Introduction

This comprehensive guide covers all aspects of industrial vacuum cleaners and their applications.

You will discover:

- The definition of Industrial Vacuum Cleaners

- Their operational principles

- Different varieties available

- Practical applications

- Additional valuable information

Chapter 1: Understanding Industrial Vacuum Cleaners

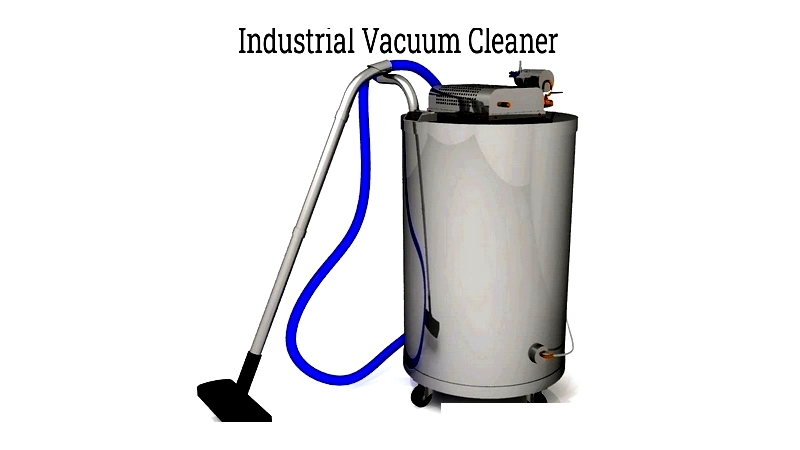

Industrial vacuum cleaners are powerful machines that effectively remove dirt, debris, and various solid/liquid substances from surfaces. They're widely used in construction sites, manufacturing plants, metalworking facilities, woodworking shops, and warehouses where substantial waste generation occurs.

Modern industrial operations rely on these cleaners for recycling, material recovery, and spill control. Designed for heavy-duty applications, they outperform domestic models by handling challenging materials like abrasive substances, coolant residues, oil mists, explosive dust, fine powders, metal shavings, and welding fumes.

Chapter 2: Industrial Vacuum Cleaner Mechanics

Industrial vacuum cleaners function through air pressure differentials. By creating a low-pressure zone, they draw in surrounding air along with contaminants. This fundamental physics principle enables effective removal of dust, debris, and hazardous particles in industrial settings.

These machines employ fans or centrifugal pumps to generate suction. Their motors, available in single or three-phase configurations, deliver varying power levels to meet different cleaning demands. Three-phase motors particularly excel in heavy-duty applications across manufacturing plants and warehouses.

The adaptable design accommodates numerous specialized attachments. Carpet cleaning models feature agitators, while auto detailing units include compact tools for tight spaces. Continuous-duty models boast large-capacity chambers for uninterrupted operation in commercial environments.

Performance varies by technical specifications including airflow rate, filtration type, storage capacity, and power source. Selection depends on application needs across manufacturing, food processing, pharmaceuticals, or cleanrooms. Airflow characteristics determine suction strength for handling different debris types and volumes.

Modern filtration systems are tailored to contaminant types. Water filtration traps dust in liquid, while HEPA filters capture microscopic particles. ULPA filters offer superior filtration, and activated charcoal neutralizes odors in sensitive environments.

Cyclonic separation extends filter life by removing larger particles first. The emergence of robotic cleaners introduces automation, with programmable units that navigate facilities independently while providing performance analytics.

Selection criteria should include application type, suction requirements, portability, filtration needs, regulatory compliance, noise levels, and operational costs. Proper maintenance ensures efficiency, longevity, and workplace safety. For specialized needs, consulting industry suppliers helps identify optimal solutions.