Introduction

Descriptions of Industrial Spring Types and Their Manufacturers

You will learn about:

- What Industrial Springs Are

- Types of Industrial Springs

- How Industrial Springs Are Made

- Applications of Industrial Springs

- And much more...

Chapter 1: What Are Industrial Springs?

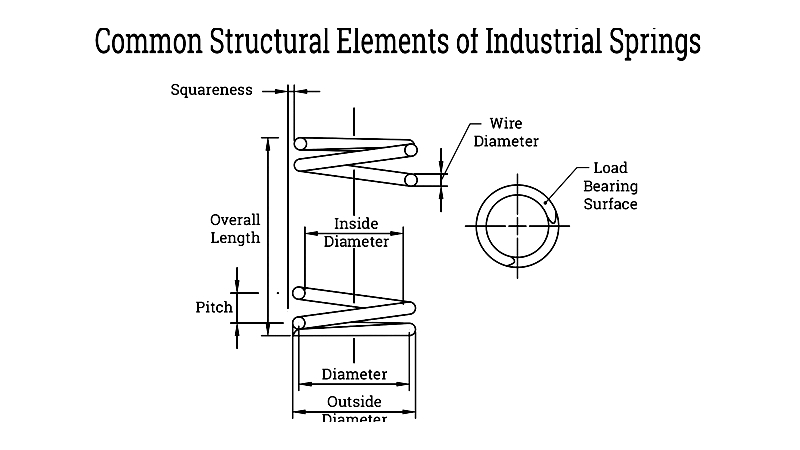

Industrial springs are heavy-duty springs with high load capacity that store energy when twisted, compressed, or pulled. When the deforming force is removed, they return to their original form. Like all springs, industrial springs deflect and support loads using potential energy when compressed, twisted, or stretched. While functioning similarly to watch and household springs, they use more durable materials to withstand greater stress.

Industrial springs operate under Hooke's Law, which explains elasticity. Elastic materials return to their original shape after stress. The restoring force, proportional to stretching, helps materials regain shape. In manufacturing, industrial springs endure prolonged stress from various factors.

The term "industrial springs" encompasses various springs providing flexibility and stability to machinery and structures. Essential for energy storage, shock absorption, and support, they require careful design and high-quality materials. Many applications demand custom-made industrial springs.

Chapter 2: Types of Industrial Springs

Most industrial springs resemble everyday springs but use robust materials for superior strength. While household springs support furniture and appliances, industrial springs control motion by resisting vibrations and absorbing shock. They protect equipment and workers from damage.

Although standard industrial springs exist, many applications require custom designs. Engineers adapt traditional springs for specialized manufacturing conditions, particularly for new equipment and processes.

The diverse types and designs of industrial springs enable vital functions. Manufacturers provide detailed information about spring capabilities for specific applications. Beginners should understand basic spring concepts when consulting manufacturers.

The Strongest Industrial Springs

The strongest industrial springs include compression, torsion, Belleville washers, extension, and wave springs. Defined by materials, design, dimensions, and application requirements, these springs typically remain hidden within mechanisms for motion control.

Industrial springs are classified by load application: linear/constant rate, variable rate, and constant force. Linear springs maintain a constant rate, while variable rate springs change throughout their length.

Heavy-duty industrial springs are larger and sturdier than typical springs. Their high-strength materials provide durability under heavy loads and harsh conditions. Industrial springs require significant force to deform, with spring rate being a key characteristic.

Compression Industrial Springs

Compression springs, made from round wire wound helically, use materials like carbon steel, stainless steel, and specialty alloys for elasticity, corrosion resistance, and fatigue strength. Their energy storage makes them the most versatile industrial springs.

When force compresses their coils, they store energy released upon load removal. Available in various shapes—cylindrical, conical, barrel, hourglass, variable pitch, and nested—they serve diverse applications.

Common uses include automobile suspension systems and aerospace landing gear, where they control forces and motion.

Extension Industrial Springs

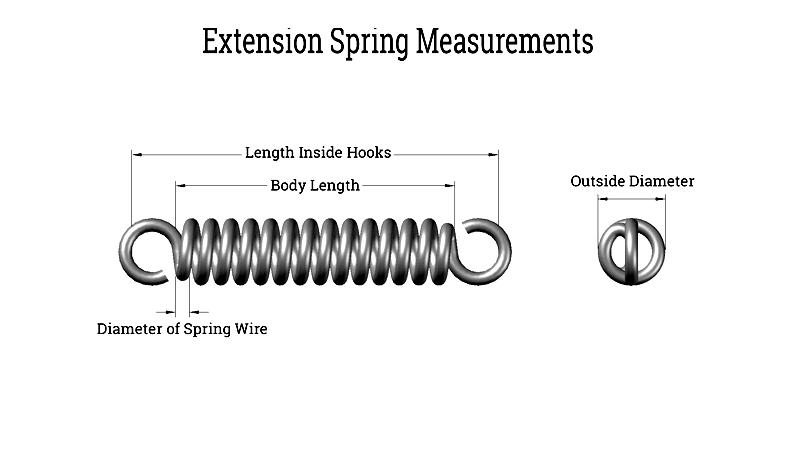

Extension springs resist tensile force, preventing attached components from separating. Stretching stores mechanical energy proportional to displacement (Hooke's Law). Industrial extension springs require careful selection based on wire diameter, coil dimensions, and hook length.

Coil count affects flexibility and stored energy. Initial tension keeps coils tight when unloaded, requiring overcoming before extension begins. Spring rate calculations include tension force for accurate load determination.

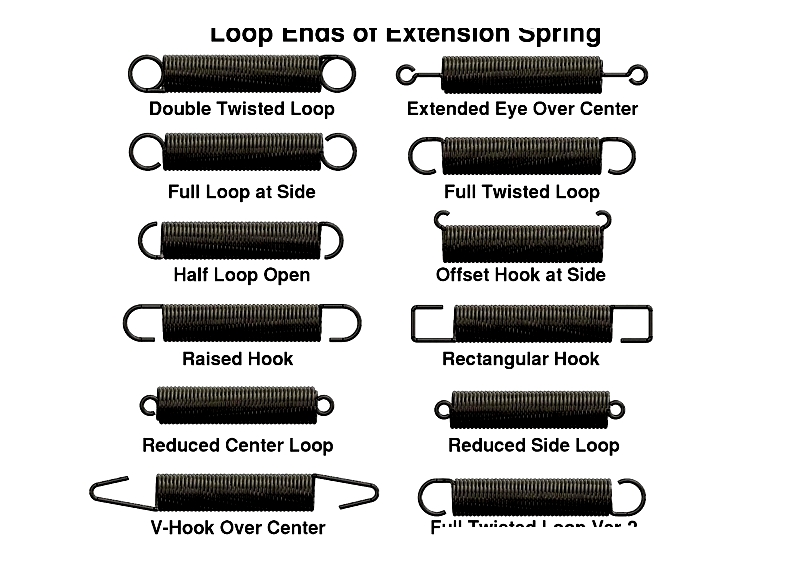

End types (hooks/loops) vary for industrial applications, with some springs designed without ends for increased lifespan and load capacity. Attachment methods include nuts, washers, and bolts.

Torsion Industrial Springs

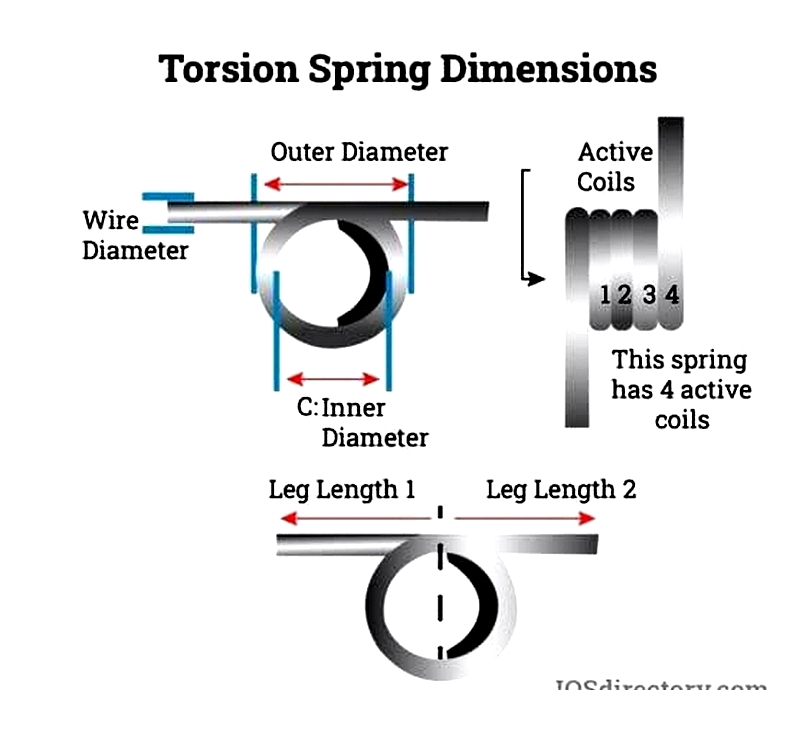

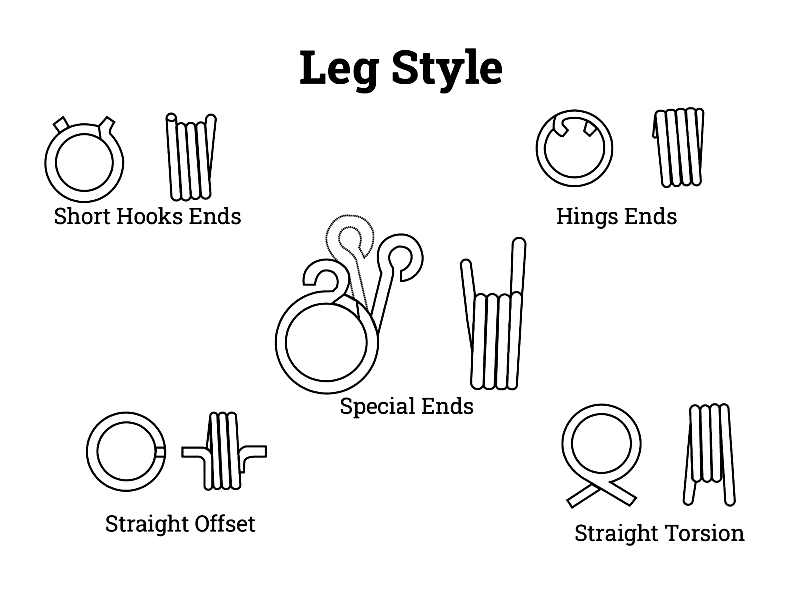

Torsion springs resist twisting force (torque) with helical coils and protruding arms. Rotation stores energy released when force is removed. Industrial torsion springs are closely wound, creating friction reduced by pitch in some designs.

Single torsion springs rotate left or right, while double torsion springs combine right- and left-hand coils for greater force. Their strength makes them ideal for aerospace, medical, and military applications.

End legs vary (straight, angled, axial, tangential) with custom designs for industrial use. Applications include automotive hinges, aerospace controls, and various industrial mechanisms.

Leaf Springs

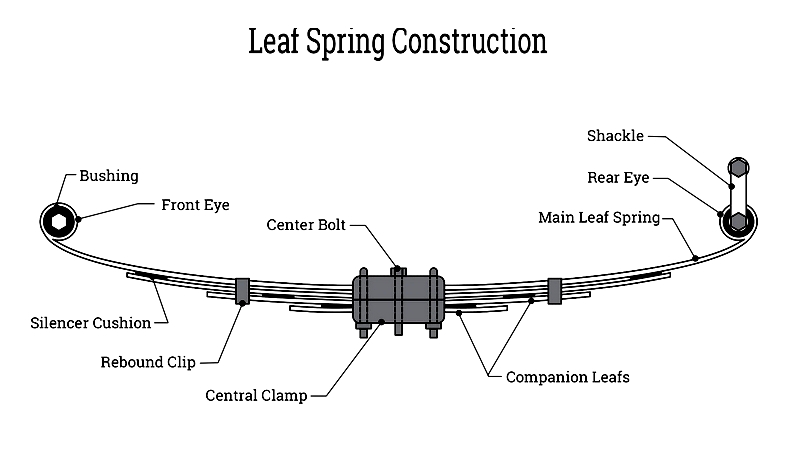

Leaf springs prevent vehicle bouncing/swaying, keeping wheels grounded. Made from parallel steel strips in semi-elliptical shapes, they distribute heavy loads through multiple layers.

Their simple construction ensures durability and cost-effectiveness. Though replaced in modern vehicles by coil springs, they remain in trucks as rear axle support, sometimes combined with other suspension types.

Types include semi-elliptical, quarter elliptical, three-quarter elliptical, and transverse, differing in connection methods and leaf arrangements.

Belleville Washers

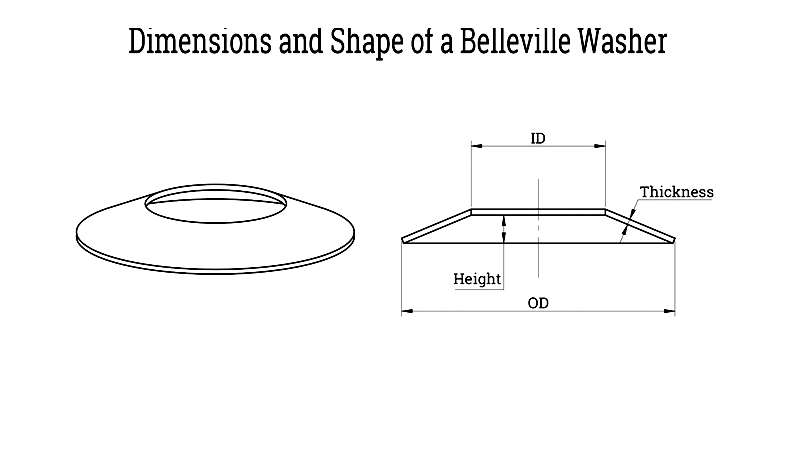

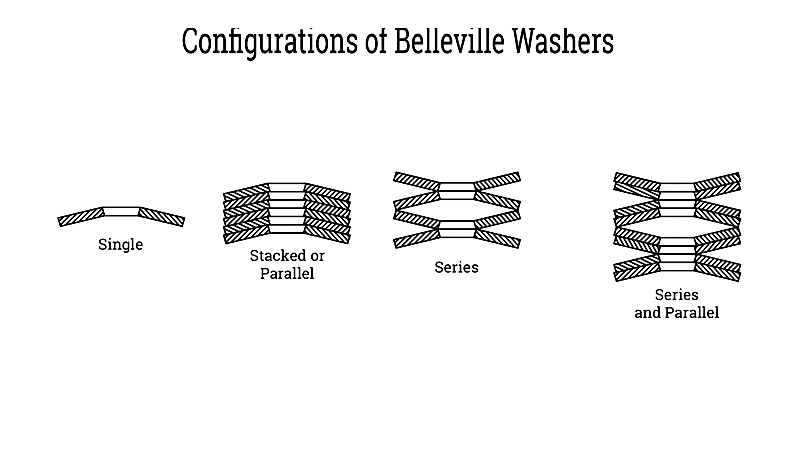

Belleville washers (disc springs) provide spring-like compression with their conical shape. Used in high-stress applications, they absorb vibrations and resist heavy loads, often stacked for multiple spring effects.

Unlike springs, they may not always rebound but apply consistent force. Configurations vary for different loads, with heat treatment enhancing properties. Their compactness provides stiffness in small spaces.

These represent just some industrial spring types. Others include constant force springs, wave springs, gas springs, and custom designs, each with unique characteristics for specialized applications.

Chapter 3: Spring Classification by Load

Industrial springs classify by applied load and construction method. Compression, torsion, and extension springs differ in load application, while construction types include coiled, flat, disc, and machined springs.

Spring load and rate measure force generation. Rate measures force per inch of deflection; load measures force during travel. Strength adjustments involve wire diameter, outer diameter, or coil count changes.

Load classification relates to force application and displacement: linear/constant rate, variable rate, and constant force. Load capacity depends on deflection height.

Key design measurements include free length (L), loaded height (H), and travel distance (x). These determine spring rate and working load capacity.

Linear Springs

Linear springs follow Hooke's Law with consistent diameter and constant spring rate. Their deflection remains proportional to applied force. Compression, extension, and torsion springs are linear types.

Design adjustments (coil diameter/pitch) alter load-def