Introduction

This section covers various types of scales and their manufacturers.

You will learn about:

- Different types of scales

- How scales function

- Applications for various scale types

- Additional relevant information

Chapter 1: Understanding Different Types of Scales

Scales are classified according to the materials they measure and their intended purpose. They primarily fall into three categories: mechanical, digital, and analytical scales. Digital scales have gained widespread popularity for their exceptional precision.

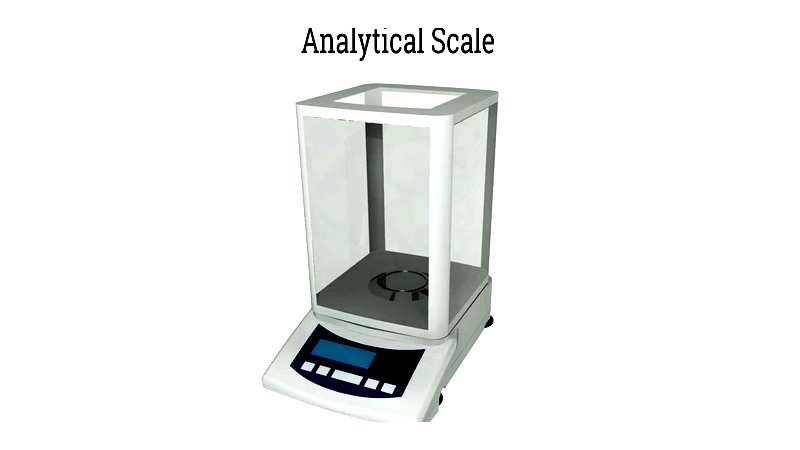

Mechanical scales represent traditional weighing devices that operate using spring or lever mechanisms, commonly used in both residential and commercial settings. The invention of load cells during the first industrial revolution revolutionized the weighing industry, making digital scales the most reliable choice. In research laboratories and chemical fields, analytical scales are essential for measuring minute quantities with extreme precision, utilizing electromagnetic force restoration (EMFR) technology to measure weights as small as a milligram.

Scales operate on the principle of gravitational force acting on objects. This concept is applied universally for weighing food, chemicals, and people, providing standardized measurements. A typical scale determines weight by measuring the force generated by mass under gravitational acceleration.

For ultra-precise measurements, comparative techniques called balance measurements are employed, where an object's weight is compared against a known reference. These highly accurate scales are crucial for scientific and technical applications.

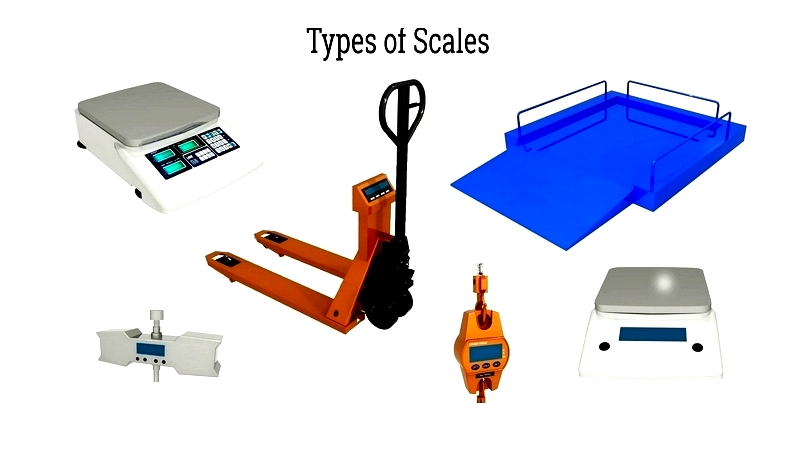

Chapter 2: Types of Scales

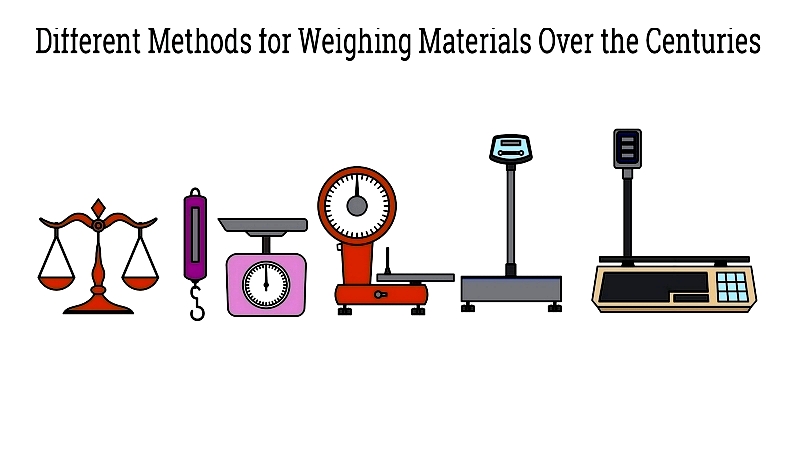

The two primary scale categories are digital and mechanical. Throughout history, weighing scales have been vital across industries and civilizations, from commercial trade to laboratory analysis. While modern society predominantly uses metric systems, different cultures and industries have developed unique weighing methods for manufacturing, research, food processing, and logistics.

Mechanical weighing devices depend on gravitational force, using springs, levers, or counterbalances to determine weight. Ancient civilizations employed balance scales to compare unknown masses against known references, leading to more accurate designs over time. Modern mechanical scales, such as those based on Hooke's Law from the 18th century, remain valued for their durability and suitability in harsh environments.

Digital scales emerged in the late 20th century, utilizing electrical resistance to measure force and display digital readouts. These scales employ precision load cells and strain gauges that adjust resistance proportionally to weight. Their speed, accuracy, and ease of use have transformed weighing technology for shipping, laboratories, and retail applications.

For measurements requiring extreme precision below a tenth of a gram, analytical balances with EMFR technology were developed. Introduced in 1945 by Mettler Toledo, these scientific balances achieve microgram-level accuracy essential for chemistry, research, and quality control.

Contemporary innovations include touch screen systems, smart scales, and IoT-connected devices that integrate with data management software, inventory systems, and monitoring platforms to enhance industrial operations and supply chain traceability.

Mechanical Beam Scale

Mechanical beam scales are fundamental weighing instruments used in laboratories, shipping centers, and industrial facilities. Operating on the lever principle with a fulcrum between counterweights and load, they include triple beam balances, platform balances, and pan scales. Their durability and independence from power sources make them ideal for environments where digital scales are impractical.

Floor Scales

Industrial-grade floor scales handle heavy loads up to 600 kg (1322.77 lbs.) and beyond, commonly used for pallet weighing in shipping, warehousing, and manufacturing. Available as deck scales, drum scales, and portable models, they often feature counting, checkweighing, and data connectivity for logistics optimization and inventory management. Built to endure demanding conditions, these scales are essential in distribution centers and factories.

Counting Scale

Counting scales are specialized electronic instruments that simultaneously weigh and count uniform items. Their software calculates total counts by dividing gross weight by average item weight, significantly speeding inventory audits, quality checks, and packaging processes in electronics, metalworking, and pharmaceuticals. Features like data export and programmable tare functions enhance accuracy and traceability.

Crane Scales

Crane scales, or hanging scales, weigh large or awkward loads lifted by cranes or hoists in steel production, construction, and logistics. These heavy-duty digital scales convert force into weight measurements and often include remote displays, wireless data transmission, and overload protection. Available in digital, electronic, and hydraulic versions, they can be customized for high-capacity weighing tasks.

Washdown Scales

Washdown scales are waterproof weighing devices designed for hygienic environments requiring frequent cleaning. Meeting EHEDG and NSF standards, their IP ratings (IP65, IP67, or IP68) certify resistance to dust, water, and submersion. Commonly used in food processing and pharmaceuticals, these scales feature sealed strain gauges or EMFR technology for accuracy despite rigorous cleaning.

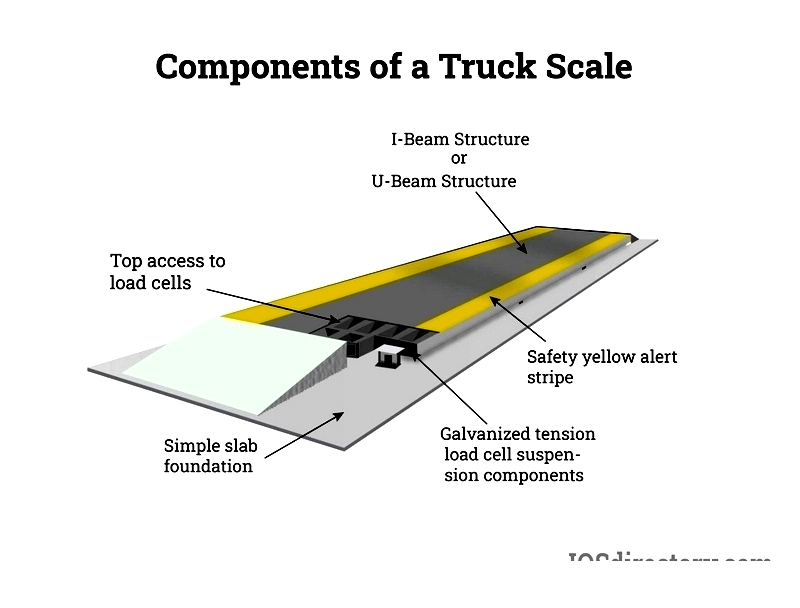

Truck Scales

Truck scales, or weighbridges, are essential for logistics, agriculture, and heavy industry. Their robust platforms and load cells measure vehicle weights to ensure compliance with legal limits and prevent overloading. Modern systems include weigh-in-motion technology for dynamic weighing and integration with data management software for automated records.

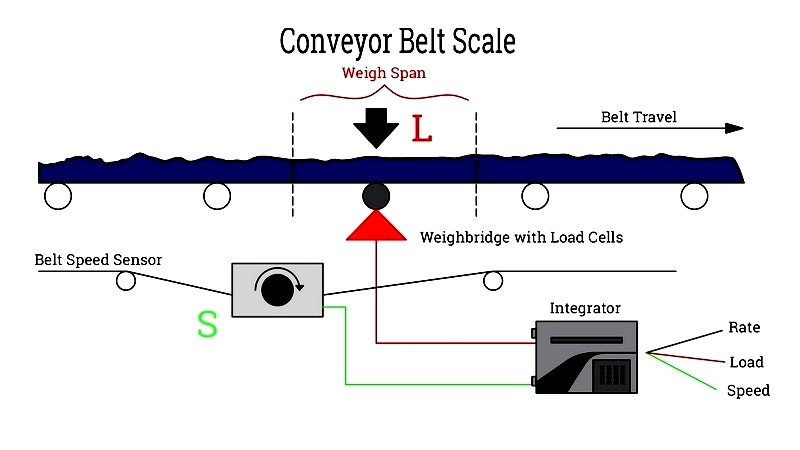

Conveyor Scale

Conveyor scales continuously weigh bulk materials on moving belts, crucial for mining, food production, and packaging. Using load cells and speed sensors, they provide real-time throughput measurements and integrate with automation systems for production optimization and regulatory compliance.

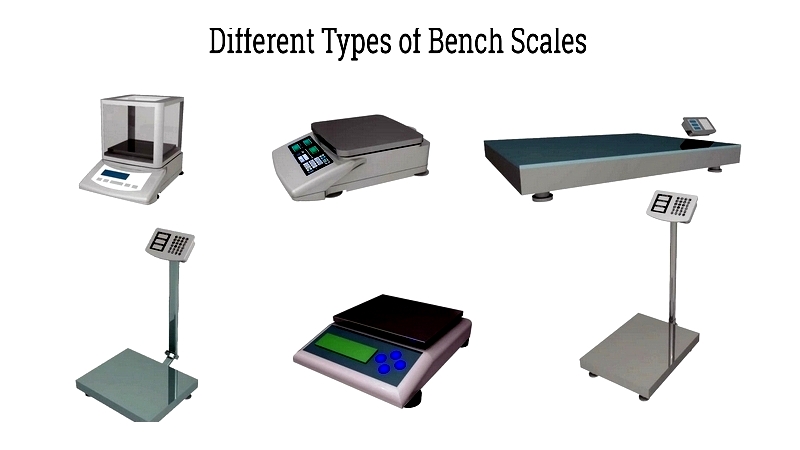

Bench Scales

Versatile bench scales suit small to medium applications in labs, shipping, and food service. Ranging from 1.5 kg to 60 kg (3.3 lbs. to 132.3 lbs.), they offer features like stainless steel construction, counting functions, and data connectivity. Options include waterproof, explosion-proof, and high-precision models for various environments.

The eight scale types described represent a portion of available options. Selecting the right equipment depends on application, environment, accuracy needs, and compliance requirements. Consulting industry experts ensures proper specification, installation, and maintenance for operational success.

Chapter 3: How Scales Work

Weighing devices have existed for millennia, evolving to meet commercial, industrial, and scientific demands. Early methods were mechanical, using balance scales and spring systems until the industrial revolution introduced more advanced technologies.