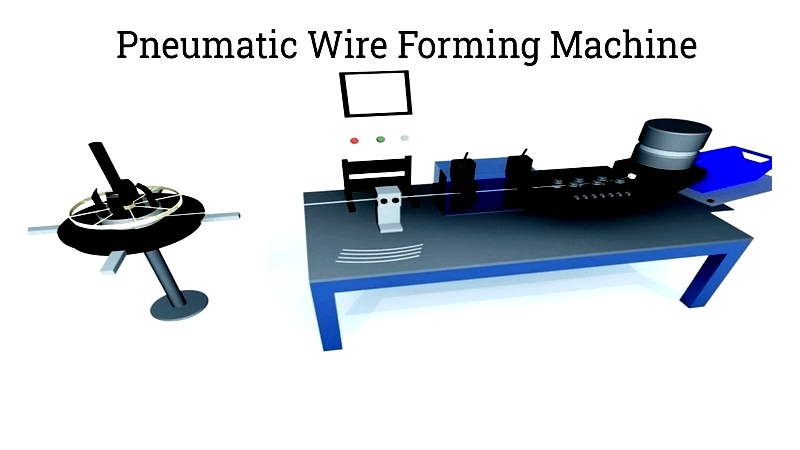

Pneumatic Wire Forming

Compressed air powers rapid forming of uniform parts like fasteners and hooks.

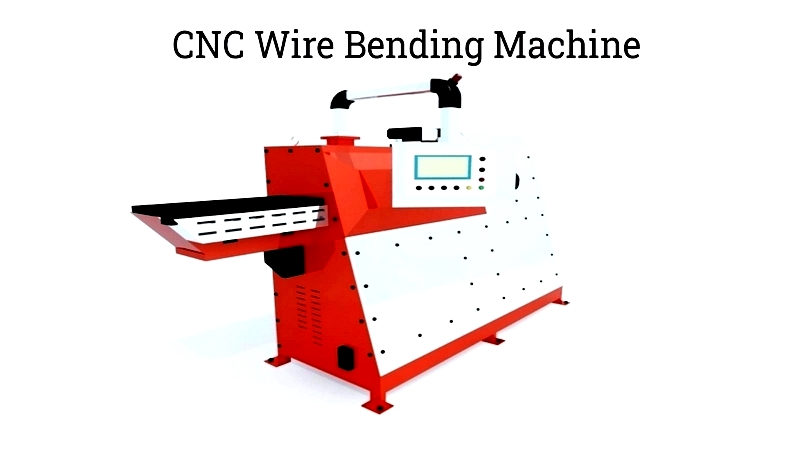

CNC Wire Bending

Automated machines provide precision bending for custom forms and prototypes in various materials.

Wire Ends and Interior Geometries

Specialized finishing enhances part functionality and safety.

Machine Cut End

Produces clean cuts with minimal burrs for various applications.

Chamfered End

Creates smooth, angled edges for safety and easier assembly.

Winging

Forms wing-shaped ends for better component retention.

Pierced Swaging

Creates expanded ends with center holes for electrical contacts.

Custom Shaped Hole

Produces specialized openings for unique mounting requirements.

Chisel Point and Turned End

Forms pointed ends for pins and probes.

Ball End

Creates rounded ends for decorative and mechanical applications.

Groove

Machines circumferential grooves for locking mechanisms.

Cold Heading

Forms robust wire ends for screws and fasteners.

Wire Forming Tolerances

Precision tolerances (±0.01 per bend) ensure proper fit and function in critical applications.