Introduction

This article provides an in-depth exploration of thermistors.

You will learn about various aspects including:

- What is a Thermistor?

- Thermistor Applications

- Thermistor Varieties

- Thermistor Manufacturing Process

- And more...

Chapter One – What is a Thermistor?

A thermistor is a semiconductor device that offers higher resistance than conventional conductors and is specifically designed to respond to temperature fluctuations. Its resistance varies based on the materials used in its construction. Typically made from metal oxides, binders, and stabilizers, these components are formed into wafers and then cut into chips. The material composition and ratios determine the thermistor's resistance characteristics and temperature response.

The term "thermistor" refers to temperature-sensitive resistors, valued for their precision in temperature measurement. There are two main types: Positive Temperature Coefficient (PTC) and Negative Temperature Coefficient (NTC) thermistors. NTC thermistors decrease resistance as temperature rises, while PTC thermistors increase resistance with temperature.

As passive components, thermistors provide an economical, accurate, and rapid method for temperature measurement by changing resistance in response to system temperature variations.

Thermistors serve to monitor device temperatures, directly impacting equipment performance and providing temperature detection and overload protection. They are widely used in circuits, components, and devices as a cost-effective temperature monitoring solution.

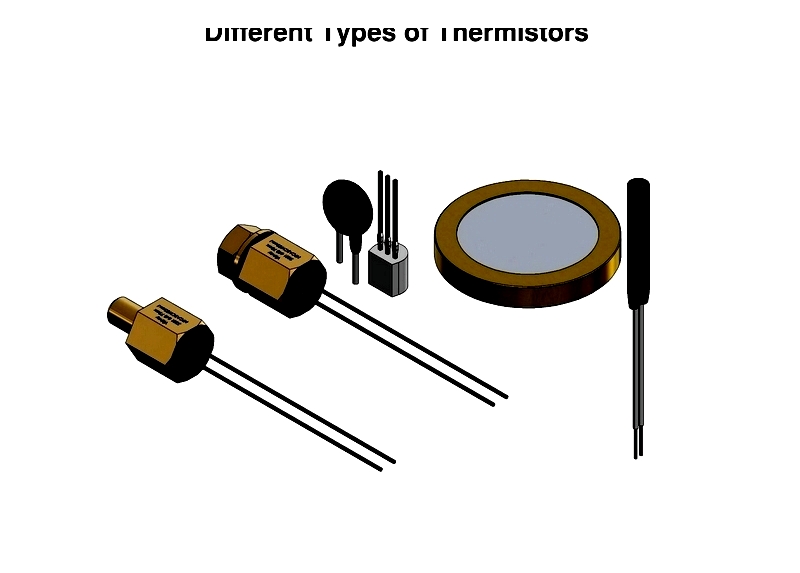

Available in various designs, thermistors include popular options like hermetically sealed, flexible (HSTH series), bolt-on, washer types, and self-adhesive surface-mount versions. HSTH thermistors feature a protective plastic polymer jacket that shields sensing elements from moisture and corrosion, ensuring durability and reliability.

Chapter Two – Thermistor Applications

Precise temperature monitoring is crucial in manufacturing and industrial automation systems. Effective temperature control directly affects product quality, safety, and efficiency across applications from food processing to electronics manufacturing. Thermistors, as specialized temperature sensors, offer consistent, predictable resistance changes in response to temperature variations, making them reliable for continuous temperature measurement in process control, equipment protection, and energy management.

Thermistors are used wherever accurate temperature measurement, thermal regulation, and control are needed—from industrial settings to household appliances. Their sensitivity makes them preferable to other sensors like thermocouples or RTDs. In HVAC systems, thermistors are vital for climate control, airflow management, and maintaining optimal ambient temperatures.

Thermistor sensors operate effectively between 32°F to 212°F (0°C to 100°C), suitable for residential, commercial, and light industrial applications. Class A thermistors deliver high accuracy for laboratory and medical equipment, while Class B thermistors serve general purposes where extreme precision isn't required. Their stability ensures long-term accuracy with minimal drift, reducing maintenance needs.

Key thermistor advantages include:

- High sensitivity to minor temperature changes

- Cost-effectiveness for mass production

- Excellent measurement consistency over multiple cycles

- Compact size for integration in small spaces

- Versatility for both NTC and PTC applications

Thermistors remain essential not only for traditional sensing but also for IoT and smart home technologies requiring real-time monitoring.

Thermostat Thermistors

Modern thermostats utilize sensitive NTC or PTC thermistors for accurate temperature feedback. In HVAC systems, thermistors serve as primary sensors in control circuits, enabling smart thermostats to optimize climate control and integrate with automation systems for energy efficiency.

Vehicle Thermistors

Automotive applications use thermistors to monitor oil and coolant temperatures, ensuring engine reliability. They contribute to safety by preventing overheating and are integrated into transmission systems, air intake sensors, climate controls, and EV battery management, providing critical temperature data to vehicle ECUs.

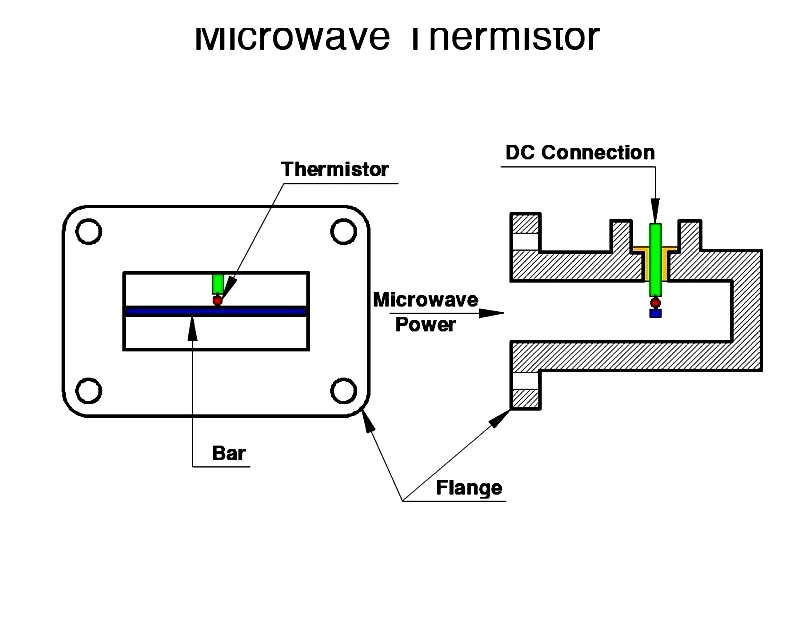

Microwave Thermistor

Microwaves employ thermistors for precise temperature regulation and thermal protection, preventing overheating during operation. This enhances safety and appliance longevity while meeting energy efficiency standards.

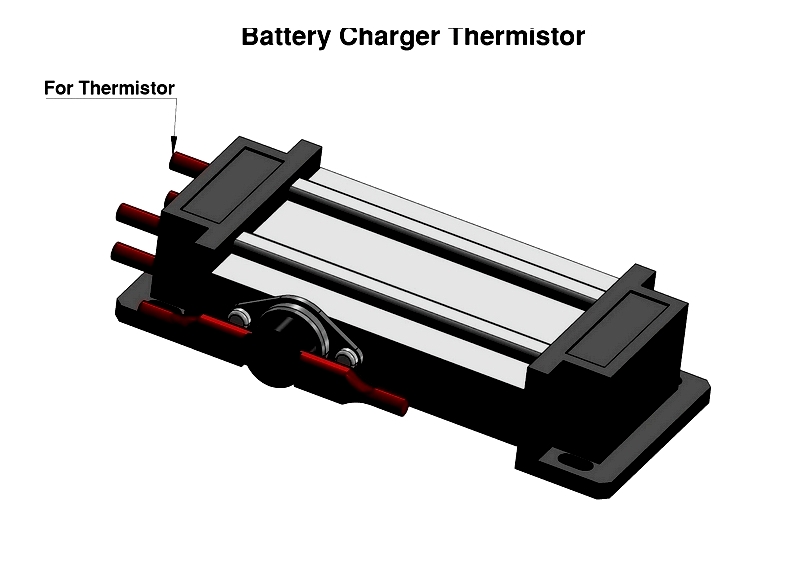

Rechargeable Batteries

NTC thermistors in battery systems monitor cell temperature during charging. They trigger safety cutoffs to prevent overheating, protecting lithium-ion and other battery types in consumer electronics, power tools, and electric vehicles.

Cell Phone Thermistors

Smartphones use thermistors for internal temperature monitoring, enabling thermal management of processors and batteries. This ensures safe operation and enhances device reliability and lifespan.

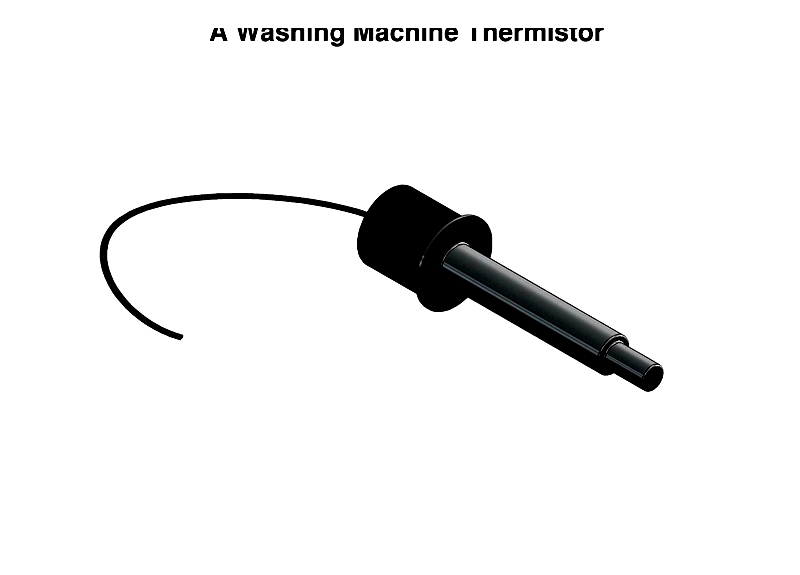

Washing Machine Thermistor

Washing machines utilize thermistors to maintain optimal water temperatures for different fabrics, improving cleaning efficiency while preventing component damage from overheating.

Surge Protector Thermistors

PTC thermistors in surge protectors detect electrical overloads, increasing resistance to interrupt current flow and protect connected electronics from voltage spikes.

Refrigerator Thermistors

Refrigerators use multiple thermistors to monitor freezer compartments and evaporator coils, optimizing cooling efficiency and defrost cycles. High-precision sensors help maintain ideal storage conditions while reducing energy consumption.