Introduction

This article provides comprehensive insights into titanium metal and its alloys.

You will learn about various topics including:

- What is titanium metal?

- Properties of titanium metal

- Compounds and grades of titanium metal

- Fabrication processes

- And much more...

Chapter 1: Understanding Titanium metal

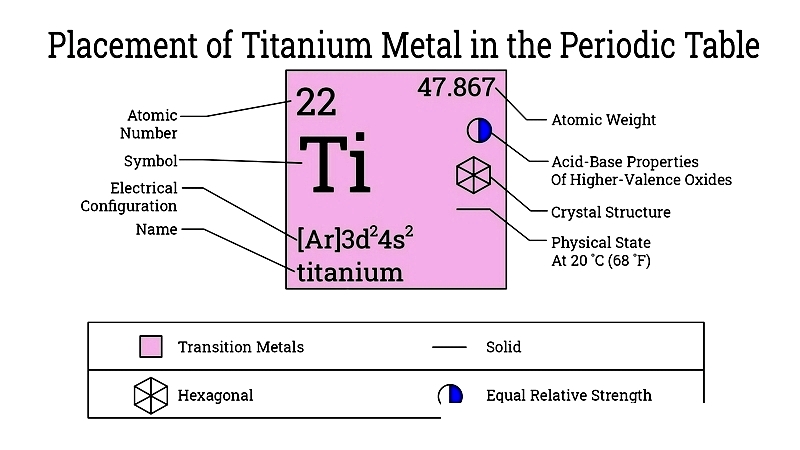

Titanium, symbolized as "Ti" with atomic number 22, is a chemical element with an atomic mass of 47.9. As the ninth most abundant element in Earth's crust, its primary sources include minerals like rutile (titanium dioxide), ilmenite (iron titanium oxide), and sphene (calcium titanium silicate).

Renowned for its high strength-to-weight ratio, ductility, corrosion resistance, and biocompatibility, titanium is widely used in various industries, particularly for medical implants. Its exceptional strength and resistance to heat, water, and salt complement its lightweight properties, making it ideal for applications ranging from jewelry to medical devices, aircraft, and marine vessels.

Titanium alloys retain the core properties of pure titanium while offering additional characteristics like flexibility and malleability, expanding their applications. Pure titanium comes in six grades (1, 2, 3, 4, 7, and 11), which serve as the foundation for four main titanium alloys. These alloys incorporate elements such as aluminum, molybdenum, vanadium, niobium, tantalum, zirconium, manganese, iron, chromium, cobalt, nickel, and copper. The most notable titanium alloys include Ti 6Al-4V, Ti 6Al ELI, Ti 3Al 2.5V, and Ti 5Al-2.5Sn.

Commercially available titanium and its alloys from metalmen

Commercially available titanium and its alloys from metalmen

Periodic Table Location

Titanium is the first element in the D-block of the periodic table. With 22 electrons and 22 protons, it belongs to period 4, group 4, characterized by its electron configuration: 1s² 2s² 2p⁶ 3s² 3p⁶ 3d² 4s². These electrons, especially those in the fourth orbital, contribute to titanium's chemical bonding capabilities and diverse properties.

Natural Presence

Titanium constitutes approximately 0.63% of Earth's crust, with nearly 90% found in ilmenite minerals (iron titanium oxides, FeTiO₃). The remaining titanium is distributed among other minerals like anatase, perovskite, rutile, leucoxene, and sphene.

Extracting titanium involves mining from sand, rocks, soil, and clay using open-pit or underground methods, depending on deposit location. Techniques such as crushing, grinding, screening, magnetic separation, and flotation are employed to enhance titanium content and remove impurities.

Oxidation States and Isotopes

Titanium has five stable isotopes: titanium-46, titanium-47, titanium-48, titanium-49, and titanium-50. The most abundant, titanium-48, accounts for 73.8% of naturally occurring titanium. Additionally, 21 radioisotopes have been identified, with the most stable being titanium-44 (half-life of 63 years), titanium-45 (184.8 minutes), titanium-51 (5.76 minutes), and titanium-52 (1.7 minutes).

Titanium-48 remains the most prevalent isotope, making up 73.8% of the element's natural occurrence.

Titanium Isotopes

Titanium-46 (46Ti) 8% abundant

Titanium-47 (47Ti) 7.8% abundant

Titanium-48 (48Ti) 73.8% abundant

Titanium-49 (49Ti) 5.5% abundant

Titanium-50 (50Ti) 5.3% abundant

Titanium typically exhibits an oxidation state of +4, making it resistant to further oxidation in chemical reactions. As a transition metal, it can display multiple oxidation states: +2, +3, and +4, with +4 and +2 being the most stable.

When exposed to air, titanium and its alloys quickly form a titanium oxide layer. While titanium reacts readily with air, its reaction with water is slower due to this protective oxide coating. Initially 1-2 nm thick, the coating can grow to 25 nm over four years, providing titanium's notable corrosion resistance.

Titanium has 21 radioisotopes with atomic weights ranging from 39.99 u (titanium-40) to 57.966 u (titanium-58), each with distinct half-lives. The most stable include titanium-44, titanium-45, titanium-51, and titanium-52.

Symbol

Spin

Club heads crafted from Titanium offered by TMS Titanium, Inc.

Club heads crafted from Titanium offered by TMS Titanium, Inc.