Introduction

This article provides information about push pull cable controls and their applications.

You will learn about various topics including:

- What is a Push Pull Cable

- How Push Pull Cables are Manufactured

- Applications of Push Pull Cables

- Factors in Push Pull Cable Control Installation

- And more...

Chapter One – What is a Push Pull Cable Control?

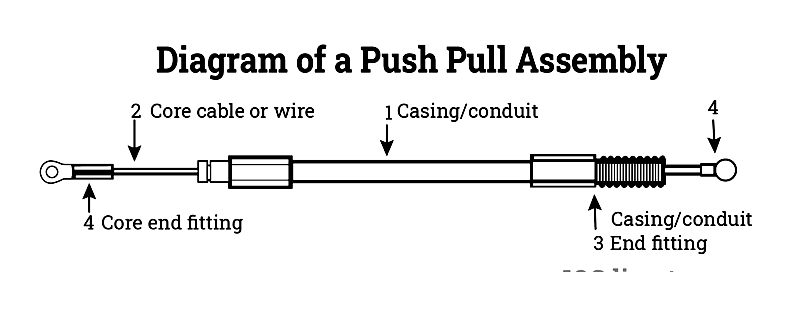

A push-pull cable control is designed for precise, multi-directional mechanical motion management. Available in various configurations, these controls are versatile for numerous applications. They are widely used in automotive, aerospace, and heavy machinery industries to adjust and operate different mechanisms.

These cable systems consist of two specific cables: one engages a device while the other disengages it. Despite being called a "push" cable, it primarily functions through pulling, similar to the second cable which also relies on pulling action.

While push-pull assemblies serve a fundamental purpose, they are crucial in the development and design of mechanical components and analog systems. For equipment actuation requiring physical force, push-pull control cables often provide the optimal solution.

The design process begins with evaluating the workload in push mode. The inner wire may encounter resistance, potentially causing bending or buckling, especially when extending beyond the conduit. Increasing the inner wire's diameter can address this issue, enabling it to withstand the workload effectively.

Engineers must consider multiple factors when designing push-pull assemblies, including inner wire behavior in push mode. Although these assemblies operate on simple principles, precise calculations are essential for optimal performance.

Chapter Two – How Push Pull Assemblies are Manufactured

The design and production of push-pull assemblies are crucial for effective machine design and reliable performance across industries. Well-engineered push-pull assemblies, also known as control cable assemblies, ensure smooth operation of mechanical or electromechanical functions with enhanced safety, precision, and longevity. These assemblies play a vital role in managing equipment functions like acceleration, actuation, braking, and throttling, making them essential components in automotive, industrial, marine, and aerospace sectors.

During the design phase, engineers must carefully consider each component and material selection. Any defect in assembly construction can significantly impact system performance, reliability, and safety. While specialized push-pull assemblies exist—from flexible drive cables to custom control cable assemblies—certain key components and production techniques are common across all types and applications.

The Manufacturing Process of Push Pull Assemblies

Casing of the Assembly

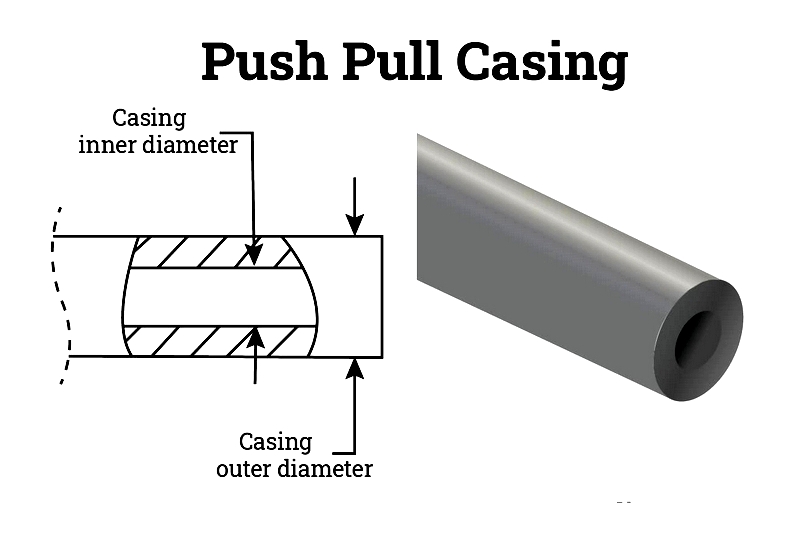

The casing, or conduit, provides a protective pathway for the inner cable. It ensures proper guidance and protection even in challenging environments. Manufacturers use various materials for casings—including galvanized steel, nylon, plastic tubing, or spiral-wrapped wire—based on requirements for flexibility, abrasion resistance, chemical resistance, and strength. High-performance plastic or steel casings are often used in applications exposed to vibration, extreme temperatures, or corrosive elements.

The casing features an engineered inner diameter to house the moving cable, while its outer diameter provides mechanical strength and durability. Specialized end fittings can be added to enhance operational ease and ensure precise interface with controls. A well-made conduit reduces friction, prevents cable kinking, and extends the assembly's lifespan.

Bulkhead Terminal

The bulkhead terminal is securely crimped or swaged onto the casing, providing robust anchoring to panels or surfaces. Typically made from high-strength materials like steel or brass, these terminals withstand demanding loads and resist corrosion. Proper installation ensures accurate cable actuation and prevents unwanted movement, particularly important in safety-critical applications.

Push Pull Assembly Inner Wire

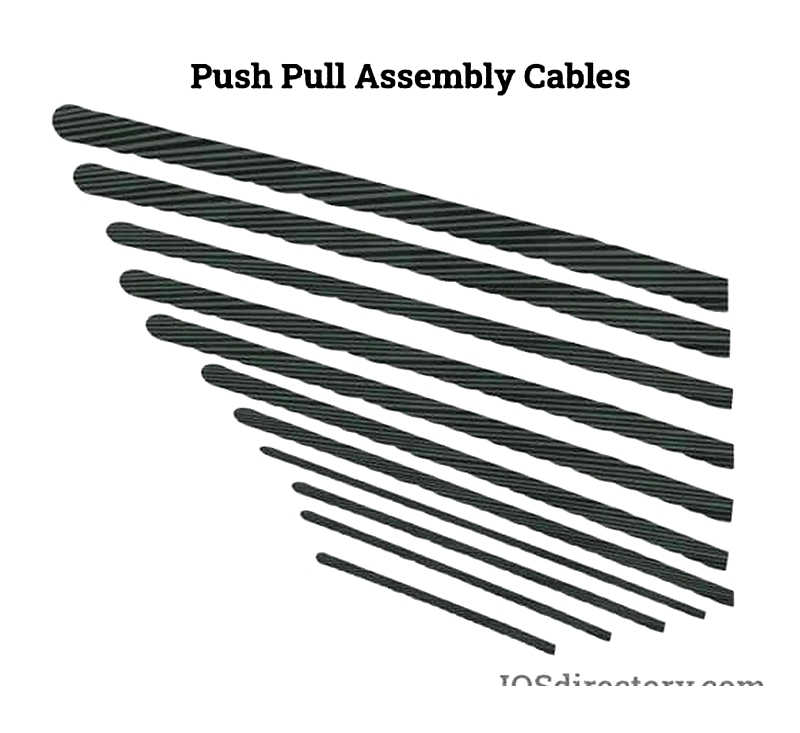

Selecting the proper inner wire is fundamental to assembly performance. Even in light-duty applications, a robust inner cable is necessary for smooth operation. Material selection—typically stainless steel or galvanized steel—depends on mechanical properties like tensile strength and corrosion resistance. The pull position, where maximum loads occur, largely determines the appropriate cable configuration.

Flexibility is another critical factor. Most high-quality assemblies use 7 x 19 or 7 x 7 cable configurations, offering optimal bending capability without sacrificing strength. In contrast, 1 x 19 wire provides higher rigidity but is less flexible.

Managing friction within the conduit is key to maximizing lifespan and minimizing wear. Uncoated wires are commonly used as they generate lower friction than coated alternatives, enhancing durability and reducing maintenance costs.

Travel distance—the span between conduit end and cable bearing surface—should ideally be kept under five inches to reduce friction, prevent buckling, and maintain responsive operation.

Inner wires are manufactured by winding strands in a helical pattern around a central core. Cables with higher strand counts offer increased flexibility and load handling, making them suitable for dynamic applications. Solid core wires may be chosen where added stiffness is needed for precise actuation.

Fittings and Terminals

Fittings and terminals provide secure connections and prevent system deflection. These components enable precise adjustment and operation of mechanisms, with selection depending on application—whether for throttle controls, industrial equipment, or marine systems.

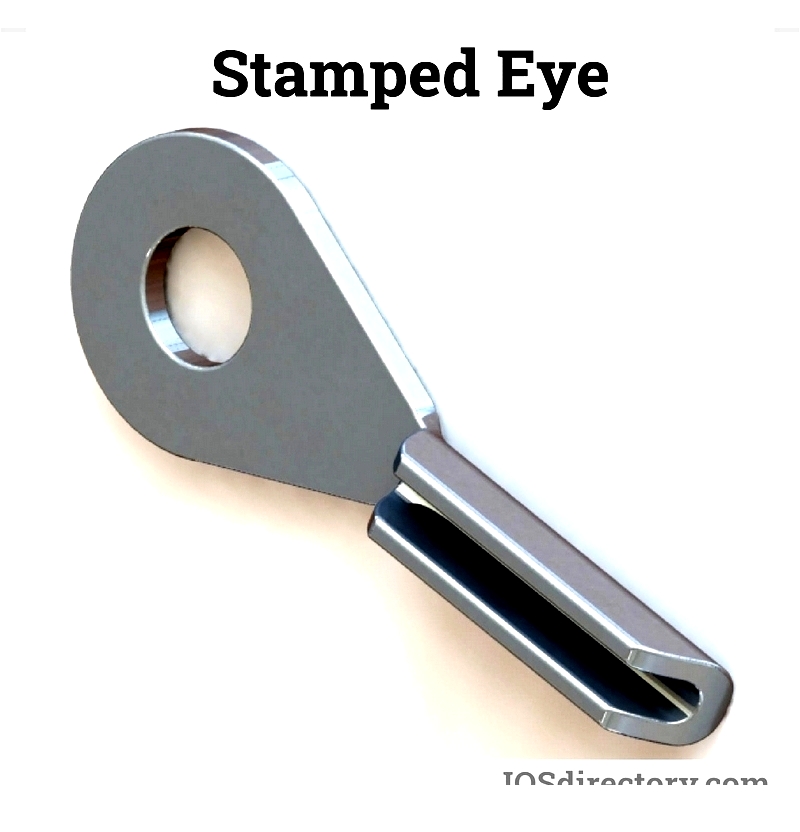

Stamped Eyes

Stamped eyes are common terminals compatible with various control cables. They are pressed using hydraulic swaging equipment, creating strong, vibration-resistant connections for automotive and industrial applications.

Ball End

Ball end fittings match various cable diameters in throttle or brake systems. Swaged onto the inner cable, they provide smooth pivoting action and secure connections to levers, optimizing responsiveness.

Ball Shanks

Ball shank fittings serve in numerous applications from throttle controls to marine steering. They protect cables from abrasion, facilitate smooth rotation, and extend service life in high-use scenarios.

Thimbles

Thimbles reinforce cable loops, preventing wear and maintaining integrity. These robust fittings protect against sharp bends and abrasion, especially important in lifting and industrial systems.

Threaded Stud

Threaded studs allow direct attachment to machine fixtures. Available in various sizes, these rugged fittings are swaged onto cables, commonly used in manufacturing and automotive controls.

Strap Fork or Eye

Strap fork and eye fittings are essential for pull actuation. Their slim profile makes them ideal for compact machinery and tight-space applications.